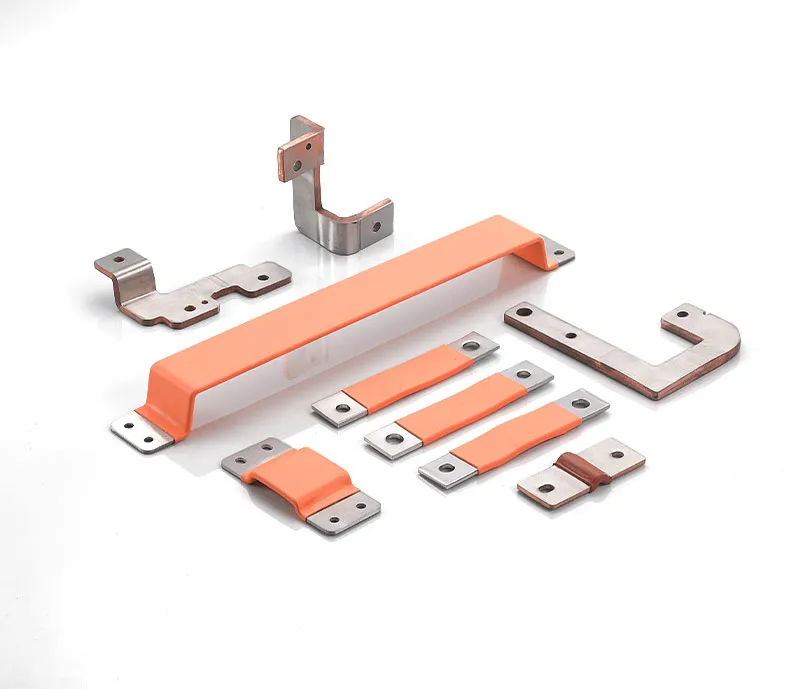

In the rapidly evolving landscape of power distribution, the integrity of your electrical infrastructure is only as strong as its core conductive components. Whether powering next-generation electric vehicles (EVs), massive hyperscale data centers, or renewable energy grids, the humble busbar serves as the critical artery of energy flow. At JUMAI TECH, we have spent years mastering the art of Precision Copper Busbars, Deep-Drawn Components, and Precision Stamping Dies. We understand that sourcing busbar copper is not merely about purchasing metal; it is about securing reliability, efficiency, and compliance with a complex web of international standards.

For engineers and procurement officers navigating the global market, understanding the rigorous standards and testing protocols associated with busbar copper is non-negotiable. A slight deviation in material purity, a failure in coating thickness, or a misunderstanding of thermal expansion rates can lead to catastrophic system failures. This comprehensive guide delves deep into the metallurgy, the regulatory environment (IEC, UL, ASTM, ISO), and the rigorous testing methodologies that ensure your copper components meet the demands of modern engineering.

Table of Contents

The Metallurgy of Excellence: Defining High-Quality Busbar Copper

To understand standards, one must first understand the material itself. Busbar copper is not a generic commodity. In the world of high-performance electrical engineering, the specific grade of copper used dictates the efficiency and longevity of the entire system.

Electrolytic Tough Pitch (ETP) vs. Oxygen-Free Copper

The most commonly utilized grade in standard power distribution is C11000, also known as Electrolytic Tough Pitch (ETP) copper. This material is renowned for its excellent electrical conductivity, typically rated at 100% or 101% IACS (International Annealed Copper Standard). For the majority of general stamping and busbar applications at JUMAI TECH, C11000 provides the perfect balance between cost-effectiveness and high performance. It contains a minute amount of oxygen (0.02% to 0.04%), which actually improves conductivity by scavenging impurities that would otherwise hamper electron flow.

However, for applications requiring extensive deep drawing or brazing in hydrogen-rich atmospheres, C10100 or C10200 (Oxygen-Free Electronic/Copper) becomes essential. Standard ETP copper can suffer from “hydrogen embrittlement” when heated in reducing atmospheres, leading to internal cracking. High-end precision applications, particularly in vacuum electronics or extreme deep-drawn components where material ductility is paramount, demand the superior purity of Oxygen-Free grades.

The Role of Conductivity and IACS Ratings

The gold standard for measuring the capability of busbar copper is the International Annealed Copper Standard (IACS). Established in 1913, 100% IACS represents a conductivity of 58 MS/m (megasiemens per meter). Modern metallurgical processes often allow high-purity copper busbars to exceed this, reaching 101% or even 102% IACS.

At JUMAI TECH, every batch of raw material is scrutinized against these conductivity benchmarks. If a supplier provides copper that tests at 98% IACS when the specification demands 101%, the resulting resistive heating ($I^2R$ losses) in a high-amperage switchgear cabinet could exceed thermal limits, violating safety standards.

| Copper Grade (UNS) | Common Name | Min. Conductivity (IACS) | Oxygen Content | Typical Application |

| C10100 | Oxygen-Free Electronic (OFE) | 101% | < 0.0005% | Vacuum electronics, Cryogenics |

| C10200 | Oxygen-Free (OF) | 100-101% | < 0.0010% | Deep-drawn parts, Brazed assemblies |

| C11000 | Electrolytic Tough Pitch (ETP) | 100-101% | 0.02-0.04% | General switchgear, Control panels |

| C12200 | Phosphorized (DHP) | 85% | 0.015-0.040% | Tubing, Heat exchangers (Lower conductivity) |

Navigating the Global Standards Maze

When JUMAI TECH exports precision stamped dies or copper busbars to clients in Germany, the USA, or Japan, we are not just shipping metal; we are shipping compliance. Global markets rely on distinct standards bodies to ensure safety and interchangeability.

