In the rapidly evolving landscape of power distribution and electronic engineering, the debate between using a flexible copper busbar versus a traditional solid copper bar is more than just a matter of preference—it is a critical decision that impacts thermal efficiency, installation speed, and long-term system reliability. As the Editor-in-Chief at JUMAI TECH (www.deepdrawtech.com), and having spent years on the factory floor overseeing the production of precision copper busbars, deep-drawn components, and precision stamping dies, I have witnessed firsthand the shift in the industry. We have moved from the era of massive, static switchgear to compact, high-vibration environments like electric vehicles (EVs) and renewable energy inverters, where the rules of connectivity have changed.

While solid copper bars have been the backbone of electrical infrastructure for over a century, offering rigidity and straightforward conductivity, they face significant limitations in modern applications where space is at a premium and thermal expansion is a constant threat. This article will serve as a definitive guide, comparing these two technologies deeply, backed by data, physics, and the practical manufacturing expertise we apply every day at JUMAI TECH. Whether you are designing a battery management system (BMS) or a massive industrial control panel, understanding the nuances of the flexible copper busbar is essential for optimizing your power architecture.

Table of Contents

The Anatomy of Power: Defining the Contenders

Before we dive into the comparative analysis, it is crucial to understand exactly what differentiates these two components at a structural and metallurgical level. The choice of material form factor dictates the electrical performance and mechanical resilience of your entire assembly.

The Traditional Solid Copper Bar

The solid copper busbar is typically machined from Electrolytic Tough Pitch (ETP) copper or Oxygen-Free (OF) copper. It is a rigid, monolithic conductor. In our workshop at JUMAI TECH, we often produce these using precision stamping dies to create specific shapes, holes, and bends. They are excellent for stationary applications where the distance between connection points is fixed and guaranteed not to change. However, their rigidity is their Achilles’ heel; they transmit vibration directly to the terminals (like IGBTs or capacitors), potentially causing micro-fractures in solder joints over time.

The Evolution of the Flexible Copper Busbar

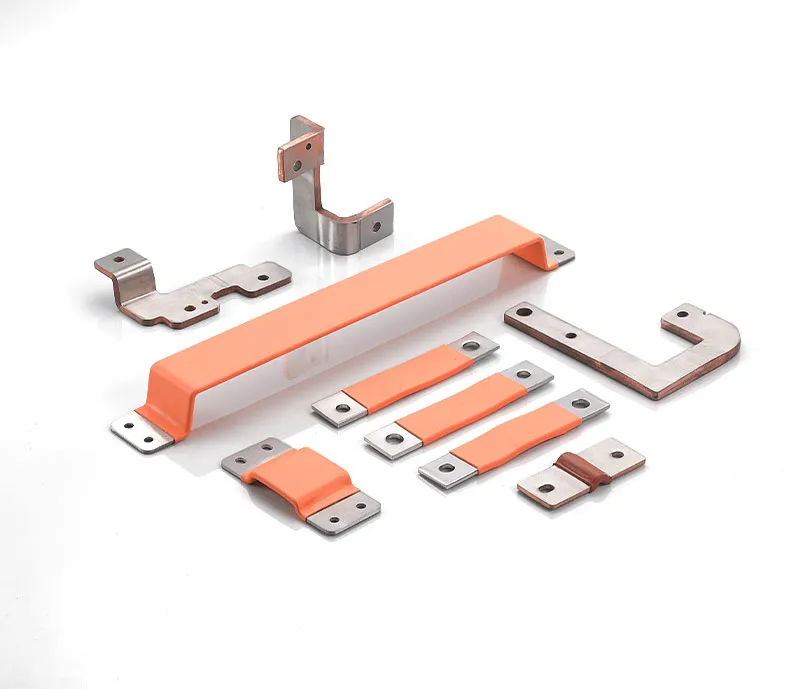

A flexible copper busbar is an engineered solution designed to decouple mechanical stress from electrical conduction. There are generally two main types we encounter in high-end manufacturing:

- Laminated Flexible Busbars: These consist of multiple stacked layers of thin electrolytic copper strips (foils), protected by an insulation layer (often PVC or silicone). They can slide against each other, allowing the bar to bend and twist.

- Braided Copper Shunts: These are made of woven copper wires, offering multi-directional flexibility, often used for grounding or extreme vibration environments.

The magic of the flexible variant lies in its ability to carry high currents while acting as a mechanical shock absorber. This duality is why they are becoming the standard in sectors ranging from telecommunications to automotive manufacturing.

Electrical Performance: Ampacity and Skin Effect

When engineers select a conductor, the first question is usually, “How much current can it handle?” However, the answer is rarely simple. Current carrying capacity (ampacity) is heavily influenced by surface area, frequency, and thermal dissipation.

