In the rapidly evolving landscape of power distribution—from electric vehicle (EV) battery packs to massive industrial data centers—the debate between Rigid Busbars and Traditional Cables has never been more relevant. For decades, flexible cabling was the “default” choice due to its ubiquity and perceived ease of installation. However, as power densities increase and space becomes a premium commodity, rigid busbars have emerged not just as an alternative, but as the superior engineered solution for high-performance applications.

At JUMAI TECH, we specialize in the precision manufacturing of copper busbars and deep-drawn components. We see firsthand how transitioning to a rigid system can transform a chaotic “spaghetti” of wires into a streamlined, high-efficiency power backbone. This comprehensive guide explores every facet of the busbar vs. cable debate to help you determine which is the best fit for your specific project.

Table of Contents

Understanding the Fundamental Differences

Before diving into the technical metrics, it is essential to define what we mean by “Rigid Busbar.” Unlike a flexible cable, which consists of multiple strands of copper or aluminum encased in a thick layer of PVC or XLPE insulation, a rigid busbar is a solid bar of conductive material (typically C11000 ETP Copper).

Material Composition and Structure

Rigid busbars are designed to carry high currents in a fixed path. Because they are solid, they possess structural integrity that cables lack. This allows them to function as both a power conductor and a structural component within an enclosure. Cables, conversely, rely on their flexibility to snake through tight corners, but this flexibility comes at the cost of cross-sectional efficiency and heat dissipation.

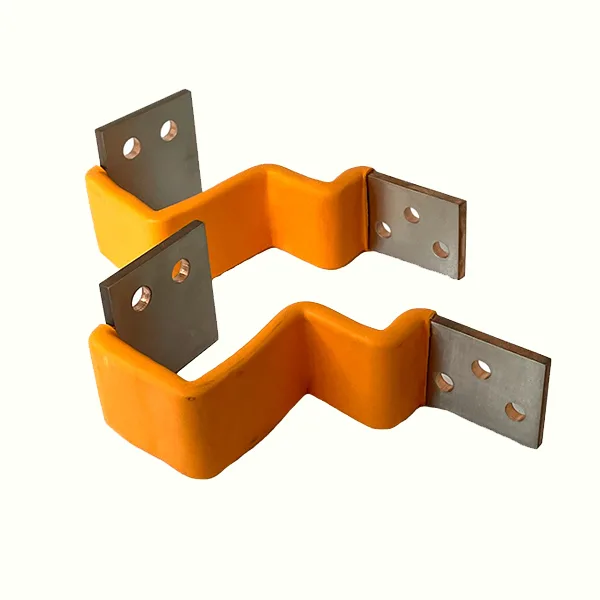

The Role of Precision Manufacturing

Modern busbars aren’t just flat bars; they are precision-engineered components. At JUMAI TECH, we utilize advanced CNC bending and deep-drawing techniques to create complex geometries that fit perfectly into your assembly. This level of precision eliminates the human error often associated with cutting and crimping heavy-gauge cables on-site.

Electrical Performance: Efficiency and Conductivity

When comparing the two, electrical efficiency is often the primary driver. Rigid busbars offer several inherent advantages in how they manage electrons and heat.

Lower Resistance and Voltage Drop

Because a rigid busbar is a solid piece of high-purity copper, it typically has lower contact resistance compared to a stranded cable of the equivalent cross-sectional area. In high-amperage applications (above 100A), even a fractional difference in resistance can lead to significant energy savings over the lifespan of the equipment.

Superior Heat Dissipation

One of the most critical advantages of rigid busbars is their surface-area-to-volume ratio. Cables are round and often bundled together, which traps heat in the center of the bundle.

- Surface Area: Busbars are flat, providing a larger surface area relative to their mass.

- Convection: This flat profile allows for better natural convection and radiant cooling.

- Operating Temperature: Because they run cooler, busbars can often carry more current than a cable of the same weight.

Skin Effect in High-Frequency Applications

While most power distribution is DC or 50/60Hz AC, high-frequency harmonics can cause the “skin effect,” where current flows primarily on the outer surface of the conductor. The wide, flat geometry of a rigid busbar provides more “skin” than a round cable, making it more efficient at handling these harmonics without overheating.

Space Optimization: The “Compactness” Factor

In modern engineering—especially in EV battery modules and server racks—space is the most expensive “component.” This is where rigid busbars provide a clear victory.

Reducing the Footprint

Cables require a specific bend radius. If you force a heavy-gauge cable into a sharp turn, you risk damaging the insulation or the copper strands. This means cable-based systems require large amounts of empty space just to accommodate the loops and turns of the wiring.

