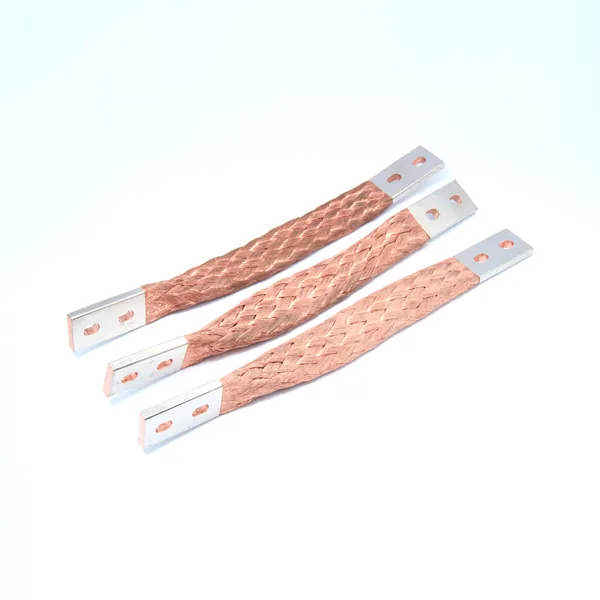

In the world of electrical power distribution and electronic engineering, the integrity of your connection points is just as critical as the power source itself. As the Editor of JUMAI TECH, and having spent years on the factory floor overseeing the production of custom Busbar Copper, deep-drawn components, and precision stamping dies, I have seen firsthand how environmental factors can ravage a poorly protected system. Copper is the gold standard for conductivity—second only to silver—but it has an Achilles’ heel: its susceptibility to oxidation and corrosion.

At JUMAI TECH (www.deepdrawtech.com), we understand that manufacturing a precision copper busbar is only half the battle. Ensuring that busbar performs reliably for twenty or thirty years in a harsh industrial environment, a humid offshore wind turbine, or the high-thermal cycle of an Electric Vehicle (EV) battery pack is the ultimate goal. This guide dives deep into the science of surface finishing, exploring why Busbar Copper plating is not just a cosmetic choice, but a fundamental engineering requirement for safety, efficiency, and longevity.

Table of Contents

The Critical Role of Surface Treatments for Busbar Copper

When we machine Busbar Copper at JUMAI TECH, fresh off our precision stamping dies, it features a brilliant, reddish-orange metallic luster. However, if left exposed to the atmosphere, this surface is chemically active. The primary reason for plating copper busbars is to ensure stable contact resistance over the component’s lifetime.

Combatting the Oxide Layer

Bare copper reacts with oxygen to form copper oxide. Initially, this might appear as a slight darkening of the metal, but chemically, it creates a high-resistance barrier. In high-power applications, increased resistance at the joint leads to localized heating. This heat accelerates further oxidation, creating a “thermal runaway” cycle that can lead to catastrophic failure or electrical fires.

According to data from the Copper Development Association (CDA), the formation of oxides significantly degrades the conductivity of the joint interface. While the bulk material remains conductive, the surface—where the actual power transfer happens—becomes an insulator. Plating provides a sacrificial or inert barrier that prevents this reaction.

Managing Contact Resistance

Contact resistance is a function of the surface area and the specific resistivity of the materials touching. However, no surface is perfectly flat. On a microscopic level, two mating busbars touch only at “asperities” (microscopic peaks). Plating materials like tin or silver are often softer than the base copper, allowing these asperities to deform under torque, increasing the effective contact area and reducing resistance. This is a critical factor we consider when designing Precision Stamping Dies for busbar assemblies—calculating not just the shape, but the mating surface interaction.

Tin Plating: The Industry Standard for Versatility

Tin is arguably the most common plating material used for Busbar Copper globally. It offers an excellent balance between cost, conductivity, and corrosion protection. At JUMAI TECH, a significant portion of the busbars we export for switchgear and industrial panels utilize tin plating.

Bright Tin vs. Matte Tin Finishes

There is a distinct technical difference between bright and matte tin, and choosing the wrong one can impact downstream manufacturing.

- Bright Tin: This finish has a mirror-like appearance due to organic additives in the plating bath that refine the grain structure. It is aesthetically pleasing and has a lower coefficient of friction, which is beneficial for connector pins that undergo repeated insertion. However, bright tin can be more brittle due to high internal stress.

- Matte Tin: This finish appears dull or whitish. It is generally free of brighteners, resulting in a deposit with lower internal stress. For Busbar Copper that requires post-plate forming or bending, matte tin is often preferred because it is less likely to crack at the bend radius. Furthermore, matte tin holds lubricants better, which can be advantageous in certain bolted connections.

