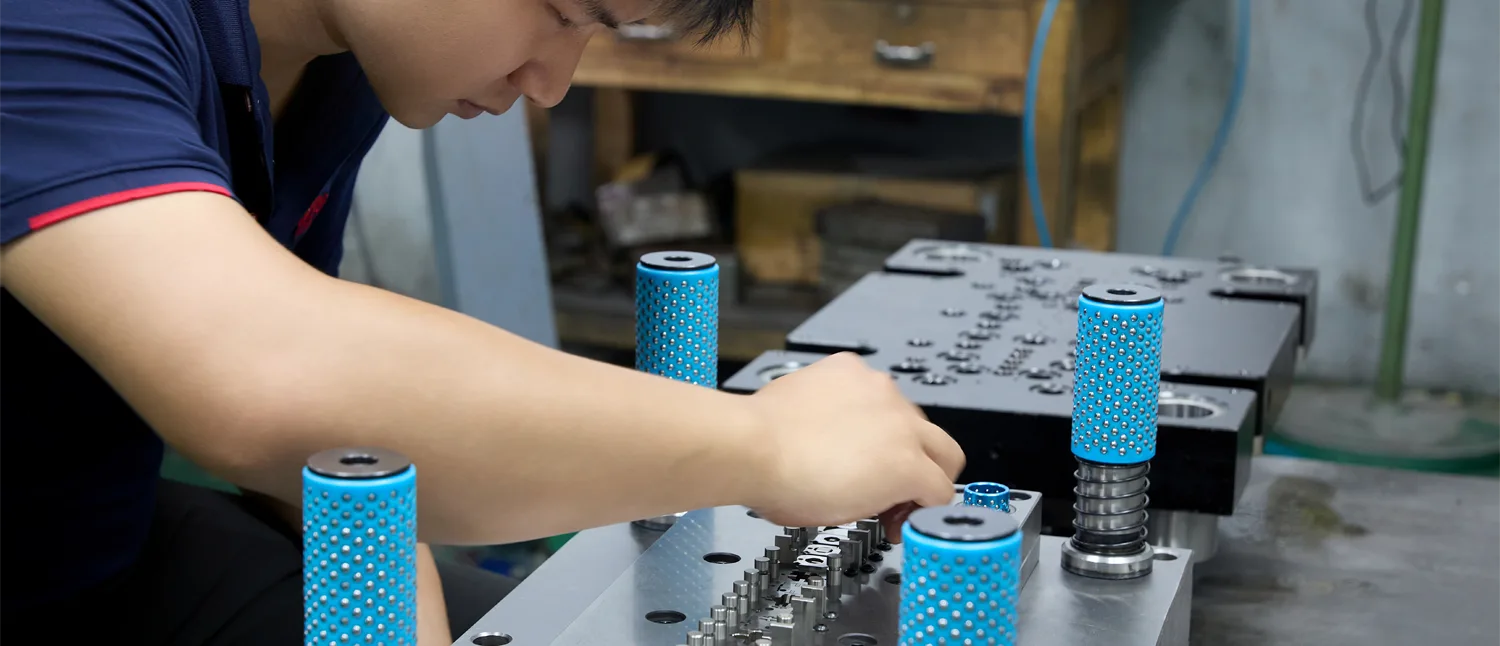

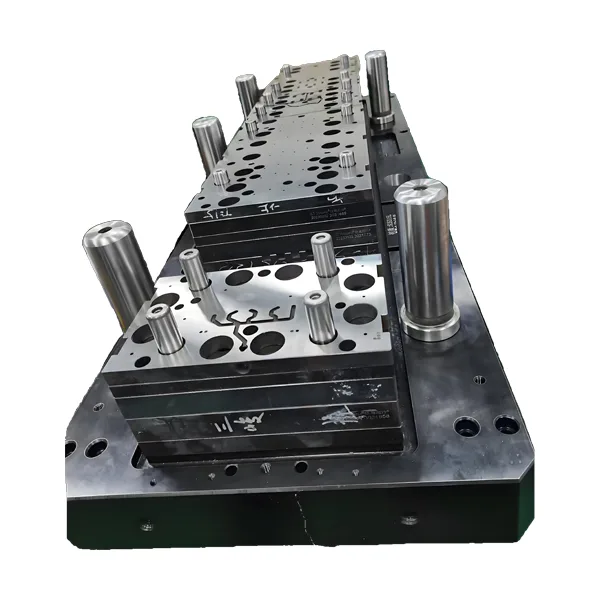

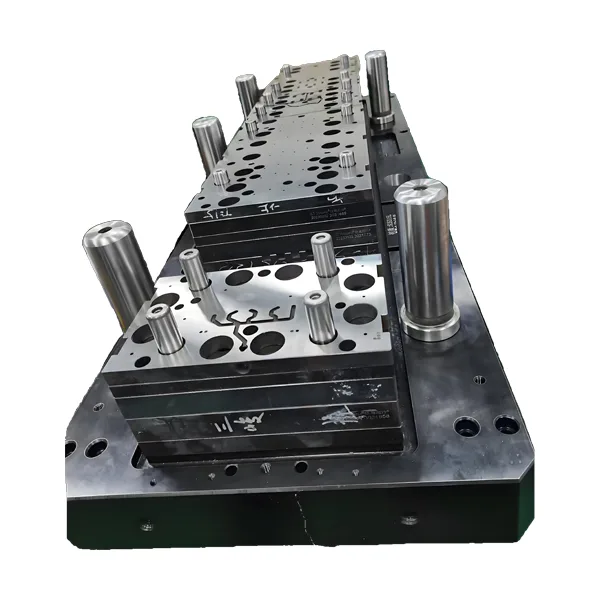

In the high-stakes world of modern manufacturing, the longevity and precision of your tooling are not just metrics—they are the definition of your profitability. As professionals who have spent decades on the shop floor at JUMAI TECH, specializing in Precision Copper Busbars, Deep-Drawn Components, and Precision Stamping Dies, we understand that a stamping die is more than a block of steel. It is a dynamic system that breathes, flexes, and, most critically, heats up.

The number one enemy of a high-performance stamping die is uncontrolled thermal energy. When a die strikes metal thousands of times per hour, the friction and deformation energy generated are immense. Without a scientifically engineered approach to cooling and lubrication, you face premature tool wear, galling, and dimensional instability. This guide explores the advanced engineering behind optimizing cooling and lubrication paths, ensuring your stamping operations run faster, longer, and with higher precision.

Table of Contents

The Thermodynamics of the Stamping Process

To optimize a system, one must first understand the forces at play. In high-speed stamping, particularly with hard materials used in deep-drawn components, up to 90% of the deformation work is converted into heat. This heat does not dissipate instantly; it accumulates in the punch and the die matrix.

Understanding Thermal Saturation

When a stamping die operates continuously, it eventually reaches a state of thermal saturation. If the heat input exceeds the heat removal capacity, the tool steel begins to expand. Even a microscopic expansion in a precision die—where clearances are measured in microns—can lead to catastrophic seizing or “galling.”

According to research by the Society of Manufacturing Engineers (SME), thermal fatigue is a leading cause of die failure in high-volume production. The heat alters the material properties of the die, softening the hardened surfaces and making them susceptible to abrasive wear. Therefore, the goal of cooling optimization is not just to “cool” the tool, but to maintain a consistent thermal equilibrium, ensuring the gap between the punch and die remains constant throughout the production run.

