Thin-gauge copper busbar parts are everywhere in modern electrification, from EV battery packs and inverters to switchgear, energy storage, and high-density power distribution modules. When the copper is thin, every detail becomes less forgiving: burr height matters more, flatness is harder to hold, and deformation can show up as assembly headaches downstream. That’s exactly why metal stamping dies remain the most reliable path to repeatable geometry, scalable output, and predictable cost for OEM programs that need both precision and volume.

At JUMAI TECH (DeepDrawTech), we build and run tooling strategies that combine practical die engineering with production thinking. We help customers turn thin copper strip into busbar parts that assemble cleanly, plate consistently, and carry current safely, without forcing costly secondary operations.

Table of Contents

Why Thin-Gauge Copper Busbars Are Growing in Demand

Lightweighting and Packaging Pressure

Design teams are constantly asked to reduce mass and shrink envelope size without sacrificing ampacity. Thin-gauge copper busbar parts help meet packaging targets while still leveraging copper’s high conductivity, which is one reason copper remains dominant in power distribution. For a credible overview of copper’s electrical performance and common alloys used in electrical applications, the Copper Development Association is a solid reference (Copper Development Association).

High-Volume Platforms Need Process Stability

EVs, energy storage systems, and consumer electrification aren’t “prototype businesses” anymore. Once a platform ramps, the supplier base is expected to deliver consistent parts every day, and that is where metal stamping dies provide repeatability that batch processes struggle to match.

Thin Copper Is Sensitive to Process Variation

As thickness drops, copper becomes more susceptible to distortion from clamping, punching forces, and handling. The manufacturing route must control burrs, edge quality, and flatness in a way that stays stable over long runs, not just in first-article samples.

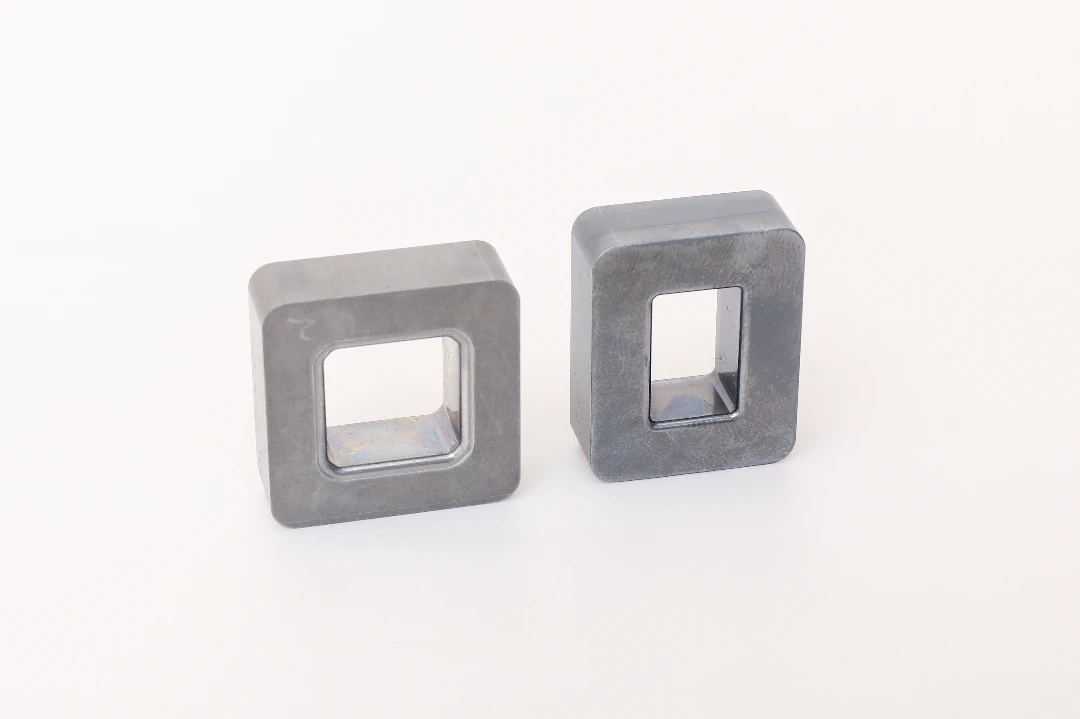

What “Metal Stamping Dies” Really Mean for Busbar Parts

A Stamping Die Is a System, Not Just a Tool

A stamping die is a controlled forming environment that guides strip material, holds it, cuts it, forms it, and ejects it in a repeatable sequence. For thin-gauge copper busbar parts, the die must also protect the strip from oil-can buckling, twist, and unwanted bending.

