High-Precision Stamped & Drawn Components

Precision-driven forming and machining ensure each component meets exact design standards from raw material to final assembly.

2500+ clients

Comprehensive electrical, dimensional, and performance tests guarantee reliability, safety, and long-term product stability.

What Are Precision Deep-Drawn Components

Precision deep-drawn components are high-accuracy metal parts formed through advanced stamping and drawing processes. Unlike standard stamped parts, they achieve complex shapes with tight tolerances, consistent thickness, and superior surface finish.

These components are engineered to withstand mechanical stress while maintaining dimensional stability, making them ideal for demanding applications in automotive, electronics, and industrial equipment.

The deep-drawing process allows for intricate geometries and optimized material usage, producing components that combine strength, precision, and lightweight efficiency.

Deep-Drawn Component Structure and Application

Precision deep-drawn components are typically fabricated from high-quality stainless steel, copper alloys, or other specialty metals, depending on the required mechanical and electrical properties.

The forming process includes multiple stages of controlled stamping and drawing, often with annealing between stages to maintain ductility and prevent cracking. This ensures components retain uniform wall thickness, high dimensional accuracy, and excellent surface quality.

Advanced surface treatments and coatings can be applied to enhance corrosion resistance, wear resistance, or conductivity, depending on application requirements.

Deep-drawn components are widely used in electronic housings, connectors, automotive parts, and precision industrial assemblies. Their high precision, consistency, and strength allow designers to reduce part count, optimize assembly, and improve overall system reliability.

Discover Our Custom Deep-Drawn Components

Type-C Series

Type-C Series

Sensor Series

Sensor Series

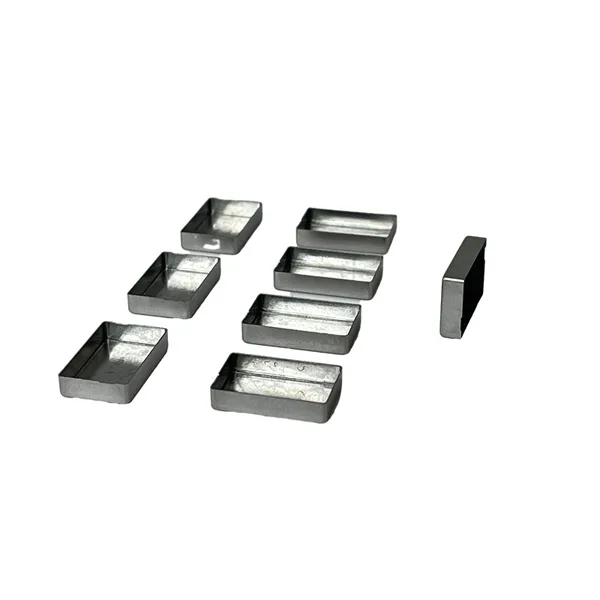

Shielded Shell Series

Shielded Shell Series

Shielded Shell Series

Shielded Shell Series

Air Conditioning Thermostat Series

Air Conditioning Thermostat Series

Voice Coil Motor Series

Voice Coil Motor Series

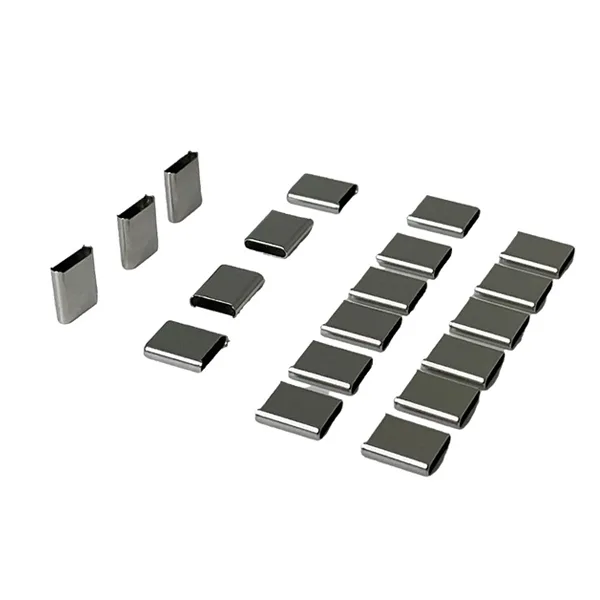

Square Shell Series

Square Shell Series

Round Stretch Series