The Role of Friction in Heat Generation

Friction occurs at three distinct interfaces:

- Tool-Workpiece Interface: Where the punch contacts the sheet metal.

- Internal Deformation: The shearing of the metal’s grain structure.

- Tool-Guide Interface: The friction between the stripper plate, guide posts, and the punch.

Effective lubrication is the primary defense against this frictional heat. However, lubrication alone is rarely enough for deep-drawn parts or high-speed progressive dies; it must be paired with an active heat extraction system (cooling channels).

Engineering Advanced Cooling Channels

Gone are the days when drilling a few straight water lines through a die block was considered sufficient. At JUMAI TECH, we utilize computational fluid dynamics (CFD) to design cooling paths that conform to the geometry of the tool.

From Straight Lines to Conformal Cooling

Traditional cooling involves drilling straight intersecting holes. While cost-effective, this method often leaves “hot spots” in complex areas of the stamping die, such as the tip of a deep-draw punch. This uneven cooling causes thermal stress, leading to premature cracking.

Conformal Cooling, a technology often associated with injection molding but increasingly vital in stamping, utilizes 3D printing (Direct Metal Laser Sintering – DMLS) to create cooling channels that follow the contour of the die surface. This ensures that the cooling medium is always at an optimal distance from the heat source, providing uniform heat extraction.

Note: A study published in the International Journal of Advanced Manufacturing Technology indicates that conformal cooling channels can reduce the temperature difference across the die surface by up to 40%, significantly extending tool life.

Turbulent Flow vs. Laminar Flow

The efficiency of a cooling path relies heavily on the flow dynamics of the coolant. Laminar flow (smooth, layered flow) is inefficient for heat transfer because the fluid layers insulate the center of the stream from the channel walls. We aim for turbulent flow, where the fluid mixes chaotically, maximizing contact with the channel walls and enhancing heat absorption.