Key Outputs: Edge Quality, Flatness, and Hole Integrity

The best metal stamping dies for thin copper are designed around outcomes, not just features. Edge condition, burr direction, hole roundness, and the “real-world” flatness after plating and shipping often matter more than the nominal CAD.

How Dies Compare to Laser or Waterjet for Busbar Profiles

Laser cutting can be flexible for low-volume iteration, but it can introduce heat effects and slower unit economics at scale. Stamping dies shine when you need cycle-time efficiency, consistent features, and a controlled burr strategy across high volumes.

Thin-Gauge Copper Challenges That Drive Die Design Choices

Burr Control Is a Design Requirement, Not a QC Afterthought

Thin copper will “advertise” burr problems immediately during stacking, plating, insulation application, or lamination. Burr height targets must be defined early, and the die should be engineered so burr direction is consistent and manageable.

Distortion and Flatness Loss Are Common Failure Modes

Punching and forming forces can warp thin copper even when dimensional tolerances are met. A good die concept includes strip support, controlled forming stations, and handling steps that prevent cumulative distortion.

Copper Work-Hardening and Springback Affect Fit

Copper work-hardens as it is formed, and springback behavior can vary by alloy and temper. Managing this requires practical forming radii, adequate restrike plans, and realistic tolerance design tied to the final assembly method.

Choosing the Right Die Type for Thin-Gauge Copper Busbar Parts

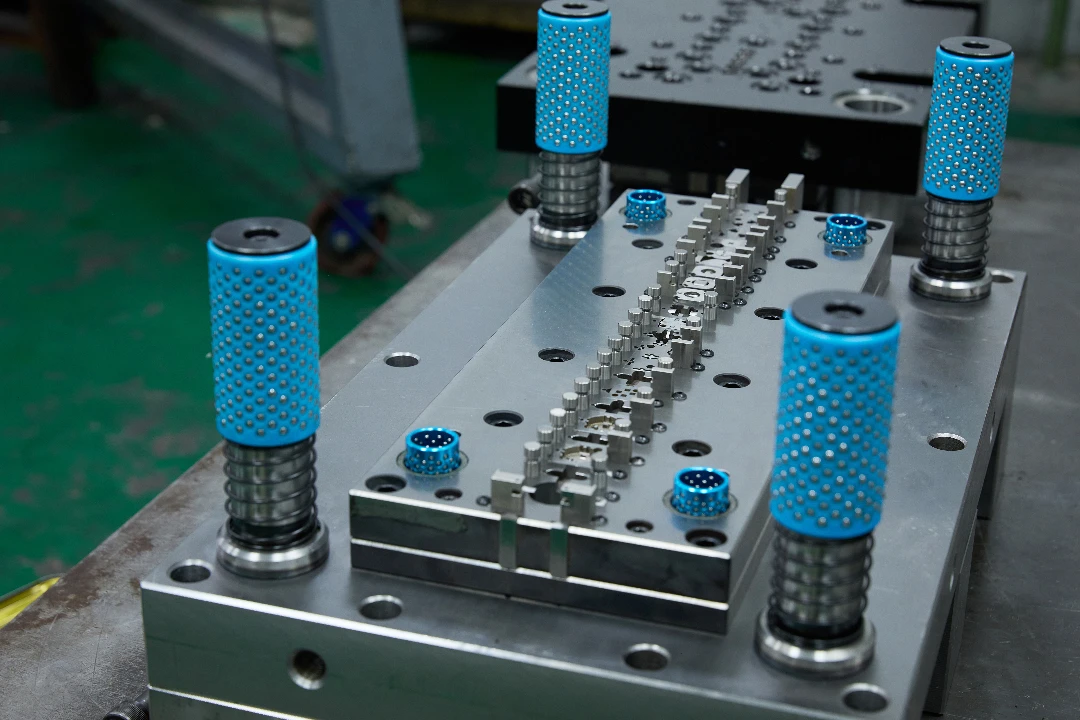

Progressive Dies for High-Volume, Multi-Feature Parts

Progressive metal stamping dies are often the best fit when the busbar requires multiple piercings, cutouts, and light forming features. Thin-gauge copper benefits from progressive sequencing because it allows controlled, step-by-step deformation instead of forcing everything in one hit.

