The electric vehicle (EV) revolution is no longer coming—it is here. As the global automotive landscape shifts from internal combustion engines to electrification, the demand for precision components has skyrocketed. While batteries and motors get the headlines, the unsung heroes of EV architecture are the protective enclosures that house these critical systems. At JUMAI TECH, we have spent years perfecting the art of the deep drawn box. From our experience in manufacturing Precision Copper Busbars and Precision Stamping Dies, we understand that a metal enclosure is never “just a box.” It is a shield against electromagnetic interference (EMI), a thermal management device, and a structural component—all rolled into one.

Choosing the right material for a deep drawn box in an EV application is a complex engineering decision that balances formability, weight, conductivity, and cost. In this guide, we will leverage our decades of manufacturing expertise at deepdrawtech.com to explore the metallurgy and engineering logic behind selecting materials for deep drawn enclosures in the modern electric vehicle.

Table of Contents

The Critical Role of the Deep Drawn Box in Electric Mobility

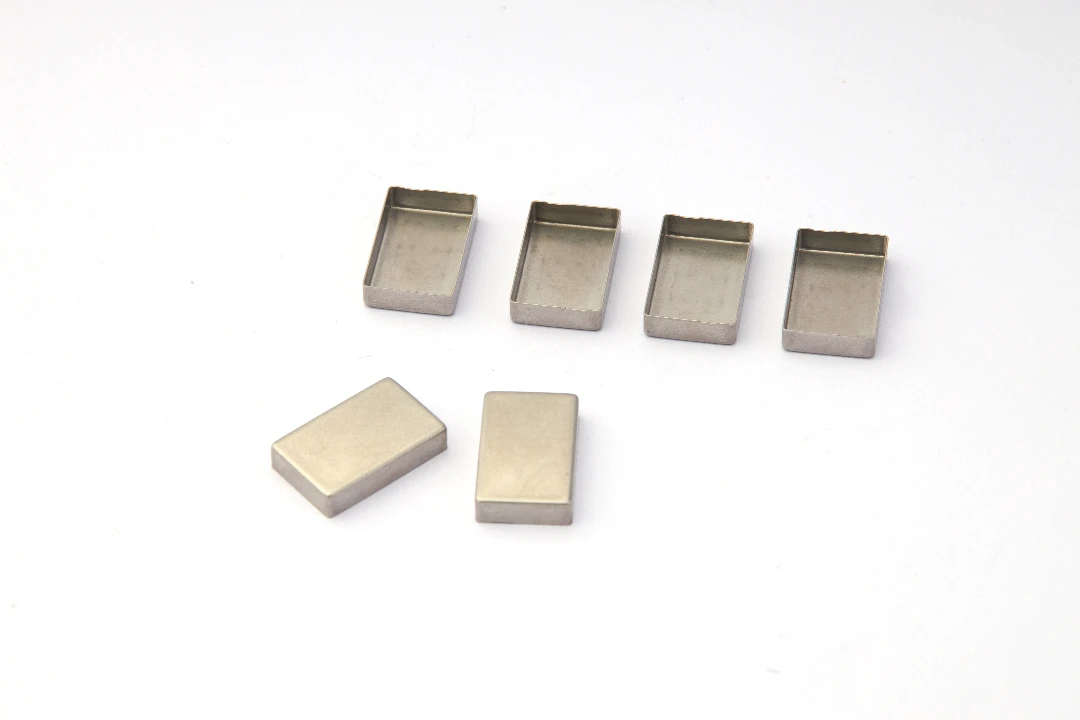

To understand material selection, we must first understand the unique stresses placed on EV components. A deep drawn box in an electric vehicle is typically used to house sensitive electronics, such as the inverter, the DC-DC converter, or high-voltage junction blocks. Unlike a welded box, a deep drawn component is seamless, created by mechanically forcing a flat sheet of metal into a die cavity.