- Tight Bends: Rigid busbars can be bent at 90-degree angles with zero radius if designed correctly.

- Layering: Busbars can be stacked with thin layers of insulation (like epoxy coating or Heat Shrink), taking up a fraction of the volume required by equivalent cabling.

Better Airflow Management

In environments like data centers, airflow is critical for cooling. A massive bundle of cables acts as a “windbreak,” blocking the path of cooling fans. Rigid busbars, with their slim profile and predictable routing, allow for optimized airflow channels, reducing the energy cost of cooling the entire system.

Comparative Space Usage Data

| Feature | Rigid Busbar | Heavy-Gauge Cable |

| Cross-Sectional Shape | Rectangular (Optimized) | Circular (Inefficient) |

| Minimum Bend Radius | Near Zero (Fixed Geometry) | 6x to 10x Diameter |

| Stacking Ability | High (Interleaved) | Low (Bundling Heat Issues) |

| Space Efficiency | 30-40% Better | Baseline |

Weight and Material Economy

Many engineers assume cables are lighter because they are “flexible,” but the reality is often the opposite when looking at the total system weight.

Insulation-to-Copper Ratio

A high-voltage cable requires thick, heavy insulation to protect the strands and prevent arcing. In a rigid busbar system, we can use much thinner insulation (such as powder coating or specialized films) because the bars are fixed in place and won’t rub against each other. According to standards like IEC 61439, fixed conductors have different clearance requirements than moving parts.

Weight Savings in High-Current Paths

For a system requiring 2000A, the amount of copper and plastic required for cabling is significantly higher than a single, well-engineered rigid busbar. By reducing the “dead weight” of excess insulation, manufacturers can improve the range of EVs or the structural load limits of industrial buildings.

Installation Efficiency: Speed vs. Complexity

One of the most common misconceptions in the industry is that cables are “easier” to install because they are flexible. In reality, for high-current applications, flexibility becomes a liability during the assembly process.

The “Plug-and-Play” Nature of Busbars

Rigid busbars are manufactured to the exact specifications of your enclosure. At JUMAI TECH, we use precision CNC bending to ensure that every hole aligns perfectly with your terminals.

- Elimination of Measuring/Cutting: With cables, technicians must measure, cut, strip, and crimp on-site. This leads to variability and potential waste.

- Error Reduction: It is nearly impossible to install a custom-designed rigid busbar incorrectly. It only fits one way. This “poka-yoke” (error-proofing) design is a cornerstone of lean manufacturing.

- Tooling Requirements: Installing cables requires heavy-duty hydraulic crimpers and stripping tools. Rigid busbars typically only require standard torque wrenches to secure the bolted connections.

Labor Cost Comparison

In a study of industrial switchgear assembly, transitioning from cabling to a rigid busbar system reduced installation time by up to 50-70%. When you multiply this by hundreds of units in a production run, the labor savings often completely offset the higher initial engineering cost of the busbar.

Managing the “Spaghetti” Factor

As power systems grow in complexity, “cable management” becomes a nightmare. Large bundles of cables require trays, ties, and specialized routing to prevent them from tangling or interfering with other components. A rigid busbar system is inherently neat. It creates a clean, professional aesthetic that is not just about looks—it’s about serviceability. If a technician needs to inspect a connection, they can see it clearly without digging through a nest of wires.

Reliability and Mechanical Strength

In industrial environments, equipment is often subjected to vibration, thermal expansion, and short-circuit forces. Rigid busbars are engineered to thrive in these conditions.

Short-Circuit Resistance

When a short circuit occurs, massive electromagnetic forces are generated between conductors.

- Cables: Because they are flexible, cables can “whip” violently during a short circuit, potentially tearing out of their lugs or damaging surrounding sensitive electronics.

- Rigid Busbars: These systems are mechanically braced. A rigid copper bar, when properly supported by insulators, can withstand significantly higher short-circuit forces without moving. This makes them the standard choice for high-fault-current environments like power plants and data centers.

Resistance to Vibration

For automotive applications, particularly in Electric Vehicles (EVs), vibration is a constant threat. Constant micro-movements in cables can lead to “fretting” at the connection points or fatigue in the copper strands.

- Structural Integrity: Rigid busbars act as a part of the chassis. When bolted down, they have high resonance frequencies, meaning they are less likely to be damaged by the standard vibrations of a moving vehicle.

- Longevity: At JUMAI TECH, we often provide Deep-Drawn Components that integrate directly with busbars to create a seamless, vibration-resistant power path that outlasts traditional cable-and-lug assemblies.

