The global transition toward electric mobility is no longer a prediction; it is an accelerating reality. As the automotive industry pivots away from internal combustion engines, the heart of the vehicle has shifted from the engine block to the battery pack. For engineers and designers, the challenge has moved beyond simply storing energy to managing it with supreme efficiency. In this high-stakes environment, the humble interconnect system has emerged as a critical component. Specifically, the rigid busbar has proven itself to be the superior solution for high-voltage and high-current applications within Electric Vehicle (EV) battery packs.

At JUMAI TECH, we have spent years refining the art of custom metal fabrication. From our roots in precision stamping dies to our advanced capabilities in deep-drawn components and precision copper busbars, we understand that the difference between a good EV and a great one often lies in the quality of its electrical architecture. This guide explores why custom rigid busbars are essential for maximizing efficiency, safety, and performance in modern EV battery packs, drawing on our extensive experience in manufacturing and material science.

Table of Contents

The Evolution of Power Distribution: From Wire Harnesses to Rigid Busbars

In the early days of automotive design, round wire cables were the standard for electrical distribution. They were flexible, readily available, and sufficient for the low-voltage (12V) systems that powered lights, radios, and starters. However, the advent of the Electric Vehicle introduced a new set of demands that traditional cabling struggles to meet. Modern EVs operate at voltages ranging from 400V to 800V and beyond, carrying currents that can exceed hundreds of amperes during fast charging or rapid acceleration.

Under these conditions, traditional cabling presents significant limitations. The circular cross-section of a wire creates inefficient space utilization, and the bundling of cables can lead to heat entrapment. Furthermore, the chaotic nature of wire harnesses complicates automated assembly, increasing production time and the risk of human error.

The rigid busbar represents the engineered evolution of power distribution. By utilizing a solid, flat conductor—typically copper or aluminum—busbars offer a streamlined, efficient, and robust alternative. Unlike cables, which are often routed ad-hoc, rigid busbars are precision-engineered components designed to fit into specific geometries within the battery pack. This shift is not merely aesthetic; it is a fundamental upgrade in how energy flows from the cells to the inverter and motor.

For a deeper understanding of the history of electrical interconnects, the Institute of Electrical and Electronics Engineers (IEEE) provides extensive archives on power electronics evolution.

Defining the Rigid Busbar: Anatomy of Efficiency

To understand why rigid busbars optimize efficiency, we must first define what they are in the context of precision manufacturing. A rigid busbar is a pre-formed conductor, machined or stamped from sheet or coil stock. At JUMAI TECH, we specialize in fabricating these bars to exact tolerances, utilizing our expertise in precision stamping dies to create complex shapes that navigate the tight confines of a battery module.

The Geometry of Performance

The most defining characteristic of a busbar is its rectangular cross-section. This geometry is not arbitrary; it is crucial for minimizing the “skin effect.” In alternating current (AC) applications—and high-frequency switching environments found in EV inverters—current tends to flow along the surface of the conductor rather than through its center.

A flat busbar offers a significantly higher surface-area-to-cross-section ratio compared to a round cable of the equivalent gauge. This allows for better electron flow and lower AC resistance (impedance). Even in Direct Current (DC) applications typical of the battery pack itself, the flat shape aids in thermal management, which we will explore in the next section.

Material Purity

The efficiency of a rigid busbar begins at the molecular level. At JUMAI TECH, we primarily utilize Oxygen-Free Electronic (OFE) Copper (C10100) or Electrolytic Tough Pitch (ETP) Copper (C11000) for our premium busbars. These grades of copper boast an electrical conductivity rating of 100% to 101% IACS (International Annealed Copper Standard).

Using lower-grade alloys introduces resistance, which converts valuable battery energy into waste heat. In an EV, where every mile of range counts, the purity of the busbar material is non-negotiable.

Thermal Management: The Hidden Efficiency Booster

Heat is the enemy of battery performance and longevity. As current flows through a conductor, resistance generates heat—a phenomenon known as Joule heating. If this heat is not effectively dissipated, it can raise the temperature of the surrounding battery cells, leading to accelerated degradation or, in extreme cases, thermal runaway.

Superior Heat Dissipation

Rigid busbars act as excellent thermal pathways. Their flat, wide surfaces provide a large area for heat to radiate away or be conducted into a heat sink. In contrast, a round cable is thermally inefficient; the insulation wraps around the conductor, trapping heat inside the core.

When we design custom busbars at JUMAI TECH, we often simulate thermal loads to optimize the width and thickness of the bar. This ensures that the temperature rise remains within safe limits (typically <30°C rise) even under maximum load.