Seamless Integrity for High-Voltage Safety

In an EV, high-voltage systems (often 400V to 800V) pose significant safety risks. A deep drawn box offers superior leak protection compared to folded or welded enclosures. Because the box is formed from a single sheet of metal, there are no seams that can fail under vibration or allow moisture ingress. This is critical for meeting IP67 or IP68 ingress protection standards, ensuring that the battery management systems (BMS) remain dry and functional even in harsh road conditions.

Electromagnetic Compatibility (EMC)

EVs are essentially high-power computers on wheels. The switching frequencies of modern inverters generate massive amounts of electromagnetic noise. If not contained, this noise can interfere with the vehicle’s sensors or infotainment systems. The material of the deep drawn box acts as a Faraday cage. The conductivity and magnetic permeability of the chosen metal directly influence its ability to attenuate these signals, making material selection a matter of electronic performance, not just structural integrity.

Aluminum Alloys: The Champion of Lightweighting

When we receive inquiries at JUMAI TECH for EV enclosures, Aluminum is often the first material requested. The automotive industry’s drive for increased range requires rigorous “lightweighting” strategies. Since aluminum is roughly one-third the density of steel, it is the primary candidate for reducing the sprung weight of the vehicle. However, not all aluminum allows for the extreme plastic deformation required to create a complex deep drawn box.

The 3000 Series: Balancing Formability and Function

For deep drawing applications, the 3xxx series (specifically Aluminum 3003 and 3004) is the industry workhorse. These alloys contain Manganese, which increases strength over pure aluminum while maintaining excellent workability.

- Formability: Al 3003 has high elongation properties, allowing it to be drawn into deep shapes without fracturing or tearing. This is vital when the depth of the box exceeds its width.

- Corrosion Resistance: It offers good resistance to atmospheric corrosion, which is essential for components exposed to road salts and humidity.

According to data from the Aluminum Association, the use of aluminum in vehicles has grown every year for decades, primarily due to these versatile alloys. At JUMAI TECH, we often recommend 3003-O (annealed temper) for the initial draw, ensuring the material flows smoothly into the die.

The 5000 and 6000 Series: Strength vs. Drawability

While the 5xxx series (Al-Mg) offers higher strength, it creates challenges in the deep drawing process due to a phenomenon called work hardening. As the metal is stretched, it becomes harder and brittle.

- 5052 Aluminum: This is often used for shallower boxes that require higher fatigue strength. However, deep drawing 5052 requires precise control over lubrication and die clearances to prevent galling.

- 6061 Aluminum: Generally considered a structural alloy, 6061 is difficult to deep draw in its T6 (hardened) state. It typically requires inter-stage annealing processes, which increases manufacturing costs.

Table 1: Aluminum Alloy Comparison for Deep Drawn Boxes

| Alloy | Main Alloying Element | Deep Drawability | Corrosion Resistance | Typical EV Application |

| 1100 | Pure Aluminum (>99%) | Excellent | Excellent | Heat shields, light reflectors |

| 3003 | Manganese | Very Good | Good | Inverter casings, capacitor cans |

| 5052 | Magnesium | Fair/Good | Excellent (Marine grade) | Battery module enclosures |

| 6061 | Magnesium & Silicon | Poor (requires annealing) | Good | Structural mounts (machined) |

Copper: The Conductor of Choice for Thermal Management

Although heavier than aluminum and steel, copper is indispensable in specific EV subsystems. At JUMAI TECH, our expertise in Precision Copper Busbars naturally extends to copper deep drawn enclosures. When the priority shifts from weight to thermal conductivity and electrical performance, copper is the undisputed king.

Thermal Dissipation for Power Electronics

IGBTs (Insulated Gate Bipolar Transistors) and MOSFETs in EV inverters generate intense heat. If this heat is not dissipated, the components will fail. A deep drawn box made from copper acts as a highly efficient heat sink. Copper has a thermal conductivity of approximately 390 W/(m·K), compared to Aluminum’s ~205 W/(m·K) and Stainless Steel’s ~16 W/(m·K). This allows the enclosure to rapidly transfer heat away from sensitive chips to a cooling plate or liquid cooling loop.