The Phenomenon of Fretting Corrosion

One of the specific challenges with tin is “fretting.” This occurs when micro-movements (caused by thermal expansion or vibration) happen between two contact surfaces. These movements wear away the oxide layer, exposing fresh tin, which then oxidizes again. Over time, this debris builds up, increasing resistance.

To mitigate this, we recommend adhering to specific contact pressure standards. For tin-plated copper busbars, a higher contact pressure is generally required compared to silver to break through the harder tin oxide layer and maintain a gas-tight seal.

Tin Whiskers and Mitigation

In the electronics sector, “tin whiskers”—microscopic conductive filaments that grow from pure tin surfaces—are a known risk that can cause short circuits. While less of a concern for massive power busbars, it is critical for tight-pitch components. At JUMAI TECH, we often utilize tin alloys with small percentages of lead (where RoHS compliance permits) or specific annealing processes to mitigate whisker growth, ensuring the reliability of your deep-drawn components and busbars.

Silver Plating: The Premium Choice for High Efficiency

When maximum conductivity and performance are non-negotiable, silver is the plating of choice. Silver is unique because its oxide (silver oxide) is structurally soft and conductive. This means that even if a silver-plated Busbar Copper oxidizes, the connection remains electrically sound, unlike copper or tin oxides which are insulators.

Conductivity and Thermal Performance

Silver has the highest electrical and thermal conductivity of any metal. For applications like Electric Vehicles (EVs) or high-voltage substations, silver plating allows the busbar to run cooler. This efficiency can sometimes allow engineers to downsize the cross-section of the copper bar, saving weight and material cost—a strategy we often assist clients with during the prototyping phase of their Precision Copper Busbars.

Comparative Conductivity Table:

| Material | Electrical Conductivity (% IACS) | Thermal Conductivity (W/m·K) | Contact Resistance | Cost Factor |

| Copper (Oxygen-Free) | 101% | 390 | Low | Base |

| Silver | 105% | 429 | Very Low | High |

| Tin | 15% | 67 | Medium | Low |

| Nickel | 22% | 91 | High | Medium |

| Gold | 73% | 318 | Low | Very High |

Data Source: Reference values based on ASTM B193 Standards.

Managing Silver Sulfide (Tarnishing)

The primary drawback of silver is its reaction with sulfur in the atmosphere, creating silver sulfide (the black tarnish seen on silverware). While silver oxide is conductive, silver sulfide is semiconductive and can increase resistance slightly. However, in high-voltage switchgear, the “wiping action” of the switch mechanism is usually sufficient to clean the contact surface. For static bolted connections, the high conductivity of silver generally outweighs the tarnishing concern.

Applications Demanding Silver

At JUMAI TECH, we strongly recommend silver plating for:

- Mobile Machinery: Where vibration is constant. Silver is harder than tin and resists fretting corrosion better.

- High-Temperature Environments: Silver can withstand operating temperatures up to 200°C, whereas tin may begin to soften and lose mechanical integrity above 100°C.

- EV Battery Interconnects: Where every millivolt of drop counts against the vehicle’s range.

Nickel Plating: Durability and Barrier Protection

Nickel is rarely used as a standalone contact material for high-current Busbar Copper because of its relatively poor conductivity (only about 22% IACS) and hardness, which results in high contact resistance. However, it plays a vital support role in the plating ecosystem.

Nickel as a Diffusion Barrier

One of the most critical technical functions of nickel is acting as an underplate. When copper is plated directly with gold or tin, the copper atoms can eventually migrate (diffuse) through the plating layer to the surface, especially at elevated temperatures. This copper diffusion leads to surface oxidation and failure of the top layer.

By applying a layer of Nickel sulfamate or bright nickel between the Busbar Copper and the final finish, we create an impenetrable barrier that stops this migration. This is standard practice for high-reliability components produced at JUMAI TECH.

Corrosion Resistance in Harsh Environments

Nickel is extremely resistant to chemical attack. For Busbar Copper used in chemical plants, marine environments, or areas with high concentrations of ammonia or acids, a thick nickel outer layer may be used despite the conductivity penalty. In these cases, the design must account for the higher contact resistance, often by increasing the surface area of the joint.

Specialized Plating: Gold and Emerging Technologies

For specific electronic applications or extremely corrosive environments, standard tin or silver may not suffice.

Flash Gold and ENIG

Gold offers the ultimate corrosion resistance—it does not oxidize. However, due to cost, it is usually applied as a “flash” (very thin layer) over a nickel underplate. This is common in the Deep-Drawn Components we manufacture for signal transmission or low-voltage control sensors attached to the main power bus.

Electroless Nickel Immersion Gold (ENIG) is a process that deposits a uniform coating, which is crucial for complex shapes where electrolytic plating might result in uneven thickness due to current density variations.