Compound Dies for Simple, Flat Blanks

If the part is mostly a flat outline with holes, a compound die may be efficient. It can reduce complexity and speed up production, but it demands excellent strip control to avoid distortion during the single-stroke operation.

Transfer Dies for Larger Parts or Complex Forming

When parts are too large for practical progressive strip layout, or when forming is more complex, transfer dies become a strong option. Transfer can protect thin copper from strip tension effects, although it increases automation and handling requirements.

Copper Material and Temper: What the Die Must “Assume”

Alloy Selection Impacts Punching Force and Edge Condition

Electrical busbars commonly use high-conductivity grades such as C110 copper, but different alloys and tempers behave differently in stamping. Material choice influences punch wear, burr formation, and achievable bend radii, so die design should begin with a confirmed material spec.

Standards and Material Specs Matter for Program Stability

OEMs often reference recognized standards for copper and related test methods, and it helps align expectations early. When customers ask about standardized copper and general material frameworks, organizations like ASTM provide widely used references (ASTM International).

Thickness Variation Must Be Designed Into Strip Strategy

Thin-gauge stock can have coil-to-coil variability, and that affects clearance selection, punch penetration, and strip feeding behavior. The best approach is to plan for a realistic thickness band rather than assuming a single perfect number.

Core Design Rules for Metal Stamping Dies on Thin Copper

Clearance Strategy: The Foundation of Burr and Tool Life

Clearance is not just a textbook value; it’s a business decision balancing burr height, punch wear, and edge quality. In thin copper busbar parts, too-tight clearance can raise tooling stress and shorten life, while too-large clearance can create unacceptable burrs and tapered holes.

Strip Support and Guided Cutting Reduce Distortion

Thin copper needs support close to the cut to prevent deflection. Proper stripper design, guided punch entry, and stable lower support reduce edge roll and maintain hole quality over long production runs.

Radii, Reliefs, and Feature Spacing Protect the Strip

Sharp internal corners and tight feature spacing can trigger tearing, distortion, or accelerated wear. Practical radii and well-planned reliefs make parts more robust and make metal stamping dies easier to maintain.

Punching, Piercing, and Hole Quality in Thin-Gauge Busbar Parts

Hole Roundness and Positional Accuracy Affect Assembly Yield

Busbar hole patterns often interface with studs, rivets, or fasteners. If hole quality drifts, assembly becomes slow and inconsistent, so the die must control slug pulling, punch deflection, and strip walking.

Slug Control and Ejection Must Be Predictable

Thin copper slugs can stick, flip, or stack in ways that jam the die. A reliable design includes proper slug clearance, vacuum or air assist when needed, and surface treatments that reduce adhesion.

Burr Direction Planning Helps Downstream Processes

When a busbar will be laminated, insulated, or ultrasonically cleaned, burr direction and magnitude matter. Planning burr direction lets you control which face becomes the “functional” interface, reducing surprises during assembly.

Forming Features: Bends, Tabs, and Embosses on Thin Copper

Minimum Bend Radius and Crack Risk

Thin copper can still crack if the bend radius is too tight for the chosen temper. The die should be engineered around realistic bend radii and, when needed, include forming in stages rather than forcing an aggressive bend in a single station.

Springback Compensation and Restrike Stations

A restrike or calibration station can stabilize the final geometry. For thin copper busbar parts, this often improves flatness and angle consistency, especially when the assembly requires tight stack-up control.

Embossing and Coining for Contact Performance

Some busbars use coined or embossed areas to improve contact pressure, alignment, or welding interfaces. These features demand careful tonnage calculation and surface finish control to avoid introducing warpage in thin sections.

Tooling Materials, Coatings, and Surface Engineering

Tool Steel Choice Affects Wear and Edge Condition

Copper can be abrasive in unexpected ways, and it can also promote galling under certain conditions. Choosing the right tool steel, heat treatment strategy, and surface finish is a big lever for die uptime.

Coatings Reduce Galling and Stabilize Long Runs

Coatings can reduce adhesive wear and help maintain edge quality over production cycles. Even with a good coating, lubrication strategy must be consistent to prevent variability that shows up as burr growth or scratch marks.

Polishing and Surface Finish Influence Part Cosmetics

Busbar parts often remain visible or are plated, so surface marks matter. A die designed for thin copper should protect surface finish through controlled contact areas and optimized stripper pressure.