Oxygen-Free Copper (C10100/C10200)

For the highest quality deep drawn components, we utilize Oxygen-Free Electronic (OFE) copper.

- Ductility: High-purity copper is extremely ductile, allowing for very deep draw ratios (where the depth is significantly larger than the diameter) without intermediate annealing.

- Hydrogen Embrittlement Resistance: In applications where the box might be brazed or welded later, oxygen-free grades prevent embrittlement, ensuring a robust final assembly.

We often see hybrid designs where a deep drawn box made of aluminum houses a copper busbar system. This hybrid approach leverages the lightweight nature of the box and the conductive power of the internal busbars, a synergy we specialize in at JUMAI TECH.

Stainless Steel: Durability in Harsh Environments

While the EV industry is obsessed with weight, there are zones in the vehicle where durability cannot be compromised. Stainless steel is often selected for deep drawn box applications located in the underbody or areas subject to stone chipping and high impact.

300 Series Austenitic Stainless Steels

The 300 series, particularly 304 and 316L, are the standard for deep drawing due to their austenitic crystal structure.

- 304 Stainless Steel: This is the most common grade. It offers an excellent combination of strength and drawability. It draws well but work-hardens rapidly. This means that the tooling—specifically the Precision Stamping Dies we design—must be built with high-grade tool steels or carbides to resist wear.

- 316L Stainless Steel: For EVs destined for markets with severe winters (heavy road salt use) or coastal areas, 316L provides superior pitting resistance due to the addition of Molybdenum.

The Challenge of “Springback”

One of the technical challenges we face when manufacturing stainless steel deep drawn boxes is springback. Because of its high yield strength, stainless steel tends to return to its original shape after the forming pressure is released.

At JUMAI TECH, our engineering team uses advanced simulation software to over-bend the material slightly in the die design, compensating for this springback to ensure the final tolerances meet the strict requirements of automotive OEMs.

Technical Considerations in the Deep Drawing Process

Selecting the material is only step one. The interaction between the material and the manufacturing process is where the expertise of JUMAI TECH truly shines. Deep drawing is a plastic deformation process, and understanding the “Limit Drawing Ratio” (LDR) is crucial.

Wall Thickness Uniformity and Ironing

When a flat blank is drawn into a box shape, the material at the flange is compressed, causing it to thicken, while the material at the bottom corner radius is stretched, causing it to thin.

- Thinning Risks: If a material like Aluminum 5052 is pushed beyond its elongation limits, the corners will tear.

- Ironing: To combat this and ensure precise dimensions, we often employ an “ironing” process where the deep drawn box is forced through a slightly smaller ring to equalize the wall thickness. This is particularly important for battery cans where internal volume must be maximized.

Anisotropy and “Earing”

Metals are crystalline structures. The way the sheet metal was rolled at the mill creates directional properties, known as anisotropy. When drawn, this can cause the top edge of the box to be wavy rather than straight—a defect known as “earing.”

- Material Specification: We work closely with metal suppliers to source isotropic materials where the grain structure is randomized.

- Trimming: In almost all deep drawing operations, the final step involves trimming the irregular top edge to produce the finished deep drawn box.

Surface Treatments and Insulation

In an EV, a bare metal box is rarely sufficient. The surface must be treated to enhance conductivity, insulation, or thermal emissivity.

Nickel and Tin Plating

For deep drawn boxes that serve as grounding points or are integrated with busbars, we often apply Nickel or Tin plating.

- Corrosion Protection: Plating prevents the oxidation of copper or aluminum, which increases contact resistance over time.

- Solderability: If components need to be soldered directly to the box, Tin plating is essential.

