In the world of precision manufacturing, selecting the right production method is rarely a black-and-white decision. It is a calculated balance of engineering constraints, volume requirements, material properties, and ultimately, cost efficiency. At JUMAI TECH, we have spent years mastering the intricacies of Precision Copper Busbars, Precision Stamping Dies, and Deep-Drawn Components. We have stood on the factory floor, analyzing blueprints for complex cylindrical housings and seamless enclosures, facing the perennial question: Should this part be machined from a solid block, or is it a candidate for deep drawn metal stamping?

The answer often dictates the success of a product launch. While CNC machining offers incredible precision and flexibility for prototyping and low-volume runs, it hits a wall when scalability and material conservation become paramount. Conversely, deep drawn metal stamping is the silent giant of high-volume manufacturing, capable of transforming flat sheets into complex, seamless 3D shapes in mere seconds. This article serves as a comprehensive guide for engineers and procurement managers, dissecting the technical and economic warfare between these two manufacturing heavyweights.

Table of Contents

The Fundamental Differences: Forming vs. Subtractive Manufacturing

To understand the comparison, we must first strip these processes down to their physics. The fundamental difference lies in how they treat the raw material—specifically, whether they move the metal or remove it.

The Mechanics of CNC Machining

Machining is a “subtractive” process. You begin with a solid block or rod of material—be it aluminum, stainless steel, or copper—and use hard cutting tools to chip away everything that isn’t the final part. Whether using a 5-axis milling machine or a CNC lathe, the process relies on shear stress to remove material in the form of chips or swarf.

While machining allows for the creation of incredibly thick walls and non-uniform geometries that would be impossible to stamp, it is inherently wasteful. In many complex housing applications, up to 80% of the raw material is turned into scrap. Furthermore, the cycle time is dictated by the volume of material to be removed; a deep hollow part takes significantly longer to machine because the cutter must physically travel through all that empty space to clear it out.

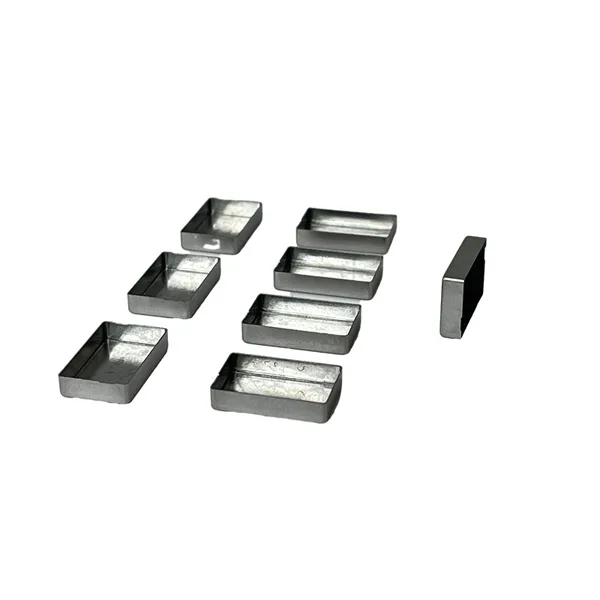

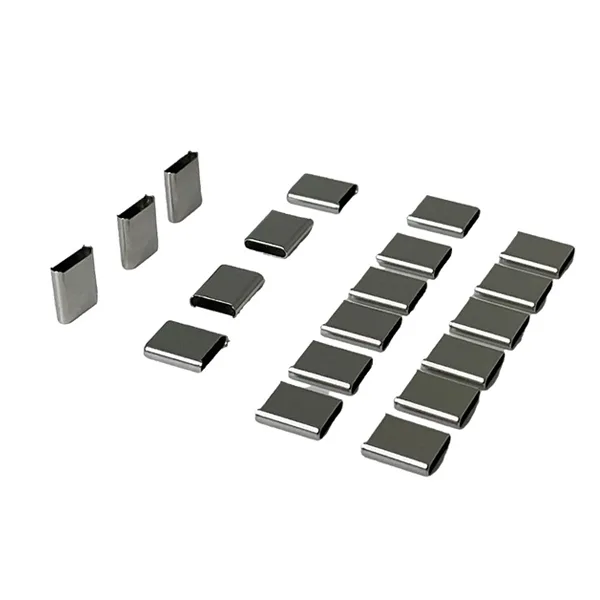

The Science of Deep Drawn Metal Stamping

In stark contrast, deep drawn metal stamping is a “forming” process. We start with a flat metal blank and force it into a die cavity using a punch. The metal is not cut away; it is plastically deformed. Under immense pressure, the material flows over the die radius, transforming from a flat disc into a cup, a can, or a complex seamless enclosure.

This process relies on the material’s ductility. As experts at JUMAI TECH, we know that successful deep drawing requires precise control over radial tension and tangential compression to prevent wrinkles or tears. Because we are rearranging the metal rather than destroying it, the material waste is minimal—usually limited only to the initial skeleton of the strip. For high-volume production of parts like battery cans, sensor housings, or motor sleeves, deep drawing is not just an alternative; it is the industry standard for efficiency.

