The manufacturing world is currently undergoing a radical transformation, driven by a singular, relentless demand: make it smaller, make it lighter, and make it more powerful. From the pocket-sized supercomputers we call smartphones to the microscopic surgical implants saving lives daily, the trend toward miniaturization is reshaping every industrial vertical. However, as components shrink to the sub-millimeter scale, the margin for error effectively vanishes. This is where the advanced capabilities of precision die and stamping become not just a manufacturing option, but an engineering necessity.

At JUMAI TECH, we have spent years mastering the intricate dance between raw material and high-tonnage force. We understand that producing a standard bracket is vastly different from manufacturing a micro-connector or a miniature deep-drawn shield where tolerances are measured in single-digit microns. This article explores the technical nuances, material challenges, and tooling innovations that allow precision die and stamping to serve as the backbone of the modern miniaturization revolution.

Table of Contents

The Evolution of Manufacturing: The Drive for Micro-Scale Precision

The historical trajectory of manufacturing has always leaned toward efficiency, but the modern era demands efficiency within increasingly microscopic footprints. The concept of “smaller” is no longer just about aesthetics; it is about performance density. In the automotive sector, specifically in Electric Vehicles (EVs), engineers are trying to pack more battery cells into confined spaces, requiring ultra-thin, highly conductive precision copper busbars. In the medical field, less invasive surgeries require tools and sensor housings that are barely visible to the naked eye.

The Limits of Traditional Machining

Historically, CNC machining was the go-to for high-precision parts. However, as volume demands skyrocketed—millions of units for smartphone components or automotive sensors—machining became too slow and costly per unit. Traditional stamping was faster but lacked the accuracy required for micro-features. This gap in the market gave rise to modern precision die and stamping. By integrating advanced metallurgy with computer-controlled press systems, we can now achieve production speeds of hundreds of strokes per minute while maintaining tolerances that rival the best Swiss machining.

The Economic Case for Precision Stamping

For Global B2B procurement managers, the shift to precision stamping for miniaturized parts is often a financial decision as much as a technical one. Stamping is inherently scalable. Once the progressive die is engineered and validated, the cost per unit drops significantly compared to laser cutting or wire EDM (Electrical Discharge Machining). For high-volume production of deep-drawn components or complex terminals, precision die and stamping offers the only viable path to economic feasibility without sacrificing the geometric integrity of the part.

The Core Mechanics of Precision Die and Stamping

To understand how we achieve miniaturization, one must first grasp the definition of precision die and stamping in this context. It is not merely “stamping with care.” It involves a holistic engineering approach that accounts for the dynamic behavior of the press, the thermal expansion of the die, and the molecular flow of the material. When stamping parts that are smaller than a grain of rice, factors that are negligible in macro-stamping—such as air resistance on the falling part or the viscosity of the lubricant—become critical design constraints.

Controlling the Force Distribution

In micro-stamping, the force required to shear or form the metal is relatively low, but the precision with which that force is applied must be absolute. Standard presses often suffer from “ram tilt” or deflection, which is acceptable for large brackets but catastrophic for micro-contacts. At JUMAI TECH, our precision die and stamping equipment utilizes high-rigidity frames and advanced guiding systems. This ensures that the punch meets the die with perfect perpendicularity, preserving the delicate features of the miniaturized component and extending the life of the expensive tooling.

The Importance of Clearance Management

The clearance between the punch and the die determines the quality of the sheared edge. In standard stamping, clearance might be 10% of the material thickness. However, when stamping foil-thin materials (e.g., 0.05mm thick stainless steel or copper alloys), the clearance must be maintained at sub-micron levels. If the clearance is too large, the material creates a burr; if it is too tight, the tooling wears out instantly. Achieving this requires precision die and stamping techniques that rely on wire EDM cutting technologies capable of holding tolerances within +/- 0.002mm.

| Feature | Standard Stamping | Precision Micro-Stamping |

| Material Thickness | > 0.5mm | 0.02mm – 0.5mm |

| Tolerance Range | +/- 0.1mm | +/- 0.005mm to +/- 0.01mm |

| Production Speed | 40-100 SPM (Strokes Per Minute) | 200-1000+ SPM |

| Tooling Clearance | 5-10% of stock thickness | < 5% of stock thickness |

| Primary Challenge | Material Handling | Tooling Deflection & Statics |

Material Science in Miniaturized Components

When you shrink a component, you cannot simply shrink the material properties. The physics of metallurgy change as you approach the grain size of the metal. For precision copper busbars and deep-drawn sensor housings, understanding these material behaviors is the difference between a functional part and a pile of scrap.

