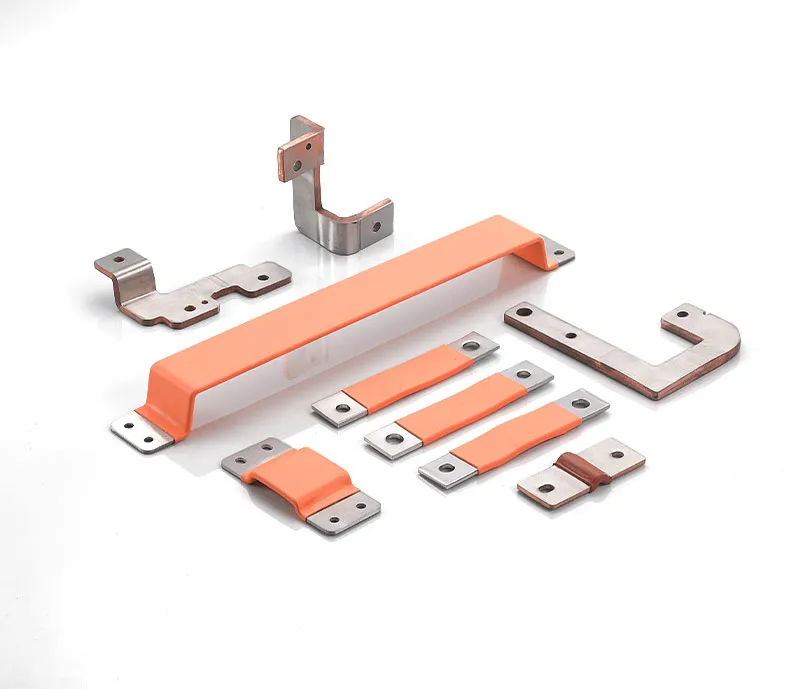

In the rapidly evolving landscape of global power distribution, the engineering choices we make today define the reliability and efficiency of tomorrow’s infrastructure. At JUMAI TECH (www.deepdrawtech.com), we have spent years mastering the art of metal transformation—from intricate Deep-Drawn Components to high-tonnage Precision Stamping Dies. However, few components play as critical a role in the integrity of electrical systems as the Rigid Busbar. As industries ranging from renewable energy to heavy manufacturing demand higher power densities and unwavering reliability, the limitations of traditional cabling systems are becoming glaringly apparent.

For high-voltage switchgear manufacturers and electrical engineers, the transition from flexible cable to a Rigid Busbar system is not merely a design preference; it is a strategic upgrade that fundamentally alters the performance characteristics of the equipment. Having worked with Precision Copper Busbars for over a decade, we have witnessed firsthand how upgrading to rigid systems solves complex thermal, spatial, and mechanical challenges. This article serves as a definitive guide, exploring the technical supremacy of rigid busbar architecture and why it is the inevitable future for high-performance switchgear.

Table of Contents

The Engineering Imperative: Why Rigid Busbars?

Before diving into the specific benefits, it is essential to understand what differentiates a Rigid Busbar from other conductors. Unlike flexible cables or braided straps, rigid busbars are solid, pre-formed bars of copper or aluminum that serve as the central artery for electrical current distribution.

The Physics of Efficiency

In high-voltage applications, efficiency is governed by the ability to minimize resistance and manage the physical byproducts of current flow—primarily heat and electromagnetic forces. Rigid Busbars offer a geometric advantage. Their rectangular cross-section provides a higher surface-area-to-volume ratio compared to round cables. This geometric reality allows for the “skin effect” (where alternating current tends to flow near the surface of the conductor) to be managed more effectively, optimizing the usage of the conductor material.

At JUMAI TECH, when we engineer Precision Copper Busbars, we utilize high-purity oxygen-free copper (such as C10100 or C11000) processed through our advanced Precision Stamping Dies. This ensures that the grain structure of the metal remains intact even after punching and bending, maintaining maximum conductivity (IACS ratings). The shift to rigid systems is driven by the need for deterministic performance—knowing exactly how the conductor will behave under peak loads and fault conditions.