Addressing the Skin Effect in High-Frequency Applications

In DC applications, current flows uniformly through the cross-section of the conductor. However, in AC applications—particularly in high-frequency power electronics like solar inverters or variable frequency drives (VFDs)—we encounter the “Skin Effect.” This phenomenon causes the current to crowd toward the surface of the conductor, leaving the center largely unutilized.

A solid bar has a relatively low surface-area-to-volume ratio. As frequency increases, its effective resistance rises, leading to heat generation. In contrast, a flexible copper busbar, particularly the laminated variety, is composed of many thin layers. This specific geometry significantly increases the surface area available for current flow.

Technical Note: According to data referenced by theInstitute of Electrical and Electronics Engineers (IEEE), laminated conductors can reduce AC resistance by up to 20% compared to solid bars of the same cross-section at frequencies above 1 kHz.

Thermal Dissipation and Ampacity Ratings

Heat is the enemy of electronic components. Flexible busbars often have a higher ampacity rating than solid bars of the equivalent cross-sectional area. Why? Because the laminated structure, even when insulated, allows for slightly better thermal radiation due to the increased surface area of the individual foils before they are bonded at the terminals.

At JUMAI TECH, when we design custom solutions, we calculate the temperature rise ($\Delta T$). A flexible busbar typically runs cooler because it can be routed away from hot spots more easily than a rigid bar. Below is a comparative look at ampacity based on a $35^\circ C$ temperature rise:

| Conductor Type | Cross Section (mm2) | Dimensions (mm) | Approx. Ampacity at ΔT=35∘C (A) | Notes |

| Solid Copper Bar | 200 | 40 x 5 | 600 | Limited by surface area cooling. |

| Flexible Copper Busbar | 200 | 20 x 1 x 10 layers | 670 | Higher surface area improves cooling. |

| Round Copper Cable | 200 | ~18mm Diameter | 520 | Worst air cooling due to bundle density. |

Data approximates standard industrial conditions. Specific results depend on insulation type and ambient airflow.

Mechanical Reliability: Vibration and Thermal Expansion

The primary driver for the adoption of the flexible copper busbar is not just electrical efficiency; it is mechanical survival. In modern power electronics, components expand, contract, and vibrate.

The Coefficient of Thermal Expansion (CTE) Challenge

All materials expand when heated. Copper has a thermal expansion coefficient of approximately $16.5 \times 10^{-6} / K$. In a large power distribution unit, if a solid copper bar connects two rigid terminals, the expansion caused by electrical heating creates immense lateral force on those terminals.

Imagine a solid bar connecting two ceramic capacitors. As the bar heats up, it pushes outward. Since the bar is rigid, that force has nowhere to go but into the delicate ceramic terminals, leading to cracking and catastrophic failure. A flexible copper busbar absorbs this expansion within its own structure. The layers bow or flex slightly, exerting virtually zero stress on the connected components. This “stress relief” capability is vital for the longevity of the equipment.

Vibration Damping in Automotive and Industrial Settings

In the electric vehicle sector, vibration is constant. A rigid connection acts as a lever arm; if one end vibrates, the stress is magnified at the connection point. We have seen solid bars shear off bolts due to metal fatigue under high-frequency vibration.

Flexible busbars act as dampers. Their layered or braided construction dissipates mechanical energy through internal friction between the layers. For our clients manufacturing heavy machinery or EV battery packs, we almost exclusively recommend flexible solutions for inter-module connections to ensure the vehicle passes rigorous road vibration tests.

Space Efficiency and Design Freedom

As a manufacturer of Precision Stamping Dies and Deep-Drawn Components, I understand that space is money. Enclosures are getting smaller, and packing more power into less volume is the industry mandate.

The Bending Radius Advantage

Solid copper bars require specialized bending tools. When you bend a solid bar, you must account for the minimum bend radius (usually $1x$ to $2x$ the thickness) to avoid cracking the outer edge or wrinkling the inner edge. Furthermore, once bent, a solid bar cannot be adjusted. If the design tolerances are off by 2mm, the part is scrap.

A flexible copper busbar offers unparalleled agility.

- Tight Turns: They can be folded over on themselves to make 180-degree turns in extremely tight spaces.

- Twisting: Laminated bars can be twisted 90 degrees to change orientation from horizontal to vertical planes, something impossible with a solid flat bar without complex machining.

- Routing: They can snake around obstacles, structural pillars, or other components, much like a cable, but with the power density of a bar.

Reducing Enclosure Size

Because flexible bars can be bent sharply and do not require large radii, engineers can reduce the air gap between components. This allows for smaller overall cabinet dimensions. In data center applications, where floor space costs thousands of dollars per square foot, the ability to shrink a Power Distribution Unit (PDU) by 15% using flexible busbars is a massive value proposition.

Manufacturing and Customization at JUMAI TECH

At JUMAI TECH, we specialize in the transition from raw material to finished component. Understanding how these bars are made helps in selecting the right one.