Economic Analysis: The Volume Tipping Point

The most immediate factor in choosing between deep drawn metal stamping and machining is almost always economics. However, the cost structure of these two methods is diametrically opposite.

Understanding Tooling Amortization

Deep drawing requires hard tooling. This involves precision-machined punches, dies, and blank holders, often made from hardened tool steel or carbide. For complex multi-stage parts, this might require a Progressive Die or a Transfer Die setup. The upfront investment for this tooling can range from thousands to tens of thousands of dollars.

For a startup making 500 parts, this initial capital expenditure (CapEx) is difficult to justify. However, once the tooling is made, it can produce millions of parts with minimal maintenance. The cost per unit drops precipitously as the volume increases because the tooling cost is amortized over a larger number of units.

The CNC Cost Curve

Machining has virtually zero tooling cost in terms of molds or dies. You pay for the programming time (NRE) and standard cutting tools (end mills, drills), but you do not need to build a custom physical mold. This makes machining the undisputed king of prototyping and low-volume runs (1 to 1,000 parts).

However, machining has a high “variable cost.” The machine time remains constant per part. If it takes 10 minutes to machine a housing, it will always take 10 minutes, whether you make one or one million. There is no economy of scale in cycle time.

Comparative Cost Table

To illustrate this, let’s look at a hypothetical production run for a cylindrical copper housing, a common component we handle at JUMAI TECH for our busbar and electrical clients.

| Feature | CNC Machining | Deep Drawn Metal Stamping |

| Initial Tooling Cost | Low ($0 – $500 programming) | High ($5,000 – $50,000+) |

| Cycle Time Per Part | Minutes (e.g., 3-5 mins) | Seconds (e.g., 2-5 seconds) |

| Material Waste | High (40% – 80% scrap) | Low (10% – 20% scrap) |

| Cost Efficiency (100 parts) | High Efficiency | Low Efficiency |

| Cost Efficiency (100,000 parts) | Low Efficiency | High Efficiency |

| Labor Intensity | Moderate (Machine oversight) | Low (Automated presses) |

As the data suggests, the “tipping point”—where deep draw becomes cheaper than machining—usually sits between 3,000 and 5,000 units, depending on the complexity of the part.

Material Science: Grain Flow and Structural Integrity

One of the most overlooked advantages of deep drawn metal stamping is the metallurgical benefit it confers on the final product. As a specialist in manufacturing Precision Copper Busbars and components, I have seen firsthand how the manufacturing process alters the internal structure of the metal.

The Problem with Machined Grains

Metals have a grain structure, similar to the grain in wood. When a part is machined from a solid block, the cutting tool slices through these grains. By severing the grain flow, you introduce potential weak points in the material structure. This is particularly critical in fatigue-loading applications where the part is subject to vibration or cyclical stress. The exposed grain ends can become initiation sites for micro-cracks.

Work Hardening in Deep Drawing

Deep drawing, conversely, flows with the grain. The process elongates the grain structure to follow the contour of the part. This continuous grain flow results in a part that is structurally superior and more resistant to fatigue.

Furthermore, most metals, including the stainless steel and copper alloys we use at JUMAI TECH, undergo work hardening (or strain hardening) during plastic deformation. As the metal is stretched and compressed into the die, it becomes harder and stronger. According to data from ASM International, the tensile strength of certain stainless steels can increase significantly after cold working processes like deep drawing. This allows engineers to often use thinner starting materials to achieve the same strength as a thicker, machined part, leading to further weight and cost savings.

Complexity and Design Limitations

While deep drawn metal stamping is powerful, it obeys the laws of physics, specifically the limits of ductility. Not every shape that can be machined can be drawn. Understanding these limitations is vital for Design for Manufacturing (DFM).

The Aspect Ratio Constraint

The “draw ratio” is the relationship between the diameter of the punch and the diameter of the blank. Generally, a single draw operation cannot exceed a certain depth-to-diameter ratio (limiting draw ratio or LDR) without the material fracturing.

To achieve very deep parts (where the depth is greater than the diameter), we must use “redrawing” processes. This involves moving the part through a series of dies, gradually stepping down the diameter and increasing the depth. At JUMAI TECH, we utilize multi-station transfer presses to achieve high aspect ratios that single-stage presses cannot handle. Machining does not have this limitation; if you have a long enough drill bit or boring bar, you can machine a deep hole, though tool deflection becomes a concern.

Corner Radii and Draft Angles

Machining can create sharp internal corners (using broaching or EDM) and perfect 90-degree walls. Deep drawing generally requires a radius at the bottom of the cup and the flange. The material cannot flow over a sharp 90-degree corner without tearing; it needs a smooth radius to slide over the die entry.

Additionally, while machined parts can have perfectly vertical walls, deep drawn parts often benefit from a slight draft angle to help release the part from the punch, although straight walls are achievable with ironing processes. If your design strictly requires zero radii in internal corners, machining (or a secondary machining operation on a stamped part) might be required.