Press Selection and Process Windows for Thin Copper Stamping

Tonnage Is Not the Only Metric

Many problems happen even when a press has enough tonnage. For thin-gauge copper, rigidity, slide guidance, shut height consistency, and stroke behavior often matter more than the nameplate rating.

Speed, Feed, and Dwell Time Affect Heat and Stability

Running too fast can increase heat and reduce lubrication effectiveness, which accelerates wear. Running too slow can reduce throughput and raise unit cost, so the right window is about stable quality at the target output.

Monitoring and Control Improve Predictability

Sensors for misfeed detection, tonnage monitoring, and strip position can prevent expensive tool damage. A production-minded approach to metal stamping dies treats monitoring as part of the process, not an optional add-on.

Quality Control: How to Prove Busbar Parts Are “Right”

Dimensional Inspection That Matches Real Assembly Needs

A busbar can pass a drawing and still fail in the product if flatness or edge condition causes stacking issues. That’s why inspection plans should include flatness checks, burr audits, and functional gauge strategies when appropriate.

Process Capability and Repeatability Expectations

OEM programs often expect capability evidence over time. Building a stable process around a die allows you to demonstrate repeatability in a way that builds trust and reduces incoming inspection burden.

Quality Systems and Traceability

When customers require formal quality frameworks, ISO references provide a shared language for process control. Many buyers recognize ISO 9001 as a baseline quality management system standard (ISO 9001 Overview).

Cost Drivers and Lead Time in Metal Stamping Dies for Thin Copper

Complexity, Stations, and Tolerance Drive Tooling Cost

More stations, tighter tolerances, and higher cosmetic requirements increase tooling investment. The advantage is that once the die is stable, the unit economics can be excellent for ongoing production.

Tool Life and Maintenance Strategy Affect Total Cost of Ownership

A cheaper die that requires frequent repair is usually more expensive over the program life. The best metal stamping dies are designed for maintainability, predictable wear points, and planned service intervals.

Prototyping and Bridge Production Reduce Risk

For new programs, bridge strategies can shorten launch timelines. Rapid prototypes, pilot tools, or low-cavity solutions can validate geometry and assembly behavior before full production tooling is finalized.

DFM Checklist for Thin-Gauge Copper Busbar Parts

Design for Manufacturability Reduces Surprises

DFM is how you prevent rework loops and avoid “it worked in CAD” failures. For thin copper, DFM should address burr direction, minimum feature spacing, bend radii, and flatness targets tied to the assembly method.

Think About Plating and Insulation Early

If the busbar will be plated, laminated, or overmolded, those processes impose additional constraints. Edge quality, cleanliness, and surface finish requirements should be part of the stamping die conversation from day one.

Documentation and Standardization Improve Ramp-Up

Clear drawings, GD&T aligned to function, and consistent material specs reduce interpretation risk. In high-volume programs, fewer ambiguities mean fewer production interruptions.

Why JUMAI TECH for Metal Stamping Dies and Thin Copper Busbar Parts

Tooling + Production Mindset, Not “Tooling Only”

Some suppliers build dies; others build parts; the best outcomes happen when tooling is developed with production reality in mind. At JUMAI TECH, we approach metal stamping dies as part of an integrated manufacturing system, aiming for stable output, easy maintenance, and consistent quality.

Engineering Support That Speaks OEM Language

We collaborate on strip layout, tolerance rationalization, and process selection so the final part is easier to assemble and easier to scale. When needed, we also align inspection and capability expectations so the approval process moves faster.

Reliable Delivery for Global Programs

Thin-gauge copper busbar parts are usually not “nice-to-have” components; they’re mission-critical for power delivery. Our goal is to deliver predictable quality and program stability, so your assembly lines don’t absorb hidden variation.

Start Your Thin-Gauge Busbar Tooling Project with a Clear Plan

What to Share for a Fast, Accurate Quote

Provide your drawing, target volume, material spec (alloy + temper), thickness range, and any special requirements like plating, insulation, or cosmetic constraints. The more the die designer knows about downstream assembly, the better the die concept will be.

What You Can Expect From a Professional Die Proposal

A strong proposal should explain die type choice, key risks, inspection strategy, and maintenance assumptions. It should also clarify what will be controlled in-die versus what may require secondary operations.

Let’s Build a Stable, Scalable Stamping Solution

If you are sourcing metal stamping dies for thin-gauge copper busbar parts, JUMAI TECH can help you move from concept to repeatable production with less trial-and-error. Send your RFQ package and we’ll recommend the most practical tooling and process path for your program.