We calculate the Reynolds Number (Re) to ensure turbulence:

Where:

- ρ is the fluid density

- v is the velocity

- DH is the hydraulic diameter

- μ is the dynamic viscosity

Generally, a Reynolds number above 4000 is required to achieve turbulent flow in cooling channels. This is why pump pressure and channel diameter must be carefully calculated during the stamping die design phase.

Lubrication Path Strategies for High-Speed Stamping

Lubrication is the lifeblood of the stamping process. It serves two purposes: reducing the coefficient of friction and flushing away debris (fines) that could score the part.

Micro-Lubrication and Precision Application

Flooding the die with oil is messy, expensive, and environmentally unfriendly. The industry trend, which JUMAI TECH fully supports, is toward Minimum Quantity Lubrication (MQL). This involves delivering precise micro-droplets of lubricant exactly where they are needed, often through internal channels within the stamping die itself.

By integrating lubrication paths directly into the stripper plates or punches, we can deliver oil to the cutting edge before contact is made. This “through-the-tool” lubrication ensures that the critical zone is protected even during the first millisecond of impact.

Choosing the Right Lubricant Viscosity

The choice of lubricant is dictated by the severity of the operation.

- Light Stamping: Low viscosity, evaporative oils are used. They provide boundary lubrication and leave little residue.

- Deep Drawing: High viscosity oils with Extreme Pressure (EP) additives (like sulfur or chlorine) are required. These additives react with the metal surface under high heat to form a protective chemical layer.

Comparative Data: Lubrication Methods

The following table illustrates the efficiency differences between standard flood cooling and optimized internal path lubrication.

| Feature | Flood Lubrication | Internal Path MQL (Optimized) |

| Lubricant Consumption | High (Wasteful) | Low (Precision Dosing) |

| Heat Removal | Moderate | High (Targeted) |

| Tool Life Extension | Baseline | +25% to 40% |

| Part Cleanliness | Poor (Requires Washing) | Excellent (Near Dry) |

| Environment Impact | High | Low |

Material Selection for Thermal Management

The material of the stamping die itself plays a crucial role in cooling. Not all tool steels conduct heat equally. When designing dies for Precision Copper Busbars, which are highly conductive themselves, the thermal balance is different compared to stamping stainless steel.

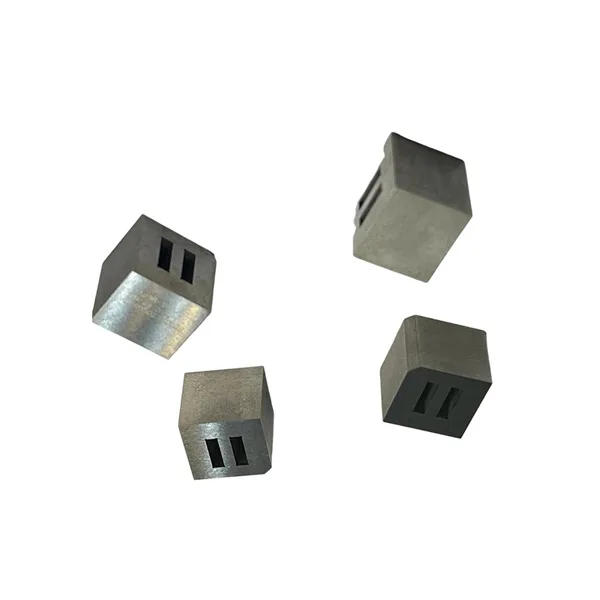

High Thermal Conductivity Tool Steels

Standard D2 tool steel provides excellent wear resistance but has relatively poor thermal conductivity. For applications prone to overheating, we often recommend specialized powder metallurgy (PM) steels or copper-alloy based die inserts (like Ampco bronze) for specific forming sections.

Ampco Bronze inserts have a thermal conductivity 5 to 10 times higher than tool steel. By placing these inserts in high-heat zones and backing them with water cooling channels, we can extract heat at a rate that standard steel simply cannot match. This prevents the “work hardening” of the stamped part that occurs when the tool gets too hot.

Surface Coatings and Heat Resistance

Coatings like TiCN (Titanium Carbonitride) or AlCrN (Aluminum Chromium Nitride) are essential. They provide a hard, slick barrier that reduces friction (and thus heat generation) in the first place.

- TiCN: Excellent for general purpose, providing a low coefficient of friction.

- AlCrN: Superior thermal stability, capable of withstanding temperatures up to 1100°C without breaking down.