Material Utilization: The Sustainability Angle

In the modern manufacturing landscape, sustainability is no longer a buzzword; it is a metric. When we discuss deep drawn metal stamping, we are inherently discussing a “Near Net Shape” process.

The Scrap Factor

Imagine producing a thin-walled titanium housing. Titanium is expensive. If you machine this from a solid rod, you are paying for the entire volume of the rod, turning 90% of that expensive alloy into chips. While chips can be recycled, the recovery value is a fraction of the raw material cost.

In deep drawing, you purchase a sheet. You punch a disc. You form the disc. The only waste is the web of material left between the discs. For expensive materials like Copper (critical for our JUMAI TECH busbar clients) or Kovar, this material saving translates directly to the bottom line.

Seamless Integrity

Deep drawing produces seamless parts. There are no welds to fail, and no bolted joints to loosen. For applications involving fluids or gases—such as fuel rails, HVAC components, or hermetic seals—a seamless deep drawn vessel offers superior leak integrity compared to a fabricated or multi-part machined assembly.

JUMAI TECH: Bridging the Gap

At www.deepdrawtech.com, we understand that the choice between machining and stamping is nuanced. That is why JUMAI TECH offers a holistic approach. While we specialize in Precision Copper Busbars and Deep-Drawn Components, we also possess the capability to perform secondary machining operations.

The Hybrid Approach

Often, the best solution is a hybrid one. We might deep draw the basic shape of a complex enclosure to take advantage of the material savings and grain structure benefits. Then, we transfer the component to a CNC machining center to add precise features that cannot be stamped, such as side threads, O-ring grooves, or perfectly flat sealing surfaces.

This “Draw-then-Machine” strategy offers the best of both worlds:

- Low Material Cost: You aren’t machining from solid.

- High Precision: You get the tight tolerances of CNC where it counts.

- Scalability: The base forming process is fast.

Our Expertise in Tooling

The heart of any deep draw process is the die. Our team at JUMAI TECH designs and manufactures Precision Stamping Dies in-house. We simulate the metal flow using advanced FEA (Finite Element Analysis) software before we cut a single piece of steel. This allows us to predict thinning, potential tearing, and springback, ensuring that when we launch production, the parts meet your exact specifications.

Making the Right Choice for Your Project

The battle between deep drawn metal stamping and machining isn’t about which process is “better” in the abstract; it is about which is better for your specific constraints.

If you are in the prototyping phase, require extremely thick walls, or have a volume of under 1,000 units, machining is likely your safest path. However, if your project demands:

- Scalability into the tens or hundreds of thousands.

- Complex, hollow, seamless shapes.

- Superior material strength through work hardening.

- Significant reduction in raw material costs.

Then deep drawn metal stamping is the undisputed winner.

At JUMAI TECH, we are more than just a manufacturer; we are your technical partners. Whether you need complex copper busbars for an EV battery pack or precision deep-drawn sensor housings, we have the experience to guide you through the DFM process. We invite you to explore our capabilities further at www.deepdrawtech.com. Let us help you transform your blueprints into high-performance realities, optimizing both your budget and your product quality.

FAQ

What is deep drawn metal stamping?

Deep drawn metal stamping is a manufacturing process that shapes flat sheets of metal into complex 3D shapes. Instead of cutting away material, it uses a punch to push the metal into a die, allowing the metal to be reformed and minimizing waste.

How does machining differ from deep drawn stamping?

Machining is a subtractive process where material is cut away from a solid block to create a part. In contrast, deep drawn stamping is a forming process that changes the shape of the metal without losing much material, making it more efficient for large productions.

When should I choose deep drawn stamping over machining?

If you need a large number of parts, complex shapes, and want to save on material costs, deep drawn stamping is often the better choice. However, for low-volume production or very thick parts, machining might be more suitable.

What are the cost differences between these processes?

Deep drawn stamping requires more upfront investment in tooling but becomes much cheaper per part as production volume increases. Machining has lower initial costs but can be more expensive in high-volume scenarios due to its consistent cycle time.

What materials can be used in deep drawn stamping?

Deep drawn stamping can use various metals including aluminum, stainless steel, and copper. The choice of material often depends on the specific requirements of the part being produced.

Are there design limitations with deep drawn stamping?

Yes, deep drawn stamping has limitations such as depth-to-diameter ratios and required corner radii, which are not issues in machining. Understanding these constraints is important when designing parts.

What environmental benefits does deep drawn stamping offer?

Deep drawn stamping is considered more sustainable as it produces less waste compared to machining. It uses the material efficiently, meaning less scrap and lower costs for expensive metals.

Can I combine both processes in my project?

Yes! A hybrid approach is often beneficial. You can deep draw the main shape of a part for material savings and then use machining for any precise features, ensuring efficiency and high quality.

What is tooling amortization?

Tooling amortization refers to the way costs for tools and dies are spread over the number of parts produced. With deep drawn stamping, the higher initial tooling costs lower the cost per unit as production scales up.

How do I choose the right process for my part?

Consider factors like production volume, complexity of the design, material costs, and the required strength of the final product. Consulting with experts can help you make the best choice for your project.