In the rapidly evolving landscape of power distribution, electrical engineers and system architects face a perennial dilemma: how to transmit increasing amounts of power within shrinking spatial footprints. For decades, the choice has been a battle between the traditional flexibility of stranded power cables and the engineered precision of rigid busbars. At JUMAI TECH, where we specialize in manufacturing high-precision copper busbars, deep-drawn components, and stamping dies, we have witnessed a significant shift in the industry. We are seeing a migration away from “cable spaghetti” toward the structured, efficient, and thermally superior architecture of rigid busbar systems.

However, the decision is rarely black and white. Choosing between a rigid busbar and a power cable requires a deep understanding of current density, thermal dynamics, mechanical stress, and total cost of ownership (TCO). Whether you are designing a high-voltage switchgear cabinet, an Electric Vehicle (EV) battery pack, or a massive data center distribution unit, the choice of conductor will dictate the reliability and longevity of your system. In this comprehensive guide, we will dissect the technical nuances of Rigid Busbar technology versus traditional cabling to help you determine the optimal solution for your specific application.

Table of Contents

The Fundamental Differences in Conductor Architecture

To understand the performance gap, we must first look at the physical architecture of these two conductors. They are not merely different shapes of copper; they represent fundamentally different approaches to electron flow.

Defining the Rigid Busbar

A Rigid Busbar is a solid metal bar—typically composed of high-purity copper (C11000/C10200) or electrical-grade aluminum—used to conduct electricity within a switchboard, distribution board, substation, or battery bank. Unlike cables, which rely on insulation and flexibility, busbars rely on rigidity and surface area.