North American Standards: ASTM and UL

In the United States and Canada, the governing body for material properties is predominantly ASTM International. ASTM B187 is the definitive specification for Copper, Bus Bar, Rod, and Shapes. It outlines the requirements for tensile strength, Rockwell hardness, and electrical resistivity.

However, the application of the busbar falls under Underwriters Laboratories (UL). UL 67 (Panelboards) and UL 857 (Busways) are the critical safety standards. These standards do not just test the copper; they test the assembly. They dictate rigorous short-circuit withstand tests and temperature rise limits. For instance, a connection point on a busbar copper assembly usually cannot exceed a 30°C rise over ambient temperature for standard terminations, ensuring the insulation does not degrade.

For more on ASTM specifications, you can reference the ASTM International Official Website.

European and International Standards: IEC and EN

Across the Atlantic, the International Electrotechnical Commission (IEC) sets the tone. IEC 61439 is the bible for low-voltage switchgear and control gear assemblies. Unlike older standards that allowed for “Type Tested Assemblies” (TTA), IEC 61439 focuses on design verification.

This standard places a massive emphasis on thermal management. It requires that busbar copper systems be verified to handle the heat generated during full-load operations. It also dictates “Creepage” and “Clearance” distances—the physical spacing required between copper bars to prevent electrical arcing. Furthermore, EN 13601 is the specific European material standard for copper rod and bar for electrical purposes, closely mirroring ASTM B187 but with metric dimensional tolerances.

Chinese Standards: GB/T

For the domestic market in China, which serves as a massive hub for global manufacturing, the GB/T 5585.1 standard governs copper and copper alloy busbars for electrical purposes. While largely harmonized with IEC standards, nuanced differences in chemical composition allowances and mechanical hardness classifications exist. JUMAI TECH’s facility is equipped to cross-reference these standards, ensuring a product designed for a GB framework can be adapted to meet DIN or ANSI requirements.

Critical Testing Methodologies for Busbar Copper

Validation is the backbone of quality assurance. At JUMAI TECH, simply trusting the mill certificate is insufficient. We employ a rigorous battery of tests to ensure every piece of busbar copper meets the strict requirements of our global clientele.

Electrical Conductivity and Resistivity Testing

The primary test for any busbar is its ability to carry current. We utilize Eddy Current Conductivity Meters for non-destructive testing. This method induces a current into the copper and measures the impedance, providing an instant readout in % IACS.

For more precise laboratory analysis, a Kelvin Bridge (4-wire measurement) is used. By separating the current-carrying wires from the voltage-sensing wires, we eliminate the resistance of the test leads themselves, measuring the pure resistance of the busbar copper. This is critical for calculating the exact voltage drop across a custom-designed busbar network.

Mechanical Properties: Tensile and Hardness Testing

While copper is conductive, it is also a structural element. In the event of a short circuit, huge electromagnetic forces try to rip the busbars apart. The copper must possess sufficient tensile strength to resist these dynamic stresses.

We adhere to ASTM E8 methodology for tensile testing. A sample is stretched until failure to determine its Yield Strength and Ultimate Tensile Strength. Additionally, hardness testing (Vickers or Rockwell) is vital, particularly for parts that will undergo deep drawing or precision stamping. Copper that is too hard (“Full Hard”) may crack during bending, while copper that is too soft (“Dead Soft”) may deform under the torque of bolted connections.

Coating Thickness and Adhesion

Raw busbar copper oxidizes over time, creating a resistive film. To prevent this, most global applications require tin, silver, or nickel plating.

- Tin Plating: Common for general industrial use. We test per ASTM B545, verifying thickness (usually 3 to 10 microns) to ensure corrosion resistance.

- Silver Plating: Essential for high-frequency or high-temperature applications. Tested per ASTM B700.

Testing involves X-ray Fluorescence (XRF) to measure coating thickness down to the micro-inch without damaging the part. Adhesion is often tested via a “Bend Test,” where the busbar is bent 180 degrees; if the plating peels or flakes, the part is rejected.

Thermal Performance and Ampacity Verification

One of the most complex aspects of designing with busbar copper is determining “Ampacity”—the maximum current a conductor can carry before its temperature exceeds safe limits. This is not a fixed number; it depends on the copper’s cross-sectional area, the ambient temperature, and airflow.

The Temperature Rise Test

According to IEC 61439, the temperature rise of the busbar surface must not damage adjacent materials. JUMAI TECH utilizes thermal modeling software alongside physical testing to verify these limits. A common rule of thumb is a design density of 2A/mm² for copper, but this is an oversimplification.