According to Oerlikon Balzers, applying the correct PVD coating can reduce the coefficient of friction from 0.8 (steel on steel) to less than 0.2, drastically lowering the heat load on the cooling system.

The Impact of Surface Finish on Lubrication Retention

An often-overlooked aspect of lubrication path optimization is the surface finish of the stamping die. A mirror-polished surface is not always the best for lubrication.

The Significance of Micro-Pockets

While the forming surfaces should be smooth to prevent marking the part, the guiding surfaces benefit from specific texturing. Micro-pockets or laser-textured surfaces can act as reservoirs for lubricant. When pressure is applied, these pockets release oil into the interface, maintaining a hydrodynamic film even under heavy loads.

At JUMAI TECH, we utilize advanced EDM (Electrical Discharge Machining) techniques to leave controlled surface topography in non-critical areas of the die to enhance oil retention. This prevents “dry start” conditions where the lubricant creates a vacuum seal and fails to flow into the gap.

Avoiding the “Wiper Effect”

If the clearance between the punch and stripper is too tight and the surface is too smooth, the stripper can act like a wiper blade, removing all oil from the punch before it enters the metal. Designing the lubrication path involves creating “reliefs” or slight undercuts in the guide bushings to ensure a film of oil remains attached to the punch during the working stroke.

Integration with Smart Manufacturing (Industry 4.0)

The future of stamping die maintenance is predictive, not reactive. Modern cooling and lubrication systems are now being integrated with sensors.

Real-Time Monitoring

By embedding thermocouples and flow sensors within the cooling paths, we can monitor the internal temperature of the die in real-time. If a cooling channel becomes clogged with scale or rust, the flow rate drops, and the temperature spikes.

- Flow Sensors: Detect blockages in cooling lines immediately.

- Pressure Sensors: Monitor the lubricant delivery system to ensure pressure is maintained at the nozzle.

This data allows for predictive maintenance. Instead of waiting for a part to be rejected due to thermal distortion, the machine controller can alert the operator that “Cooling Zone 3” is underperforming. This level of control is standard for the high-end tooling solutions we provide for our global clients.

Maintenance of Cooling and Lubrication Systems

Even the best-designed system will fail without proper maintenance. Over time, water channels build up scale (calcium deposits) and lubrication lines can get clogged with sludge or bacterial growth.

Cleaning Cooling Channels

To maintain the turbulent flow required for heat transfer, channels must be kept smooth and clean.

- Chemical Flushing: Using mild acidic solutions to dissolve scale buildup.

- Mechanical Cleaning: Using flexible brushes for straight drilled lines.

- Filtration: Ensuring the cooling water is filtered to remove particulates that could block conformal cooling passages (which often have smaller diameters).

Managing Lubricant Integrity

Lubricants can degrade over time due to oxidation and bacterial contamination. Regular testing of the lubricant’s viscosity and pH levels is essential. Furthermore, the filters in the MQL system must be changed regularly to prevent nozzle blockage. A blocked lubrication path in a high-speed progressive die can lead to a catastrophic crash in seconds.

Conclusion: The JUMAI TECH Standard

Optimizing the cooling and lubrication paths of a stamping die is a multidisciplinary challenge involving thermodynamics, fluid mechanics, and materials science. It is not an area where corners should be cut. A die that runs cool runs true. It produces parts with tighter tolerances, requires less maintenance, and ultimately yields a lower cost per part.

At JUMAI TECH, we do not just manufacture parts; we engineer the entire ecosystem of production. Whether you need Precision Copper Busbars for electrical applications or complex Deep-Drawn Components for automotive use, our tooling assumes the highest standards of thermal and tribological management.

We invite you to audit your current stamping operations. Are your dies overheating? Are you experiencing inconsistent tool life? It may be time to re-evaluate your cooling and lubrication strategies. Contact our engineering team today, and let us bring our years of specialized experience to your production line.

For more insights into precision manufacturing, visit our technical library at www.deepdrawtech.com.

Glossary of Terms

- Galling: A form of wear caused by adhesion between sliding surfaces, leading to material transfer and surface damage.

- Conformal Cooling: Cooling channels that follow the shape of the part or tool surface to provide uniform cooling.

- MQL (Minimum Quantity Lubrication): A lubrication method that uses a very small amount of fluid, usually sprayed as a mist, to reduce waste and environmental impact.

- Reynolds Number: A dimensionless quantity used to predict fluid flow patterns (laminar vs. turbulent).

- Tribology: The science and engineering of interacting surfaces in relative motion, including the study of friction, lubrication, and wear.