Thermal Expansion Management

Both cables and busbars expand when they get hot. However, the expansion of a rigid busbar is predictable. Engineers can design “expansion bellows” or flexible links into the busbar run to absorb this movement. Cables expand in a less controlled manner, which can put stress on the terminal connectors, leading to loose joints—the number one cause of electrical fires.

Long-Term Cost of Ownership (TCO)

To truly answer “Which is better?”, we must look at the lifespan of the system, which is often 20 to 30 years for industrial infrastructure.

Maintenance and Inspection

The National Fire Protection Association (NFPA) emphasizes the importance of inspecting electrical connections.

- Thermal Imaging: It is significantly easier to perform infrared (IR) thermography on a rigid busbar. You can see the entire length of the conductor. In cables, the thick insulation can hide “hot spots” occurring within the strands until it is too late.

- Re-Torquing: Bolted busbar connections stay tight longer than crimped cable lugs, which can “cold flow” over time, leading to increased resistance.

Energy Savings and “Green” ROI

Because busbars generally operate at lower temperatures and have lower overall resistance (due to the elimination of multiple crimped joints), they are more energy-efficient.

- Efficiency: A 1% increase in efficiency might seem small, but for a 24/7 data center, that translates to thousands of dollars in saved electricity and reduced cooling costs annually.

- Recyclability: Rigid copper busbars are nearly 100% recyclable at the end of their life. Stripping the insulation from miles of cable is a labor-intensive and often messy process, making the “scrap value” of busbars much higher.

Technical Data: Cable vs. Busbar Lifetime Metrics

| Metric | Rigid Busbar System | Traditional Cable System |

| Design Life | 30+ Years | 15-20 Years (Insulation degradation) |

| Maintenance Frequency | Low (Annual Visual/IR) | Medium (Check for sagging/fretting) |

| Short-Circuit Rating | Very High | Moderate (Limited by bracing) |

| Voltage Drop | Minimal | Variable (Higher at joints) |

Manufacturing Precision: The JUMAI TECH Advantage

When you buy a cable, you are buying a commodity. When you invest in a Rigid Busbar, you are investing in a custom-engineered component. The “Better” in “Which is better?” often comes down to how well the conductor fits your specific application.

Precision Stamping Dies and Custom Geometries

Unlike cables, which are limited to a circular cross-section, rigid busbars can be stamped into complex shapes. We use Precision Stamping Dies to create contact points, mounting holes, and offset bends that would be impossible to replicate with bulky cable lugs.

- Consistency: Every piece is identical to the micron, ensuring that your assembly line never slows down due to fitment issues.

- Integrated Features: We can stamp “ribs” into the copper to increase mechanical stiffness without adding weight, a feat cables simply cannot match.

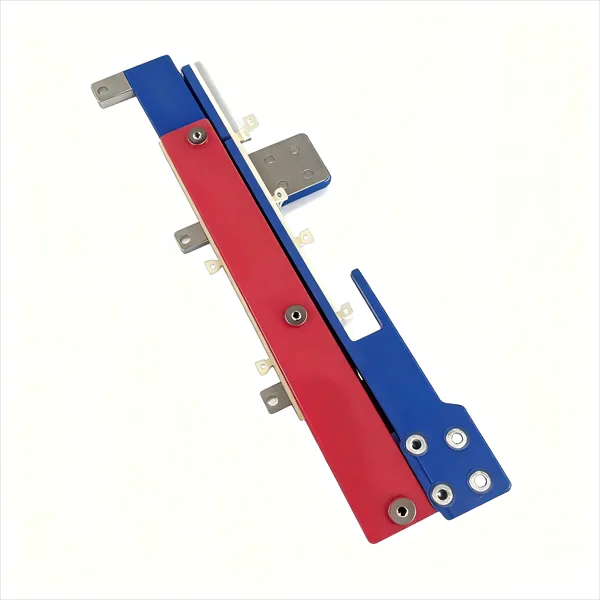

Deep-Drawn Components in Power Distribution

At JUMAI TECH, we often combine busbars with Deep-Drawn Components. For example, in EV battery modules, a busbar might need a “cup” or a recessed area to house a sensor or a fuse.

- Seamless Integration: By using deep-drawing technology, we can create these features out of a single piece of copper.

- Eliminating Joints: Every time you crimp a cable to a lug, you create a potential point of failure. A one-piece deep-drawn busbar eliminates these joints, drastically increasing reliability.