Diffusion Bonding vs. Press Welding

For high-quality flexible busbars, the connection areas (the ends) must be solid to allow for drilling and bolting. We utilize two primary technologies:

- Press Welding / Fusion Welding: The layers are fused together using heat and pressure. This is standard for many industrial applications.

- Molecular Diffusion Bonding: This is a superior process where the copper layers are compressed under high heat in a vacuum or inert atmosphere until the atoms migrate across the boundary. The result is a monolithic block of copper at the ends with no filler metal or solder. This ensures the lowest possible contact resistance.

Insulation Technology

The insulation on a flexible copper busbar is not just plastic tape. It is usually an extruded high-grade PVC, TPE, or silicone sleeve that is applied before the ends are stamped.

- Dielectric Strength: Our standard insulation is rated for 1000V AC / 1500V DC.

- Flame Retardancy: We adhere to UL 94 V-0 standards, ensuring the material self-extinguishes in case of fire.

Comparing this to solid bars: insulating a solid bar usually requires post-production powder coating or heat-shrink tubing, which adds an extra step and cost to the manufacturing process.

Cost Analysis: Initial Price vs. Total Cost of Ownership (TCO)

Procurement managers often look at the line-item cost and see that a flexible copper busbar is more expensive per meter than a standard solid copper bar. This is true; the manufacturing process is more complex. However, smart engineering looks at the Total Cost of Ownership.

Installation Time Savings

Installing solid bars is labor-intensive. It often requires:

- Precise alignment of cabinets.

- Shimming to fill gaps if tolerances are not perfect.

- Torquing bolts, then re-torquing after a settling period.

Flexible bars effectively eliminate alignment issues. Because they have “play,” an installer can easily connect two terminals that are slightly misaligned (e.g., by 5mm) without forcing the connection. This can reduce assembly time by up to 40%. When you factor in labor rates in Europe or North America, the flexible bar becomes the cheaper option.

Inventory and Modularity

With solid bars, every unique connection requires a unique part number and a specific die or bending program. With flexible bars, a standard length can often serve multiple locations because the installer can adjust the bend geometry on the fly. This reduces SKU count and simplifies inventory management for our clients.

Application Scenarios: Where Flexible Wins

While solid bars still hold their ground in long, straight power runs (like busway systems in ceilings), flexible bars dominate in specific high-tech sectors.

1. Electric Vehicle (EV) Battery Packs

Inside a battery pack, hundreds of cells must be connected. The pack swells during charging and discharging. Using rigid bars would stress the battery terminals, risking fires. Flexible busbars accommodate this “breathing” of the battery pack. Furthermore, in the event of a crash, flexible bars can deform without snapping, maintaining circuit integrity for safety systems.

2. Renewable Energy Inverters

Solar inverters convert DC to AC, switching at high frequencies. As mentioned earlier, the skin effect makes laminated flexible bars electrically superior here. Additionally, inverters generate significant heat and vibration from cooling fans. The damping properties of flexible copper are essential for the longevity of the IGBT modules used in these devices. More information on renewable energy standards can be found through the International Electrotechnical Commission (IEC).

3. Switchgear and Panel Boards

In retrofitting old switchgear, dimensions rarely match perfectly. Flexible busbars act as the universal adapter, allowing new, modern breakers to be fitted into old chassis without expensive custom copper work.

Quality Standards and Future Trends

At JUMAI TECH, we strictly adhere to international standards to ensure our flexible copper busbar products meet global requirements.

- UL 758: Standard for Appliance Wiring Material.

- ISO 9001 & IATF 16949: Essential for automotive quality management.

The Future is Hybrid

The future of power electronics isn’t purely flexible or purely solid. It is hybrid. We are seeing designs that utilize solid Deep-Drawn Components for the main structural power backbone, utilizing our precision stamping dies, coupled with short flexible jumpers for the final connection to sensitive electronics. This hybrid approach optimizes cost (using solid copper where flexibility isn’t needed) and performance (using flexible copper where vibration or thermal expansion is an issue).

Conclusion: Making the Right Connection

The transition from solid to flexible conductors represents a maturation in power engineering. While the solid bar remains a cost-effective workhorse for static infrastructure, the flexible copper busbar is the sophisticated solution for dynamic, high-density, and high-performance applications. It solves thermal expansion headaches, mitigates vibration risks, combats the skin effect, and drastically reduces installation time.

At JUMAI TECH (www.deepdrawtech.com), we leverage our deep expertise in Precision Copper Busbars and Stamping Dies to deliver solutions that fit your exact needs. Whether you need the brute strength of a solid bar or the agile performance of a flexible laminated shunt, our engineering team is ready to assist. We don’t just supply parts; we supply the connectivity that powers the future.

If you are designing the next generation of power electronics, consider the “flex” advantage. It might just be the most rigid decision you make for your system’s reliability.