Environmental Considerations and RoHS

The global push for environmentally friendly manufacturing affects plating choices. Traditional cadmium plating (once popular for corrosion) is largely banned. At JUMAI TECH, we strictly adhere to RoHS (Restriction of Hazardous Substances) directives. We utilize lead-free tin formulations and trivalent chromate passivation processes to ensure our Precision Copper Busbars meet the regulatory standards of the European and North American markets.

Selecting the Right Finish: A Decision Matrix

Choosing the right plating for your Busbar Copper involves balancing cost, electrical performance, and environmental conditions. Over my years in this industry, I have developed a simplified decision matrix to help our clients navigate these choices.

Busbar Plating Selection Guide:

| Feature / Requirement | Recommended Plating | Why? |

| Standard Indoor Switchgear | Tin | Cost-effective; adequate protection for climate-controlled areas. |

| High Current / High Voltage | Silver | Maximizes conductivity; reduces thermal rise at joints. |

| High Temperature (>100°C) | Silver or Nickel | Tin risks softening/melting; Silver remains stable. |

| Chemical/Marine Environment | Nickel (thick) or Gold | Resists salt spray and acidic atmospheres significantly better. |

| Aluminum-to-Copper Joining | Tin | Mitigates galvanic corrosion between dissimilar metals (Al and Cu). |

| Electronic Connectors | Gold over Nickel | Ensures signal integrity and withstands low-force cycles. |

The Importance of Layer Thickness

It is not enough to simply specify “Tin Plating.” The thickness determines the lifespan.

- Standard Commercial: 3 to 5 microns (µm).

- Heavy Duty / Outdoor: 8 to 12 microns (µm).

- Extreme Service: >20 microns (µm) or specific alloy layering.

We use X-Ray Fluorescence (XRF) technology at our JUMAI TECH quality lab to verify that every batch of Busbar Copper meets the exact thickness specified by the client. An insufficient layer leads to premature pitting, while an excessively thick layer can cause cracking during assembly.

The Manufacturing Process at JUMAI TECH

Understanding the “how” gives you confidence in the “what.” At JUMAI TECH, our process for treating Busbar Copper is rigorous and integrated into our precision manufacturing workflow.

1. Surface Preparation (The Most Critical Step)

The best plating bath in the world will fail if the substrate is dirty. Before plating, our stamped or machined busbars undergo a multi-stage cleaning process:

- Degreasing: Removing oils and lubricants from the stamping dies.

- Pickling: Using mild acids to remove existing heavy oxides.

- Activation: Preparing the copper surface structure to accept the bond of the plating metal.

2. Electrolytic vs. Electroless Plating

- Electrolytic Plating: We use electrical current to deposit the metal. This is fast and efficient for standard busbars. We carefully control current density to prevent “dog-boning” (where plating is thicker at the edges and thinner in the center).

- Electroless Plating: This is a chemical deposition process without electricity. We use this for complex Deep-Drawn Components or hollow parts where internal surfaces need coating, as electrolytic methods struggle to plate inside deep recesses (the Faraday Cage effect).

3. Precision Stamping Integration

One of JUMAI TECH’s unique advantages is that we design the Precision Stamping Dies in-house. We can design dies that account for the post-plating dimension changes. If a part requires a tight tolerance of +/- 0.05mm, adding 10 microns of plating matters. We adjust our tooling dimensions to ensure the final plated part fits perfectly in your assembly.

4. Quality Control and Salt Spray Testing

To prove the corrosion resistance of our Busbar Copper, we utilize Salt Spray Testing (ASTM B117).

- Tin: typically survives 24 to 48 hours of salt fog before red rust (base metal corrosion) appears.

- Nickel: can survive 96+ hours depending on thickness.

- Silver: performs well but is evaluated differently due to tarnishing versus corrosion.

We encourage our clients to review our testing reports. Transparency in testing builds trust in the longevity of the component.

Conclusion: Ensuring Longevity in Power Distribution

The selection of a plating option for Busbar Copper is a decision that dictates the maintenance cycle, safety, and efficiency of your electrical infrastructure. Whether you choose the cost-efficiency of tin, the high-performance conductivity of silver, or the rugged durability of nickel, the application method matters as much as the material itself.

At JUMAI TECH, we are not just a machine shop; we are partners in your engineering success. From the initial design of Precision Stamping Dies to the final surface finishing of complex busbars and Deep-Drawn Components, we ensure that every micron of plating adds value and reliability to your product.

Do not let corrosion be the weak link in your power chain. If you are developing a new power distribution unit, an EV battery pack, or a custom industrial control system, contact our engineering team today. Let us help you select the precise substrate and plating combination that meets your technical requirements and budget.

Visit us at www.deepdrawtech.com to request a quote or consult with our experts regarding your custom Busbar Copper needs.