Material Science: Beyond Standard Copper

One of the most significant advantages of rigid busbars over cables is the ability to customize the surface chemistry of the conductor to suit the environment.

Plating Options for Enhanced Performance

While the core of the busbar is high-conductivity copper, the surface can be “tuned” through professional plating. This is much more effective on a solid bar than on stranded cable.

- Tin Plating: The industry standard for preventing oxidation and ensuring low contact resistance over decades of service.

- Silver Plating: Used in high-frequency or high-voltage applications (like switchgear) to provide the absolute lowest electrical resistance.

- Nickel Plating: Ideal for high-temperature environments or where harsh chemicals might be present, providing superior corrosion resistance compared to the PVC jacket of a cable.

Advanced Insulation Technologies

Cables rely on thick plastic jackets. Rigid busbars offer more sophisticated, space-saving insulation options:

- Epoxy Powder Coating: Applied electrostatically and cured in an oven, this provides a “skin-tight” insulation layer that is incredibly durable and allows for very tight clearances in compact electronics.

- Heat Shrink Sleeving: A cost-effective way to insulate straight runs while leaving joint areas exposed for easy maintenance.

- Integrated Spacers: Because the bars are rigid, we can use molded plastic insulators to “float” the bars in mid-air within an enclosure, allowing for maximum airflow.

Vibration and Harsh Environments: The Final Frontier

For industries like aerospace, rail, and automotive, the “Cable vs. Busbar” debate is decided by the environment.

Handling Mechanical Stress

Cables are prone to “strain hardening.” If a cable is constantly flexed or vibrated, the individual copper strands begin to microscopicly crack, eventually leading to a complete break. Rigid busbars, when designed with a “laminated” or “flexible link” section, can absorb these vibrations far more effectively.

- Resonance Control: We use FEA (Finite Element Analysis) to ensure the busbar’s natural frequency does not match the vibration frequency of the machine it is installed in.

- Fatigue Resistance: A solid, well-supported busbar has a fatigue life that can span decades, whereas cables in high-vibration areas often require replacement every 5–7 years.

Comparative Environmental Durability

| Environmental Factor | Rigid Busbar (Plated) | Standard Power Cable |

| High Temperature | Up to 150°C+ (Material Dependent) | 70°C – 105°C (Limited by PVC/XLPE) |

| Chemical Exposure | Excellent (Nickel/Tin Plating) | Moderate (Jacket can degrade) |

| UV Resistance | Infinite (Metal) | Poor to Moderate (Plastic embrittlement) |

| Vibration | High (with proper bracing) | Low (prone to strand fatigue) |

Total Cost of Ownership: The “Hidden” ROI

As we move toward the conclusion of this guide, it’s important to address the “Bottom Line.” While a custom-manufactured busbar from JUMAI TECH might have a higher initial design cost compared to a roll of cable, the Return on Investment (ROI) is realized through:

- Reduced Assembly Time: Lowering your factory labor costs.

- Zero Waste: No “off-cuts” or scrap copper from trimming cables.

- Energy Efficiency: Lower voltage drop means lower utility bills for the end-user.

- Reliability: Reducing the risk of expensive field failures and warranty claims.

Final Verdict: Which is Better?

In almost every high-performance, high-current, or space-constrained application, the Rigid Busbar is the superior technical and economic choice. Cables still have their place for “last-mile” connections or where extreme, unpredictable movement is required, but for the backbone of your power system, rigid copper is king.

At JUMAI TECH, we don’t just make parts; we solve power distribution challenges. Whether you need Precision Copper Busbars, Deep-Drawn Components, or Precision Stamping Dies, our team is ready to help you transition from the limitations of cabling to the limitless potential of rigid busbar systems.

Technical Deep Dive: The Physics of Connection

To understand why rigid busbars often outperform cables, we must look at the physics of the connection points. In any electrical system, the “joint” is the most common point of failure.

Bolted Joints vs. Crimped Terminals

When you use a cable, you must crimp a lug onto the end. This creates an interface between the stranded wire and the solid lug.

- The Crimp Problem: Over time, thermal cycling (heating and cooling) can cause the strands to shift, slightly loosening the crimp and increasing resistance. This is known as “stress relaxation.”

- The Bolted Advantage: Rigid busbars use bolted connections. Because both surfaces are solid copper, we can apply high torque to create a “gas-tight” joint. When we use Precision Stamping to create these connection holes, we ensure maximum surface contact area, which is vital for keeping temperatures low.

Skin Effect and Proximity Effect

In AC applications, electricity doesn’t flow uniformly through a conductor. It tends to flow near the surface (Skin Effect) and can be pushed to one side by nearby conductors (Proximity Effect).