Table 1: Thermal Performance Comparison (Busbar vs. Cable)

The following table illustrates the theoretical performance difference between a standard 4/0 AWG cable and a copper busbar of equivalent cross-sectional area carrying 300 Amps.

| Feature | 4/0 AWG Cable | Copper Rigid Busbar (3mm x 25mm) | Impact on EV Efficiency |

| Cross-Sectional Area | ~107 mm² | 75 mm² | Busbars require less copper for similar performance. |

| Surface Area (per meter) | ~0.045 m² | ~0.056 m² | Busbars offer ~24% more cooling surface area. |

| Heat Dissipation | Poor (Insulation Traps Heat) | Excellent (Radiative & Conductive) | Busbars lower system temperature. |

| Current Density | Lower Capacity | Higher Capacity | Busbars handle power spikes (fast charging) better. |

Data estimates based on standard engineering practices for unventilated enclosures.

For more on thermal conductivity standards, refer to the Copper Development Association.

Space Optimization and Volumetric Efficiency

One of the most valuable resources in an Electric Vehicle is space. Engineers are constantly fighting to increase energy density—packing more kWh into the same physical footprint. Rigid busbars are a critical tool in winning this battle.

The Low Profile Advantage

Cables have a minimum bend radius that must be respected to prevent damage to the insulation and the conductor strands. This results in “loops” of wire that consume valuable air space within the battery pack. Rigid busbars, however, can be formed with tight, 90-degree bends using our advanced CNC bending and stamping die technologies.

We can design busbars that hug the contours of the battery modules, lie flat against the enclosure walls, or stack closely together with thin insulation layers. This low-profile nature allows battery designers to reduce the overall height of the battery pack, which translates to more cabin space for passengers or a lower center of gravity for better vehicle handling.

Integrated Design Features

Because JUMAI TECH specializes in deep-drawn components and stamping, we can integrate features directly into the rigid busbar that would otherwise require separate parts. For example, we can stamp rigid busbars with integrated pogo-pin receptacles, fuse clips, or threaded sensing terminals. This reduction in part count not only saves space but also reduces the weight of the assembly and minimizes the points of potential failure.

Structural Integrity: Surviving the Road Environment

Electric vehicles are subjected to harsh mechanical environments. Potholes, vibrations from the road, and the torque of acceleration create constant physical stress on internal components. A loose connection in a high-voltage system is a catastrophic failure mode, potentially leading to arcing.

Vibration Resistance

Rigid busbars offer superior mechanical rigidity compared to flexible cables. Once bolted or welded into place, a rigid busbar effectively becomes a structural element of the battery pack. It does not flop or chafe against other components during vehicle operation.

At JUMAI TECH, we verify the structural integrity of our designs using Finite Element Analysis (FEA) to simulate resonance frequencies. We ensure that the natural frequency of the busbar does not match the vibration frequency of the vehicle, preventing fatigue fractures over the vehicle’s lifespan.

Automated Assembly and Consistency

From a manufacturing standpoint, rigid busbars enable automation. Robots can easily pick and place a rigid component with high precision. Cables, being flexible and unpredictable, are notoriously difficult for robots to manipulate, often requiring manual labor. By using rigid busbars, EV manufacturers can increase production throughput and ensure that every connection is torqued to the exact specification, enhancing the overall reliability of the fleet.

Material Selection: Copper vs. Aluminum in Rigid Busbars

When customizing a rigid busbar solution, one of the first questions we address with our clients is material selection. While copper is the gold standard for conductivity, aluminum has gained traction due to weight constraints.

The Case for Copper

Copper is the undisputed king of conductivity. It allows for the smallest possible cross-section for a given current rating. In space-constrained applications where maximizing power density is the primary goal, copper is the choice. Furthermore, copper’s oxide is conductive (unlike aluminum oxide), which makes bolted connections more reliable over time without aggressive surface treatments.

The Case for Aluminum

Aluminum has roughly 61% of the conductivity of copper but only 30% of the density. This means that for a given current carrying capacity, an aluminum busbar will be larger physically but significantly lighter (about 50% lighter) than its copper counterpart. For EVs targeting maximum range, reducing weight is crucial.

However, aluminum requires specialized plating (typically nickel or tin) to prevent oxidation and galvanic corrosion when mating with copper terminals. At JUMAI TECH, we offer both materials, along with the necessary plating technologies to ensure long-term reliability.