Benefit 1: Superior Thermal Management and Current Density

The most immediate operational advantage of a Rigid Busbar is its thermal performance. In high-voltage switchgear, heat is the enemy of longevity. Excessive heat degrades insulation, increases resistance (which generates more heat), and can lead to catastrophic failure.

Optimized Heat Dissipation

A cylindrical cable effectively traps heat within its core, especially when bundled. The insulation layers required for high voltage further act as thermal blankets, preventing heat escape. Conversely, a Rigid Busbar is typically uninsulated or coated with a thin layer of epoxy powder, allowing for direct convective and radiative cooling.

The flat surface of a busbar acts as a heat sink. When installed in switchgear, the vertical orientation of the bars promotes natural air convection—hot air rises along the flat face of the bar, pulling cooler air in from the bottom. This allows engineers to push higher amperages through a smaller cross-sectional area compared to cable.

Ampacity Comparison Data

To illustrate this, consider the following comparison between standard copper cabling and copper rigid busbars under similar ambient conditions (35°C ambient, 30°C rise).

| Metric | 500 MCM Copper Cable (x2 per phase) | Rigid Copper Busbar (6mm x 100mm) |

| Cross-Sectional Area | ~500 mm² (Total) | 600 mm² |

| Surface Area for Cooling | Low (Circular geometry limits radiation) | High (Wide flat surfaces maximize radiation) |

| Current Carrying Capacity (Approx) | 760 Amps | 1,050 Amps |

| Space Required | High (Requires spacing for heat dissipation) | Low (Compact stacking) |

| Termination Heat | High (Crimping creates resistance points) | Low (Flat-to-flat bolted connection) |

Data Source Reference: Based on standard DIN 43671 and NEC ampacity tables.

The Role of Precision Manufacturing

At JUMAI TECH, our Deep-Drawn Components and busbar fabrication processes ensure that the surface finish of the busbar is impeccable. A smoother surface not only aids in better electrical contact at joints but also ensures uniform heat radiation. By switching to rigid busbars, switchgear manufacturers can often reduce the amount of copper required to achieve the same ampacity rating, resulting in significant cost savings despite the material being premium.

Benefit 2: Enhanced Short-Circuit Strength

In the realm of high-voltage switchgear, a short circuit is a violent event. The fault current can spike to tens of thousands of amperes in a fraction of a second. This surge creates immense electromagnetic forces that attempt to push the conductors apart or pull them together, depending on the phase relationship.

Withstanding Lorentz Forces

Cables, by their nature, are flexible. Under the stress of a short circuit fault (e.g., 50kA or 65kA for 1-3 seconds), cables can “whip” violently. This mechanical movement can strip insulation, damage internal switchgear components, or even cause an arc flash explosion.

Rigid Busbars, however, are engineered structures. They are mounted on high-strength insulators (often made from BMC or SMC materials) that brace the bars against these electromagnetic forces. Because the bar is rigid, it does not deform or whip.

Mechanical Integrity and Design

The stiffness of the bar is calculated based on the maximum peak short-circuit current ($I_{pk}$). The formula for force between two parallel busbars is:

Where:

- F is the force in Newtons.

- I is the current.

- L is the length.

- d is the distance between bars.

Because Rigid Busbars can be placed at precise, fixed distances and firmly braced, the system’s ability to withstand these forces is significantly higher than cable systems. At JUMAI TECH, we use our Precision Stamping Dies to create exact mounting holes and reinforcement points, ensuring that when the busbar is bolted to the insulator, it acts as a unified structural element. This mechanical rigidity is non-negotiable for critical infrastructure like substations and data centers where downtime is not an option. Refer to IEEE Standard 605 for detailed design guides on busbar station design.

Benefit 3: Space Optimization in Switchgear Design

Modern industrial real estate is expensive, and data center white space is at a premium. Clients are demanding smaller footprints for their electrical distribution equipment without sacrificing power capacity. This is where Rigid Busbar design shines.