In our testing, we pass a calibrated high current through the busbar assembly and monitor the temperature using thermocouples until thermal equilibrium is reached. If a busbar designed for 1000A reaches 120°C (when the limit is 105°C), the design must be altered—either by increasing the busbar copper cross-section or changing the configuration to improve radiative cooling.

Skin Effect in AC Applications

For Alternating Current (AC) applications, specifically at higher frequencies, the current tends to flow on the outer surface of the conductor—a phenomenon known as the “Skin Effect.” This reduces the effective cross-sectional area of the busbar copper.

In these scenarios, a thick solid bar is inefficient. JUMAI TECH advises clients on using laminated busbars or hollow tubes to maximize surface area relative to volume. Testing for AC resistance involves using LCR meters at specific frequencies to validate that the impedance remains within calculated tolerances.

Deep-Drawn Components: The Intersection of Ductility and Strength

Beyond standard flat bars, JUMAI TECH specializes in Deep-Drawn Components. This process involves pulling a flat copper blank into a die to create 3D shapes, such as battery caps or capacitor housings.

The Importance of Grain Size

For deep drawing, the microstructure of the busbar copper is critical. If the grain size is too large, the surface of the drawn part will exhibit a rough, “orange peel” texture, which is unacceptable for precision electronic contacts. If the grain size is too small, the metal may lack the ductility to stretch without tearing.

We adhere to ASTM E112 for determining average grain size. Our deep-drawn copper components are rigorously inspected for wall thickness uniformity. Unlike simple bending, deep drawing thins the material. We use ultrasonic thickness gauges to ensure that the thinnest point of the drawn component still meets the electrical and structural requirements of the design.

Precision Stamping Dies: Ensuring Repeatability

The quality of a copper busbar is determined by the quality of the tool that cuts it. JUMAI TECH designs and manufactures in-house Precision Stamping Dies.

Die Materials and Maintenance

Cutting copper can be deceptively difficult. Copper is “gummy”; it tends to stick to the punch and die, leading to burrs. A burr on a busbar copper edge acts as a concentration point for electrical field stress (Corona discharge) in high-voltage applications, potentially leading to arcing.

Our dies are manufactured from high-grade tool steels (like D2 or carbide) and coated with TiN (Titanium Nitride) to reduce friction. We implement a strict maintenance schedule based on “hit counts.” After a specific number of strokes, dies are sharpened. We inspect the cut edges of our busbars using optical comparators to ensure burr height does not exceed global standards (typically < 0.05mm for high-precision electronics).

Surface Treatment and Environmental Protection

Copper is reactive. In humid or corrosive environments (like offshore wind farms or chemical plants), bare copper will degrade.

Salt Spray Testing

To validate our surface treatments, we utilize Salt Spray (Fog) Testing per ASTM B117. Plated busbar copper samples are placed in a controlled chamber and exposed to a saline mist for periods ranging from 24 to 500 hours. This accelerates the corrosion process. A pass requires no red rust (base metal corrosion) and limited white rust (plating corrosion) after the specified duration.

Whisker Mitigation

For tin-plated busbars, a phenomenon known as “Tin Whiskers”—microscopic conductive filaments that grow from the surface—can cause short circuits. This is a massive concern in the aerospace and data center sectors. JUMAI TECH employs specific plating baths and reflow processes to mitigate whisker growth, adhering to JEDEC standards (JESD201) to ensure long-term reliability.

Strategic Sourcing and Supply Chain Traceability

In the global market, traceability is as important as the product itself. When a client receives a shipment of busbar copper components from JUMAI TECH, they receive full documentation.

Material Test Reports (MTRs)

Every batch is accompanied by an MTR from the raw material mill. This document lists the specific Heat Number (for tracking), the chemical composition (proving it is C11000 or C10100), and the mechanical properties. We archive these records, ensuring that if a defect is discovered five years down the line, we can trace it back to the specific mining lot.

Conflict Minerals Compliance

Global manufacturers are increasingly scrutinized regarding the ethical sourcing of materials. We ensure our supply chain is free from “Conflict Minerals” (Tin, Tantalum, Tungsten, Gold) sourced from conflict zones, adhering to the Dodd-Frank Act guidelines and the RMI (Responsible Minerals Initiative) standards.

JUMAI TECH: Your Partner in Precision and Compliance

The landscape of busbar copper standards is vast and unforgiving. From the atomic structure of the metal to the microscopic thickness of the plating, every detail matters. At JUMAI TECH (www.deepdrawtech.com), we do not simply follow these standards; we integrate them into our DNA.

Our integrated approach—combining raw material analysis, precision stamping die fabrication, deep drawing expertise, and comprehensive lab testing—makes us more than a vendor. We are a technical partner capable of navigating the complexities of IEC, UL, and ASTM requirements on your behalf.

Whether you are designing the battery pack for an autonomous vehicle or the switchgear for a nuclear power plant, the quality of your connection determines the safety of your system. Choose JUMAI TECH for precision, reliability, and global compliance. Contact our engineering team today to discuss how we can tailor our busbar copper solutions to meet your specific testing and standard requirements.