Grain Structure and Formability

In macro-sized parts, the metal acts as a homogeneous continuum. In miniaturized parts, particularly those produced via precision die and stamping, the feature size might be approaching the size of the individual metal grains. If a narrow connector leg is only three grains wide, the mechanical properties become unpredictable, leading to cracking or inconsistent spring rates. JUMAI TECH works closely with global material suppliers to source fine-grain alloys specifically designed for micro-stamping. This ensures consistent formability and electrical conductivity, which is vital for high-performance electronics.

The Challenge of Springback

Springback—the tendency of metal to return to its original shape after bending—is notoriously difficult to predict in small parts. In miniaturized precision stamping, a variation of 0.5 degrees in a bend angle can prevent a connector from mating correctly. Because the material is so thin, it is highly sensitive to rolling direction and variations in tensile strength. Our engineering team utilizes advanced Finite Element Analysis (FEA) simulation software (referenced by organizations like ASM International) to predict springback before we even cut the steel for the die. This allows us to engineer “over-bend” features into the precision die and stamping tool to compensate naturally.

Deep-Drawn Components: The Art of Miniature Containment

One of JUMAI TECH’s core competencies lies in Deep-Drawn Components. Deep drawing is a process where a sheet metal blank is drawn into a forming die by a mechanical punch. Doing this at a micro-scale—creating tiny cans, caps, and housings—presents unique challenges that standard stamping houses often fail to address.

Managing Aspect Ratios in Micro-Drawing

The “aspect ratio” is the relationship between the length of the drawn part and its diameter. As parts get smaller, achieving a high aspect ratio (a long, thin tube) becomes exponentially more difficult due to the risk of tearing the material. Successful micro-deep drawing requires a multi-station progressive die where the material is drawn in small, calculated increments. Through our specialized precision die and stamping processes, we can achieve draw ratios that allow for the production of complex, seamless enclosures used in fiber optic components and medical fluid management systems.

Lubrication and Surface Tension

In standard deep drawing, heavy lubricants are used to reduce friction. However, in miniaturized parts, the surface tension of a thick lubricant can actually deform the part or cause it to stick to the punch (a phenomenon known as “slug pulling”). We employ specialized, low-viscosity, evaporative lubricants that provide the necessary film strength for the drawing process but vanish without leaving residues that could interfere with downstream plating or assembly. This attention to chemical detail is a hallmark of high-quality precision die and stamping.

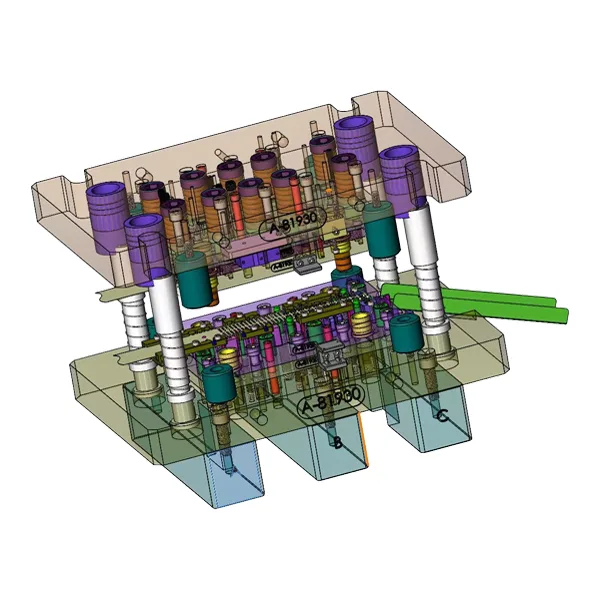

Tooling: The DNA of Precision

The old adage “you are only as good as your tools” is the absolute truth in our industry. The die is the heart of the operation. For miniaturized parts, the Progressive Die—a series of stations that perform operations as the strip moves through the press—must be a masterpiece of engineering.

Carbide Tooling for Longevity

Standard tool steel often fails under the rigors of cutting abrasive materials like phosphor bronze or stainless steel at high speeds. For our precision die and stamping operations, JUMAI TECH utilizes Tungsten Carbide for active punch and die components. Carbide is incredibly hard and wear-resistant, allowing us to run millions of cycles with minimal maintenance. This stability is crucial; when your tolerance is +/- 0.005mm, even microscopic tool wear results in out-of-spec parts.

Modular Die Design for Maintenance

Miniature dies are fragile. If a punch breaks, you cannot afford to take the entire tool offline for days. We utilize a modular insert design in our precision die and stamping tooling. This allows our technicians to swap out individual stations or punches rapidly without removing the entire die base from the press. This design philosophy ensures continuity of supply for our clients, reducing lead times and ensuring that just-in-time delivery schedules are met, regardless of the complexity of the miniaturized component.