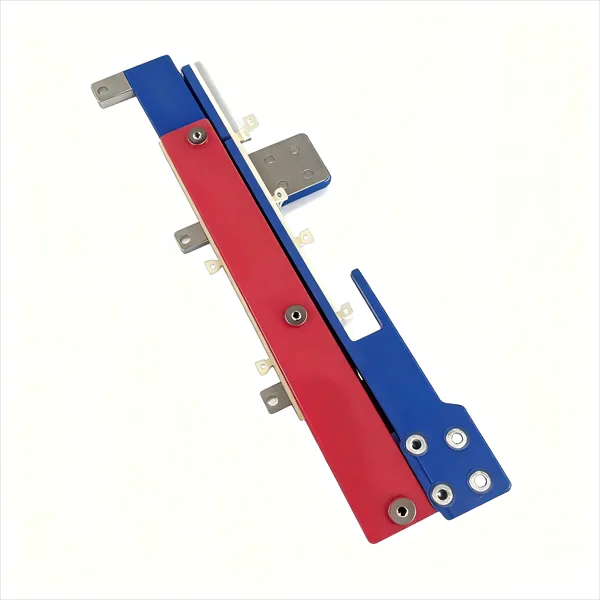

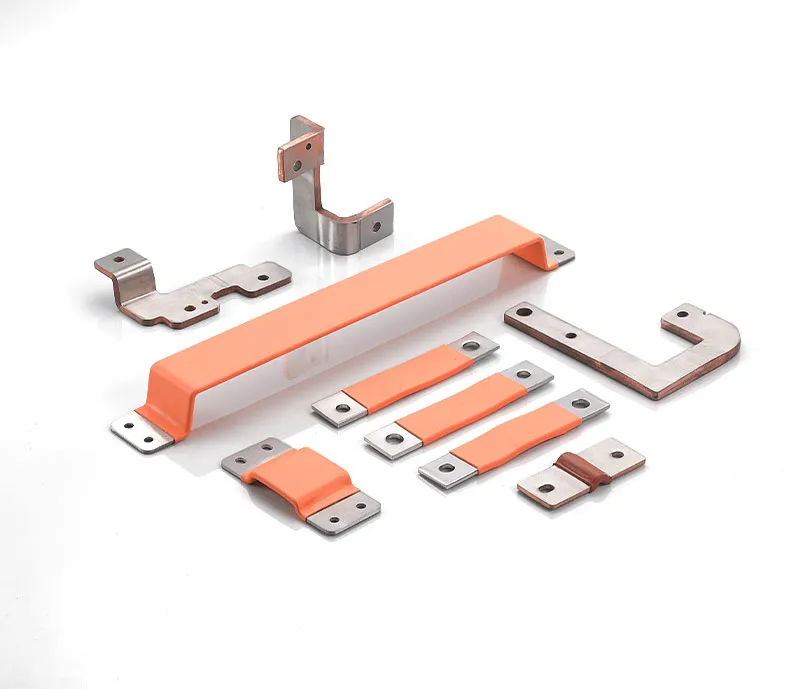

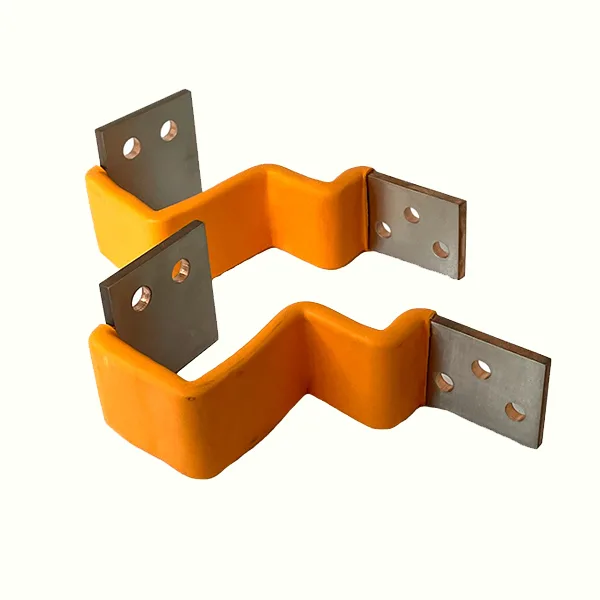

At JUMAI TECH, our rigid busbars are manufactured using precision stamping and deep-drawing technologies. This allows us to create complex geometries that are not just conductors, but structural elements of the electrical assembly. A rigid busbar is customized; it is engineered to fit a specific path, with precise bends and mounting holes that align perfectly with system components.

The Anatomy of Power Cables

Power cables consist of a central conductor (usually stranded copper or aluminum wire) surrounded by layers of insulation, shielding, and protective jacketing. The stranding allows for flexibility, enabling the cable to be routed through conduit or bent around corners during installation on-site.

While cables offer “off-the-shelf” convenience, this construction introduces inefficiencies. The insulation acts as a thermal blanket, trapping heat, while the circular cross-section offers the lowest possible surface-area-to-volume ratio, making heat dissipation difficult.

Thermal Management and Current Density

The most critical factor in power distribution is heat. Heat is the enemy of efficiency and the primary cause of component failure. In this arena, the rigid busbar is unequivocally superior.

Surface Area and Convection

The physics of cooling favors the flat geometry of a busbar. A rectangular rigid busbar has a significantly higher surface area compared to a round cable of the same cross-sectional area (CSA). This increased surface area facilitates natural convection and radiation, allowing the busbar to dissipate heat much faster.

Technical Note: According to the Copper Development Association, a flat copper busbar can carry significantly higher current densities than a round conductor of the same mass because the heat generated by the resistance is more easily rejected into the surrounding air.

When using power cables, engineers must often “derate” the cable ampacity, especially when cables are bundled together in trays. The insulation prevents airflow from reaching the conductor, leading to heat buildup. In contrast, rigid busbars are typically uninsulated or thinly coated, allowing direct thermal interaction with the environment.

The Skin Effect Advantage

In Alternating Current (AC) applications, the “Skin Effect” becomes a major factor. As frequency increases, current tends to flow along the outer surface (the “skin”) of the conductor rather than through the core.

- Cables: In a thick round cable, the center of the conductor carries very little current, resulting in wasted material and higher impedance.

- Busbars: A flat rigid busbar has a wide perimeter relative to its cross-section. This allows for better utilization of the conductor material in AC applications, reducing effective resistance and impedance.