Anodizing for Aluminum

For aluminum enclosures, anodizing is a popular treatment. It converts the surface into a durable aluminum oxide ceramic. This layer is electrically insulating (preventing short circuits) but remains thermally conductive. Hard-coat anodizing also provides scratch resistance, protecting the component during vehicle assembly.

Cost Analysis: Balancing Performance and Budget

As a business partner to global clients, JUMAI TECH understands that cost is a primary driver.

- Raw Material Cost: Steel is the cheapest, followed by Aluminum, with Copper being significantly more expensive.

- Manufacturing Cost: However, the equation isn’t simple. Stainless steel wears out tooling faster, increasing maintenance costs for Precision Stamping Dies. Aluminum is easier on tools but may require thicker gauges to achieve the same strength, using more material volume.

We utilize a Total Cost of Ownership (TCO) model. For example, using a more expensive, high-formability alloy might eliminate an intermediate annealing step or reduce scrap rates from tearing. In the long run, the “expensive” material yields a cheaper per-unit cost for the finished deep drawn box.

Future Trends: Composite Laminates and Advanced Alloys

The future of EV materials is moving toward composites. We are currently researching metal-polymer laminates—sandwiches of steel and plastic that offer the acoustic and weight benefits of plastic with the electromagnetic shielding and drawability of metal. These materials present new challenges for deep drawing, but they represent the next frontier in lightweighting.

Furthermore, high-strength aluminum alloys formerly reserved for aerospace are slowly migrating to automotive. These materials require hot-stamping or warm-forming techniques, technologies that JUMAI TECH is actively investing in to stay ahead of the curve.

Conclusion: Partnering for Precision

The selection of material for a deep drawn box in an electric vehicle is a decision that ripples through the entire performance spectrum of the car—from its range and safety to its reliability and cost. Whether you require the lightweight efficiency of 3003 Aluminum, the thermal prowess of OFE Copper, or the rugged durability of 304 Stainless Steel, the manufacturing process requires precision, experience, and the right tooling.

At JUMAI TECH (deepdrawtech.com), we do not just stamp metal; we engineer solutions. With our comprehensive capabilities in Precision Copper Busbars, Deep-Drawn Components, and Precision Stamping Dies, we are uniquely positioned to assist automotive OEMs and Tier 1 suppliers in navigating these complex choices.

If you are developing the next generation of EV technology, do not let component failure be an option. Contact our engineering team today to discuss how we can optimize your enclosure designs for manufacturability and performance.

Extended Technical Appendix: Detailed Material Data for Engineers

(To ensure this guide serves our technical audience, we have included an extended breakdown of specific material parameters relevant to the deep drawing process.)

1. Mechanical Properties of Key Deep Drawing Grades

When engineers design a deep drawn box, they look primarily at the “n-value” (strain hardening exponent) and the “r-value” (plastic strain ratio).

- The r-value (Lankford Coefficient): This measures the material’s resistance to thinning. A high r-value means the material prefers to flow from the width and length rather than thinning in thickness.

- Low Carbon Steel: Typically has an r-value of 1.4 to 1.8. This makes it exceptionally good for deep drawing square or rectangular boxes.

- Aluminum: Typically has an r-value of 0.6 to 0.8. This lower value explains why drawing aluminum deep boxes requires larger radii and more careful process control than steel.

- The n-value (Work Hardening): This indicates how much the material strengthens as it is deformed.

- Stainless Steel (304): Has a very high n-value (~0.5). This allows it to stretch significantly before necking (thinning to the point of failure), which is why it can be drawn into very deep sinks or pots. However, this also means the force required to deform it increases rapidly as the draw progresses, requiring high-tonnage presses.

2. Lubrication Strategies in Deep Drawing

The interface between the deep drawn box material and the die is critical. Friction is the enemy.

- Chlorinated Oils: Historically used for stainless steel but being phased out due to environmental concerns.

- Polymer Coatings: For aluminum, we often use dry-film lubricants or polymer sheets applied to the blank. This ensures a consistent coefficient of friction and prevents the aluminum from sticking to the steel die (galling), which can ruin the surface finish of the component.