- Geometry Matters: The rectangular profile of a rigid busbar has a much larger perimeter than a round cable of the same cross-section. This provides a more efficient path for AC current, reducing the “AC resistance” and the resulting heat.

- Predictable Inductance: Because busbars are held in a fixed position, their inductance is constant and predictable. This is critical for high-speed switching power supplies and modern motor drives where “stray” inductance can cause damaging voltage spikes.

Standards and Certifications: Navigating Compliance

When exporting products globally, compliance with international standards is non-negotiable. Rigid busbars make this process significantly smoother.

UL, CSA, and IEC Requirements

Standards such as UL 891 (for switchboards) and IEC 61439 have strict rules regarding “Clearance and Creepage.”

- Fixed Distances: Because rigid busbars do not move, it is easy to prove to a certifying body that the distance between conductors will remain constant.

- Cable Sag: Cables can sag over time or move during shipping, which might bring them too close to each other or the chassis, potentially violating safety standards.

Fire Safety and Halogen Content

Cables are wrapped in plastic. In a fire, some cable jackets release toxic halogen gases.

- Minimal Fuel Load: A rigid busbar system uses significantly less combustible material.

- Epoxy Safety: The epoxy coatings used by JUMAI TECH are often rated UL 94V-0, meaning they are self-extinguishing and contribute almost no fuel to a potential fire.

Detailed FAQ: What Engineers Ask JUMAI TECH

In my years as Editor-in-Chief and technical consultant, I’ve heard every concern imaginable. Here are the definitive answers to the most common questions regarding the transition from cable to busbar.

Q1: Is the “Skin Effect” really a concern for standard 60Hz power?

While the skin effect is minimal at 60Hz for small conductors, it becomes significant as current increases. For conductors carrying over 1000A, the center of a round cable is effectively “wasted” copper. A flat, rigid busbar uses its material much more efficiently, providing better performance-per-pound of copper.

Q2: How do you handle “Tolerances” in a rigid system?

This is the most common fear: “What if the busbar doesn’t fit?”

- The Solution: We design in “tolerance absorbers.” This can include oversized mounting holes, slotted connections, or a small section of Flexible Laminated Copper at the end of a long run. By combining rigid and flexible sections, you get the best of both worlds.

Q3: Aren’t busbars more expensive for small production runs?

If you are building only one unit, the “engineering time” to design a busbar might make it more expensive than a cable. However, for any production run over 10–20 units, the savings in assembly labor and the elimination of human error make the busbar the more economical choice.

Q4: Can busbars be used in mobile or high-vibration equipment?

Absolutely. Most modern Electric Vehicles (EVs) use rigid busbars for their main battery-to-inverter link. The key is proper bracing. A cable vibrating at its own resonance can actually do more damage to a terminal than a rigid bar that is securely bolted to the frame.

Summary Data Table: The Ultimate Comparison

| Feature | Rigid Busbar (JUMAI TECH) | Traditional Multicore Cable |

| Current Density | High (Efficient cooling) | Moderate (Heat trapped in core) |

| Voltage Drop | Low (Solid material, few joints) | Higher (Cumulative at every crimp) |

| Assembly Speed | Fast (Drop-in fit) | Slow (Cut, strip, crimp, route) |

| Short-Circuit Rating | Excellent (Mechanical bracing) | Poor (Subject to “whipping”) |

| Space Requirement | Minimal (Tight bends allowed) | Large (Requires bend radii) |

| Airflow Path | Clean / Predictable | Obstructed / Chaotic |

| End-of-Life Value | High (Pure copper scrap) | Lower (Contaminated by plastic) |

Partnering with JUMAI TECH for Your Next Project

The decision between Rigid Busbar vs. Cable isn’t just about selecting a conductor; it’s about choosing an engineering philosophy. By moving to a rigid system, you are choosing precision, reliability, and long-term efficiency.

At JUMAI TECH, we are more than just a manufacturer. We are an extension of your engineering team. Whether you are in the automotive sector, renewable energy, or industrial automation, our expertise in Precision Copper Busbars, Deep-Drawn Components, and Precision Stamping Dies ensures that your power distribution is a competitive advantage, not a bottleneck.

Let’s Build the Future of Power Together

Stop wrestling with heavy cables and messy wiring looms. Contact JUMAI TECH today to see how our custom-engineered solutions can streamline your design and boost your bottom line.

[Visit www.deepdrawtech.com to request a technical consultation or a quote on your custom copper busbar project.]