Ampacity Comparison Table

The following table illustrates the comparative efficiency between a standard power cable and a copper rigid busbar at a typical temperature rise of 30°C.

| Feature | Round Power Cable (300mm²) | Rigid Copper Busbar (10mm x 30mm) |

| Cross-Section Area | ~300 mm² | 300 mm² |

| Shape | Circular | Rectangular |

| Insulation | Thick PVC/XLPE (Traps Heat) | Bare or Thin Epoxy (Radiates Heat) |

| Approx. Ampacity | ~550 Amps | ~750 – 800 Amps |

| Cooling Efficiency | Low | High |

| Current Density | Lower | Higher |

Data estimates based on standard ambient conditions. Specific performance depends on alloy and environment.

Space Optimization and System Footprint

In modern manufacturing, floor space is expensive. Whether it is inside a server rack or a factory floor, reducing the volume of electrical enclosures is a priority. This is where JUMAI TECH’s expertise in Precision Stamping Dies complements busbar technology to save space.

The Bend Radius Constraint

Power cables have a severe limitation known as “Minimum Bend Radius.” To prevent damage to the insulation and the conductor strands, a thick power cable typically requires a bend radius of 6 to 12 times its diameter.

- The Cable Problem: If you need to turn a 90-degree corner with a heavy-gauge cable, you might need 200mm or more of clearance. This forces enclosures to be significantly larger than the components they house just to accommodate the wire loops.

- The Busbar Solution: A rigid busbar can be bent at sharp 90-degree angles (using precision press brakes and stamping dies) with a near-zero bend radius relative to the clearance needed.

Reducing Switchgear Depth

By utilizing rigid busbars, engineers can reduce the depth of switchgear cabinets by up to 30%. The busbars can be stacked tightly using compact insulators, creating a dense “sandwich” of power distribution that cables simply cannot replicate.

This compactness is vital in industries like Automotive EV Manufacturing, where every millimeter inside a battery pack counts toward energy density and vehicle range.

Electrical Performance: Short Circuits and Impedance

Beyond heat and space, the electrical integrity of the system during fault conditions is paramount.

Short-Circuit Strength

When a short circuit occurs, massive electromagnetic forces are generated between conductors. These forces can cause cables to “whip” violently, potentially damaging connections or destroying the enclosure.

Rigid busbars, by definition, are rigid. When properly supported by high-strength insulators, they can withstand immense mechanical dynamic stresses during a fault event. At JUMAI TECH, we simulate these stresses during the design phase to ensure our custom copper busbars maintain structural integrity under peak fault currents (kA).

Low Inductance Design

For sensitive electronic equipment, such as in data centers or inverter drives, inductance is a critical parameter.

- Cable Inductance: The spacing between round cables is often irregular, and the circular geometry naturally creates higher inductance.

- Busbar Inductance: Flat rigid busbars can be mounted parallel to each other with very small separation distances. This parallel arrangement of wide, flat conductors significantly reduces the self-inductance of the circuit. Lower inductance results in cleaner power delivery and fewer voltage spikes, which is essential for the longevity of sensitive capacitors and semiconductors.

Installation, Assembly, and Human Error

The cost of a power distribution system is not just the material cost; it is the cost of installation, labor, and potential rework.

The Cost of “Cable Spaghetti”

Wiring a complex panel with heavy power cables is physically demanding and prone to error.

- Labor Intensity: Stripping, lugging, and crimping large cables requires hydraulic tools and significant manual effort.

- Torque Issues: Cable lugs can loosen over time due to thermal cycling and the “flow” of the stranded copper, leading to hot spots and potential fires.

- Tracing Difficulty: In a panel full of bundled cables, tracing a fault is a nightmare for maintenance personnel.

The Plug-and-Play Nature of Busbars

Rigid busbars designed by JUMAI TECH are essentially “pre-fabricated” connections.

- Precision Fit: Because we use Precision Stamping Dies and CNC bending, every busbar is identical. If it fits, it is correct. If it doesn’t fit, the operator knows immediately that something is wrong. This acts as a Poka-Yoke (mistake-proofing) mechanism.

- Faster Assembly: There is no stripping or crimping. Assembly involves bolting the busbar to the designated terminal. This can reduce assembly time by up to 50% compared to cabling.