Strategic Applications in Global Industries

The capabilities of precision die and stamping are fueling innovation across several high-value sectors. At JUMAI TECH, we see diverse applications where our precision parts serve as critical infrastructure.

1. Medical Device Manufacturing

The trend toward minimally invasive surgery requires tools that are small, strong, and biocompatible. We manufacture titanium and stainless steel components for surgical staplers, hearing aid contacts, and insulin pump internals. In this sector, there is zero room for failure. A burr on a stamped part could cause tissue damage or device failure. Our precision die and stamping process includes automated optical inspection to ensure 100% compliance with strict medical standards (ISO 13485).

2. Automotive and E-Mobility

While cars are large, their brains are small. The modern EV relies on thousands of sensors, relays, and control units. We specialize in manufacturing Precision Copper Busbars and interconnects that handle high currents within compact spaces. These parts must withstand thermal cycling and vibration. Our precision stamping ensures that the contact surfaces are perfectly flat to maximize electrical efficiency, a critical factor in extending EV range.

3. Telecommunications and 5G

The rollout of 5G technology demands higher frequency transmission, which requires shielding components to prevent electromagnetic interference (EMI). JUMAI TECH produces millions of deep-drawn EMI shields. These tiny metal “cans” fit over chips on a circuit board. Through precision die and stamping, we ensure that these shields have perfect planarity for surface mounting (SMT), ensuring high-speed automated assembly for our telecom clients.

Addressing the Challenges of Handling and Packaging

One of the most overlooked aspects of manufacturing miniaturized parts is: How do you hold them? A part that weighs 0.05 grams can be blown away by a gentle breeze or crushed by the weight of a standard shipping container.

Reel-to-Reel Processing

To mitigate handling issues, JUMAI TECH advocates for reel-to-reel stamping. Instead of separating the parts completely, they are left attached to a carrier strip. This allows the parts to be wound onto a reel, similar to a roll of film. This method is essential for customers who use automated assembly lines. The precision die and stamping process creates the part, and the reel protects the delicate features during shipping. The customer’s machines can then feed the reel and detach the parts immediately before assembly.

Cleanliness and Contamination Control

Micro-parts are highly susceptible to particulate contamination. A single speck of dust can insulate a micro-contact. Our production floor enforces strict cleanliness protocols. We utilize ultrasonic cleaning systems inline with our precision die and stamping operations to remove oil and particulates. For sensitive electronics, we offer cleanroom-packaging options to ensure that the parts arrive at the customer’s facility in pristine condition, ready for bonding or soldering.

Quality Control: Measuring the Invisible

You cannot manufacture what you cannot measure. Traditional calipers and micrometers are useless for parts that deform under the slightest contact pressure. JUMAI TECH has invested heavily in non-contact metrology.

Vision Systems and Optical Comparators

We employ high-resolution vision systems that use cameras and advanced software to measure part dimensions. These systems can detect deviations as small as 1 micron. By integrating these systems directly into the precision die and stamping production line, we can perform real-time statistical process control (SPC). If the trend lines show the dimensions drifting toward the tolerance limit (perhaps due to thermal expansion as the press warms up), the system alerts the operator to adjust before a bad part is ever made.

Material Verification

For components like Precision Copper Busbars, the alloy composition is critical. We utilize X-Ray Fluorescence (XRF) analyzers to verify the chemical composition of raw materials upon arrival. This ensures that the material entering our precision die and stamping workflow meets the exact conductivity and mechanical specifications required by our clients. This traceability is part of our commitment to ISO 9001 standards.

Why Partner with JUMAI TECH?

In the crowded landscape of global manufacturing, finding a partner who truly understands the intricacies of precision die and stamping for miniaturized parts is rare. Many shops claim to do “precision” work, but few have the dedicated infrastructure, the metallurgical expertise, and the deep-drawing heritage that JUMAI TECH possesses.

We are not just a supplier; we are a solution provider. Whether you are in the design phase of a complex micro-sensor or looking to scale production of a high-efficiency copper busbar, our team is equipped to guide you from prototype to mass production. We leverage our expertise in Deep-Drawn Components, Precision Stamping Dies, and accessories to help you navigate the complexities of miniaturization.

Your Next Step

The future is smaller, faster, and more precise. Don’t let manufacturing limitations hold back your product innovation. If you are developing components that require the highest levels of accuracy and reliability, it is time to engage with experts who speak the language of microns.

Contact JUMAI TECH today. Let us review your designs and demonstrate how our advanced precision die and stamping capabilities can turn your miniaturized concepts into tangible, high-performance realities. Visit us at www.deepdrawtech.com to request a quote or consult with our engineering team.