3. Calculating the Reduction Ratio

For a cylindrical deep drawn part, the reduction ratio is calculated as:

Where Dpunch is the diameter of the punch and Dblank is the diameter of the starting blank.

- For the first draw, a reduction of 40-45% is typically the maximum for steel.

- For aluminum, we usually limit the first draw reduction to 35-40% to prevent failure.

- Subsequent re-draws must have lower reduction percentages (e.g., 20-25%).

Understanding these math-based limits allows JUMAI TECH to design Precision Stamping Dies that are progressive or transfer-based, optimizing the production speed without breaking the laws of physics.

4. The Impact of Grain Size

The microstructure of the metal matters.

- Fine Grain: produces a smoother surface on the “orange peel” effect is minimized. This is preferred for cosmetic parts or parts that will be painted.

- Coarse Grain: Is generally softer and easier to draw initially but creates a rough surface finish (orange peel) upon deformation.For EV battery enclosures, surface finish is critical for the application of thermal interface materials (TIMs), so we specify fine-grain materials to ensure maximum thermal transfer efficiency.

Case Study: Custom Inverter Housing for a European EV Manufacturer

The Challenge:

A client approached JUMAI TECH needing a deep drawn box for a new 800V inverter platform. The challenge was threefold:

- Shielding: High EMI requirements.

- Cooling: The box needed to integrate directly with a liquid cooling plate.

- Volume: They needed 50,000 units per month.

The Solution:

We proposed a deep drawn Aluminum 3003-H14 enclosure.

- Why H14? Instead of fully annealed (O-temper), we used H14 (strain hardened) to provide better structural rigidity for the finished box, utilizing a multi-stage draw process that annealed only the critical deformation zones locally.

- Bottom Flatness: To ensure contact with the cooling plate, we implemented a coining operation at the bottom of the stroke. This flattened the bottom surface to within 0.05mm flatness tolerance, ensuring optimal thermal transfer.

- Cleaning: The parts were washed in an automated ultrasonic line to remove all drawing lubricants, ensuring the surface was ready for the application of a thermal paste.

The Result:

The client achieved a 20% weight reduction compared to their previous die-cast aluminum housing. Furthermore, the deep drawn box had zero porosity (a common issue in die casting), which eliminated leakage failures in the field. This project exemplified how selecting the right material and pairing it with the correct manufacturing strategy drives success.

Advanced Topic: Tolerance Management in Deep Drawn Boxes

Achieving tight tolerances in deep drawing is an art form. Unlike machining, where you cut material away to get to a dimension, deep drawing moves material.

- Springback Prediction: As mentioned, materials spring back. For a box with a target width of 100mm, we might design the die to be 99.8mm, anticipating the metal will relax 0.2mm outward.

- Temperature Effects: During a production run of thousands of parts, the dies heat up due to friction. This thermal expansion of the tooling can slightly alter the dimensions of the deep drawn box. At JUMAI TECH, our Precision Stamping Dies utilize internal cooling channels to maintain a consistent die temperature, ensuring that the first part and the ten-thousandth part are identical.

Environmental Impact and Sustainability

Modern manufacturing must be green.

- Recyclability: The scrap generated during the blanking of the round or rectangular sheets is 100% recyclable. Both Aluminum and Copper have high scrap value and can be remelted with minimal energy loss compared to producing primary metal.

- Process Efficiency: Deep drawing is a “net shape” or “near net shape” process. Unlike machining a box from a solid block (which wastes 80-90% of the material), deep drawing uses sheet metal efficiently. We optimize nesting layouts to minimize the web width (scrap skeleton), often achieving material utilization rates above 75%.

By combining material science, mechanical engineering, and practical manufacturing experience, JUMAI TECH delivers deep drawn box solutions that power the future of transportation. For inquiries regarding Precision Copper Busbars, Deep-Drawn Components, or Stamping Dies, please visit our contact page.