The 90-Degree Advantage

Cables have a minimum bending radius, typically 8 to 12 times the cable diameter. This physical limitation dictates the size of the switchgear cabinet. You cannot simply turn a large high-voltage cable at a sharp angle; attempting to do so compromises the insulation and the conductor strands.

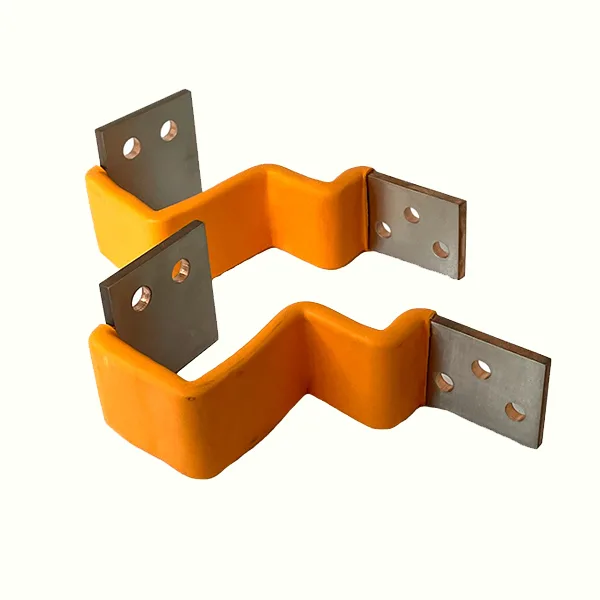

Rigid Busbars, processed through advanced CNC bending machines like the ones we operate at JUMAI TECH, can be bent at sharp 90-degree angles with zero loss of integrity. This allows for complex, three-dimensional routing of power within a very tight enclosure.

Improving Airflow and Component Density

By utilizing rigid bars, engineers can design “sandwiched” phases or compact layered architectures.

- Reduced Enclosure Size: A switchgear cabinet utilizing rigid busbars can be up to 25% smaller than an equivalent cable-based system.

- Cleaner Internal Layout: Cables often result in a “spaghetti” mess that obstructs airflow and makes maintenance difficult. Busbars provide a clean, visually organized layout that improves airflow efficiency for other components like breakers and sensitive electronics.

We often combine our Deep-Drawn Components (such as custom shielding cans or housing) directly with the busbar assembly. Because the busbar geometry is fixed and precise, we can design deep-drawn shields that fit within millimeters of the conductor, maximizing safety and minimizing space, a feat impossible with the unpredictable sagging of cables.

Benefit 4: Long-Term Reliability and Maintenance Reduction

The Total Cost of Ownership (TCO) for high-voltage switchgear is heavily influenced by maintenance requirements and failure rates. The weak point in any electrical system is the connection point.

The Problem with Crimp Connections

Cable systems rely on crimped lugs. A crimp is a mechanical deformation that relies on pressure to maintain conductivity. Over time, thermal cycling (heating up during the day, cooling at night) causes expansion and contraction. This creates “micro-movements” within the crimp, eventually leading to loosening, increased resistance, hot spots, and failure.

The Stability of Bolted Busbar Joints

Rigid Busbar connections are metal-to-metal (often plated with tin, silver, or nickel). They are secured using high-tensile steel bolts and Belleville washers (conical spring washers).

- Torque Retention: The Belleville washers maintain constant tension on the joint even as the copper expands and contracts thermally.

- Surface Contact: The flat, machined surfaces of a rigid busbar joint provide a massive contact area compared to a lug.

- Plating Technology: At JUMAI TECH, we offer various plating options for our busbars. Tin plating prevents oxidation in standard environments, while silver plating offers the lowest contact resistance for high-performance applications.

