Power Solutions with Soft & Rigid Copper Busbars

Precision-driven forming and machining ensure each component meets exact design standards from raw material to final assembly.

2500+ clients

Comprehensive electrical, dimensional, and performance tests guarantee reliability, safety, and long-term product stability.

What is a Flexible Copper Busbar

A flexible copper busbar is a type of electrical conductor, distinct from its traditional rigid counterparts, made from high conductivity copper.

Its design incorporates a series of thin copper laminates in a flat, flexible arrangement, allowing for much greater flexibility and adaptability in installation and use.

This innovative structure enables the busbar to bend, twist, and flex, accommodating a wide range of configurations and applications while maintaining excellent electrical conductivity and efficiency.

Flexible Copper Busbar Structure and Application

The flexible copper busbar is made of multiple layers of highly flexible flat thin copper sheets, and the outer layer is made of extrusion-wrapped heating ground layer. The insulation layer currently includes special polyurethane (PVC) and thermoplastic elastomer (TPE). Two materials.

TPE has low smoke and halogen-free properties. The insulation is black. Since the copper conductor can slide freely within the insulation layer, the non-threaded soft busbar has eyeless bending and torsion characteristics.

At the same time, the multi-layer flat conductor structure of the explosion-proof flexible copper busbar enables the same conductor cross-sectional area to carry a larger passing current, thus reducing the amount of conductor material, which not only reduces the weight, but also saves space.

Discover Our Custom Copper Busbars and Components

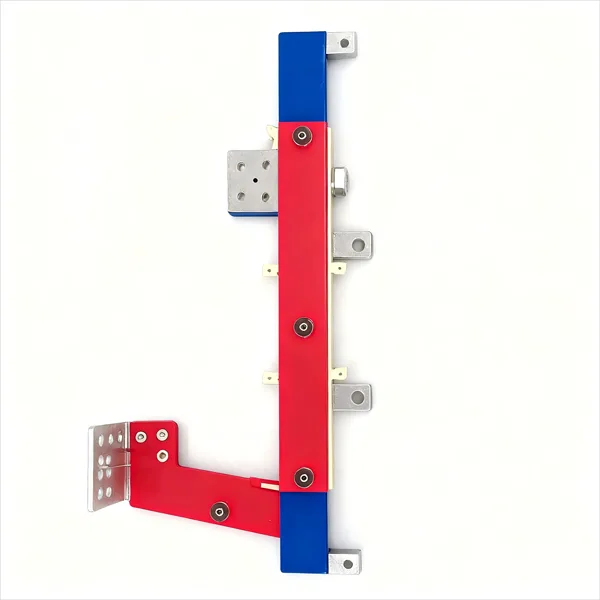

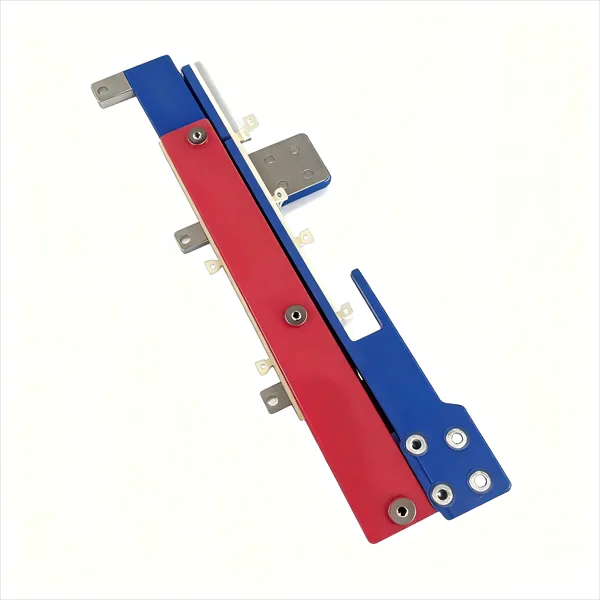

Rigid Copper Busbar

Rigid Copper Busbar

Rigid Copper Busbar

Rigid Copper Busbar

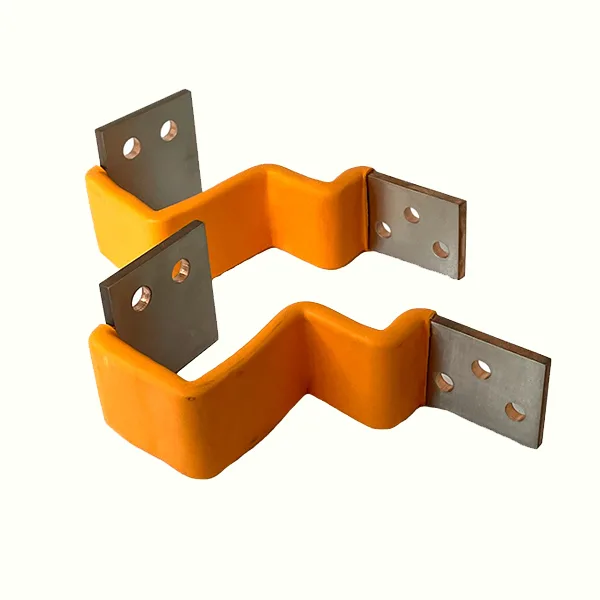

Flexible Copper Busbar

Flexible Copper Busbar

Flexible Copper Busbar

Flexible Copper Busbar

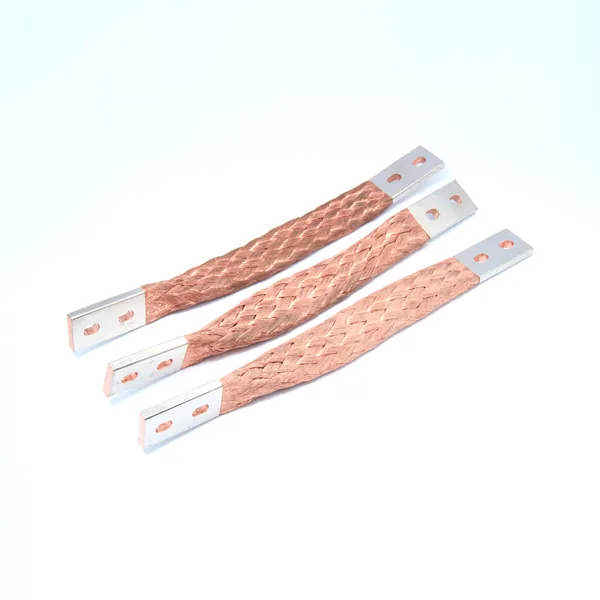

Braided Copper Busbar

Braided Copper Busbar

Braided Copper Busbar