- Aesthetics and Maintenance: A busbar system looks clean and organized. Infrared (thermal) inspections are easier because the conductors are visible and not hidden behind bundles of wire.

JUMAI TECH’s Approach: Customization and Material Science

At deepdrawtech.com, we don’t just sell standard copper bars; we provide engineered solutions. Understanding the material science behind the Rigid Busbar is part of our value proposition.

Material Selection: Copper vs. Aluminum

While aluminum is lighter and cheaper, copper remains the gold standard for high-performance rigid busbars.

- Conductivity: Copper has approximately 60% higher conductivity than aluminum. This means a copper busbar can be smaller than an aluminum one for the same current, saving critical space.

- Oxidation: Aluminum oxide acts as an insulator, which can cause connection failures if not properly treated. Copper oxide is conductive, making connections more reliable over time.

- Our Standard: JUMAI TECH primarily utilizes Oxygen-Free Copper (C10200) or Electrolytic Tough Pitch (ETP) Copper (C11000) to ensure maximum conductivity and ductility for complex deep-drawn and bent shapes.

Plating Technologies

To further enhance performance, rigid busbars are often plated.

- Tin Plating: Excellent for preventing corrosion and ensuring good contact with aluminum or copper terminals.

- Silver Plating: Used for the highest conductivity requirements and high-temperature applications, minimizing contact resistance at the joints.

- Nickel Plating: Ideal for harsh environments where extreme corrosion resistance is required.

Integration with Deep-Drawn Components

One of our unique capabilities at JUMAI TECH is integrating Deep-Drawn Components into the busbar assembly. For example, we can manufacture deep-drawn caps or shields that protect the busbar connection points, or create complex stamped brackets that serve as both a structural mount and a grounding path. This holistic approach to manufacturing ensures that your busbar isn’t just a conductor, but an integral part of your mechanical assembly.

Industry Applications: Where Rigid Busbar Wins

While cables are still suitable for long-distance runs or low-power residential wiring, rigid busbars have become the standard in several high-tech sectors.

1. Electric Vehicles (EV) and Hybrid Systems

The automotive industry is shifting aggressively toward rigid busbars for battery interconnects and inverter connections. The vibration resistance and high energy density of rigid busbars make them safer and more reliable than cables in a moving vehicle. The International Electrotechnical Commission (IEC) standards for EV safety increasingly favor the structural integrity of busbars.

2. Renewable Energy

Solar inverters and wind turbine nacelles handle massive currents. Rigid busbars are used here to minimize resistive losses. Every watt lost to resistance in a cable is a watt that cannot be sold to the grid. The efficiency of copper busbars directly impacts the ROI of renewable energy projects.

3. Data Centers

Modern data centers consume megawatts of power. Delivering this power to server racks via overhead busway systems allows for modularity. Servers can be added or removed without rewiring the entire room—something impossible with traditional pipe-and-wire methods.

4. Telecommunications

In telecom base stations (4G/5G), reliability is non-negotiable. Rigid busbars provide a low-impedance ground path, protecting sensitive equipment from lightning strikes and power surges.

Conclusion: Making the Strategic Choice

The debate between Rigid Busbar and power cables is ultimately a debate between long-term engineering efficiency and short-term familiarity. While cables may seem easier to procure initially, they often bring hidden costs in the form of space constraints, thermal management headaches, and higher installation labor.

A rigid busbar system offers a sleek, efficient, and robust solution that aligns with the demands of modern high-power technology. It maximizes current density, minimizes footprint, and provides a level of reliability that stranded cables simply cannot match.

At JUMAI TECH, we are more than just manufacturers; we are partners in your design process. With our deep expertise in Precision Copper Busbars, Deep-Drawn Components, and Precision Stamping Dies, we can help you transition from cumbersome cabling to streamlined busbar architectures. We understand that every micron matters, and our global customers rely on our precision to keep their power flowing safely and efficiently.

If you are ready to optimize your power distribution system, reduce your enclosure size, and improve thermal performance, it is time to consider the rigid busbar.

Contact JUMAI TECH today at www.deepdrawtech.com to discuss your custom specifications with our engineering team.