Maintenance Schedules

Switchgear utilizing Rigid Busbars requires significantly less maintenance. While cable connections need regular infrared thermography scans and re-torquing, a properly assembled busbar joint is virtually maintenance-free for years. The reduction in potential failure points (crimps) drastically increases the Mean Time Between Failures (MTBF) for the entire switchgear lineup. For more on electrical reliability, the International Electrotechnical Commission (IEC) provides standards such as IEC 61439 regarding low-voltage switchgear and controlgear assemblies which favor these rigid constructions.

Benefit 5: Modular Scalability and Installation Efficiency

Time is money on a production floor or a construction site. One of the overlooked benefits of Rigid Busbar systems is the speed of assembly and the potential for modularity.

Prefabricated Precision

Cabling is often an artisanal process done on-site: cutting to length, stripping, crimping, and routing. This introduces human error. If a technician nicks the insulation or crimps a lug improperly, the fault may not be discovered until the system is energized.

Rigid Busbars are manufactured to tolerance within our factory using Precision Stamping Dies. Every hole, every bend, and every length is identical.

- Plug-and-Play Assembly: When the busbars arrive at the assembly line, they fit perfectly. There is no cutting or adjustment required.

- Scalability: Rigid busbar systems allow for modular extension. If a facility needs to add more capacity, additional sections can be bolted onto the existing busbar system using splice plates. Extending a cable system usually involves running entirely new cables from the source.

Reducing Labor Costs

While the upfront material cost of a fabricated copper busbar might be higher than raw cable, the installation labor savings are massive. A complex power distribution block that might take an electrician 4 hours to wire with cables can be assembled with pre-formed busbars in 20 minutes.

JUMAI TECH’s Contribution to Modularity

We support our clients by offering kit-based delivery. We produce the Precision Copper Busbars, the associated Deep-Drawn Components for mounting, and the stamping parts for brackets. We deliver these as a complete assembly kit. This integration means our clients spend less time sourcing parts and more time assembling high-quality switchgear.

JUMAI TECH: Your Partner in Precision Manufacturing

Understanding the benefits of rigid busbars is the first step; executing the manufacturing requires a partner with deep expertise. At JUMAI TECH (www.deepdrawtech.com), we do not just bend metal; we engineer conductivity.

Core Capabilities

- Precision Stamping Dies: We design and manufacture our own dies. This is critical for busbar production. A poor quality die results in burrs on the punched holes. In high-voltage applications, a sharp burr acts as a stress concentration point for the electric field (corona discharge), leading to arcing. Our dies ensure perfectly smooth, radius-edge holes.

- Deep-Drawn Components: Our expertise in deep drawing allows us to create custom terminal covers, insulating cups, and complex connector housings that integrate seamlessly with your rigid busbar design.

- Customization: Whether you need laminated busbars for low inductance, flexible braided links for vibration isolation, or solid rigid bars for main power distribution, we have the machinery to deliver.

Quality Assurance

Every Rigid Busbar leaving our facility undergoes rigorous testing. We check dimensional accuracy using CMM (Coordinate Measuring Machines), verify plating thickness, and conduct conductivity tests. We understand that in your industry, a micrometer of deviation can result in a megawatt of failure.

Conclusion: The Solid Choice for the Future

The transition from cable to Rigid Busbar technology represents a maturation of electrical design. It moves the industry away from the variability of manual wiring toward the precision of engineered structural conductors.

By switching to rigid busbars, you gain:

- Thermal Efficiency: Higher amps, cooler operation.

- Safety: Unmatched short-circuit withstand capabilities.

- Space: Compact designs that save valuable floor space.

- Reliability: Joints that last decades, not years.

- Speed: Faster, error-free installation.

At JUMAI TECH, we are ready to assist you in this transition. Whether you are redesigning an existing switchgear line or developing a new high-voltage solution, our team of experts in Precision Copper Busbars, Deep-Drawn Components, and Precision Stamping Dies is at your service.

Ready to upgrade your power distribution architecture?

Contact our engineering team today at www.deepdrawtech.com to discuss your specifications and receive a complimentary DFM (Design for Manufacturing) analysis of your busbar needs. Let us help you build the solid backbone your equipment deserves.