Precision Tooling for Reliable Manufacturing

Precision-driven forming and machining ensure each component meets exact design standards from raw material to final assembly.

2500+ clients

Comprehensive electrical, dimensional, and performance tests guarantee reliability, safety, and long-term product stability.

What Are Precision Tooling & Mold Components

Precision tooling and mold components are high-accuracy metal parts designed to support advanced forming and stamping operations. Unlike standard tooling, they provide exceptional durability, dimensional stability, and consistent performance under demanding production conditions.

These components are engineered to withstand repeated mechanical stress, ensuring long-term reliability and precise forming results across automotive, electronics, and industrial applications.

Advanced tooling allows for complex geometries, optimized material usage, and enhanced operational efficiency, producing molds and dies that combine strength, precision, and longevity.

Tooling & Mold Component Structure and Applications

Precision tooling and mold components are typically fabricated from high-grade steels, alloys, or specialty metals, selected based on required hardness, wear resistance, and thermal stability.

The manufacturing process includes precision CNC machining, heat treatment, and surface finishing to maintain dimensional accuracy, tight tolerances, and long service life. Components may also undergo coatings or treatments to improve corrosion resistance, reduce friction, or enhance durability under high-load forming operations.

These tooling and mold components are widely used in deep drawing, stamping, and forming applications for automotive, electronics, and industrial manufacturing. Their precision, consistency, and durability allow manufacturers to reduce downtime, improve product quality, and optimize production efficiency.

Discover Our Custom Tooling & Mold Components

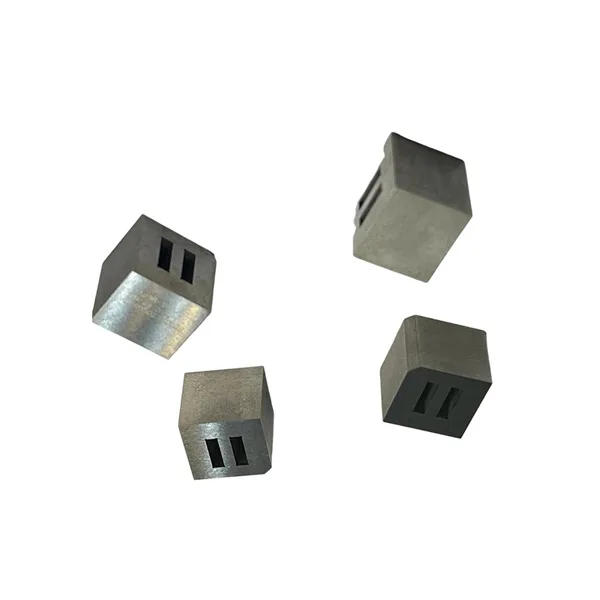

Custom Tooling Components

Custom Tooling Components

Custom Tooling Components

Custom Tooling Components

Custom Tooling Components

Custom Tooling Components

Custom Tooling Components

Custom Tooling Components

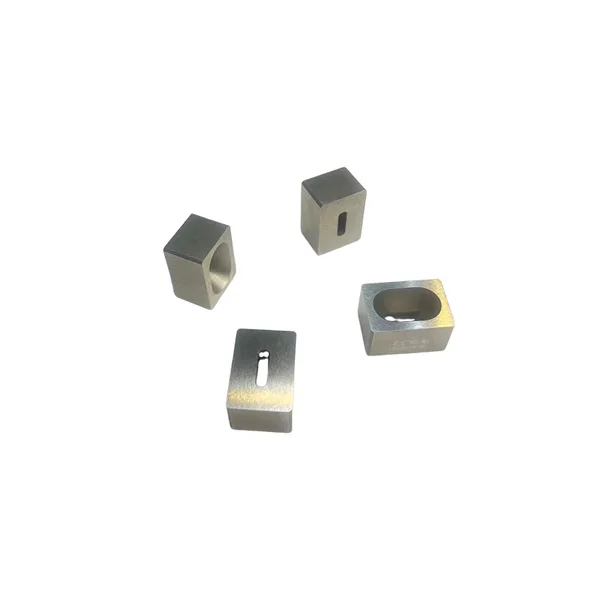

Custom Mold Components

Custom Mold Components

Custom Mold Components

Custom Mold Components

Custom Mold Components

Custom Mold Components

Custom Mold Components