Table 2: Material Comparison

| Property | Copper (ETP C11000) | Aluminum (6101-T6) |

| Conductivity (% IACS) | 101% | ~57% |

| Density (g/cm³) | 8.89 | 2.70 |

| Thermal Conductivity (W/m·K) | 390 | 220 |

| Tensile Strength (MPa) | 220-300 | 200-245 |

| Cost | High | Low |

For detailed material property standards, the ASTM International website is an invaluable resource.

The Role of Precision Stamping Dies in Busbar Manufacturing

This is where JUMAI TECH’s unique heritage sets us apart. Many suppliers simply cut and bend metal. We approach busbar manufacturing with the mindset of a precision stamping die maker.

Consistency at Scale

For mass production of EV battery packs, consistency is paramount. A deviation of just a few millimeters in a busbar’s bend can cause stress on the battery terminals, leading to cracks in the cell casing. We design and fabricate our own stamping dies in-house. This allows us to control the “spring-back” effect of the metal—the tendency of metal to return to its original shape after bending.

By compensating for spring-back within the die design, we ensure that every single rigid busbar that comes off our line is identical to the CAD model. This “Design for Manufacturing” (DFM) approach drastically reduces rejection rates during the client’s assembly process.

Complex Geometries and Deep Drawing

Some modern battery designs require busbars with three-dimensional topography—steps, indentations, or cup-like features to accommodate sensors or specific cell heights. Our expertise in deep-drawn components allows us to manipulate the metal in ways that standard bending cannot achieving. We can create rigid busbars that flow through the battery pack like a liquid, navigating obstacles while maintaining a solid electrical path.

Inductance and Electrical Noise Mitigation

As EV architectures move toward higher voltages (800V systems), the switching frequency of the inverters increases. This creates electromagnetic interference (EMI) and issues with inductance.

Minimizing Stray Inductance

Stray inductance in the DC link can cause voltage spikes that damage IGBTs or SiC MOSFETs in the inverter. Rigid busbars are ideal for minimizing this inductance. By utilizing a “laminated” busbar structure—where positive and negative rigid bars are stacked on top of each other with a thin dielectric layer in between—inductance is cancelled out.

The opposing magnetic fields generated by the current flowing in opposite directions effectively neutralize each other. This results in a “cleaner” power delivery system. While this article focuses on standard rigid busbars, it is important to note that JUMAI TECH also manufactures the constituent copper layers for laminated busbar systems, utilizing our high-precision cutting and stamping capabilities.

Insulation Technologies: Safety First

A rigid busbar is a live conductor carrying lethal voltages. Therefore, the insulation system is just as important as the metal itself. We employ several advanced insulation methods depending on the client’s specific requirements.

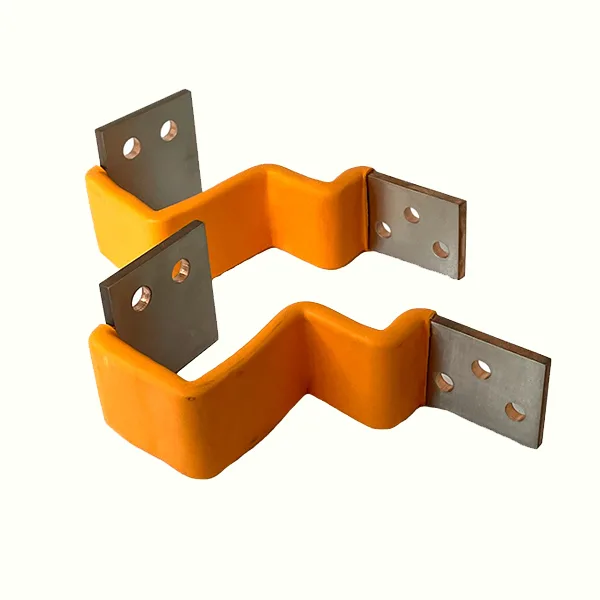

Powder Coating (Epoxy)

Epoxy powder coating is a popular choice for complex busbar shapes. The electrostatic process ensures that the insulation reaches every nook and cranny of the bar, providing a consistent dielectric strength. It is tough, resistant to chemicals, and offers excellent thermal cycling capability.

Heat Shrink Tubing

For simpler geometries, heat shrink tubing is a cost-effective solution. We use high-grade, automotive-rated tubing (often orange to signify high voltage) that resists abrasion and high temperatures.

Plastic Injection Molding

For the ultimate in structural integration, we can place the rigid busbar into a mold and inject plastic around it. This creates a fully insulated, structural part that can serve as a battery module cover. This requires high-precision alignment of the metal insert, a task perfectly suited to our background in precision dies and accessories.

Design for Manufacturability (DFM): Partnering with JUMAI TECH

One of the most common challenges we face is receiving a design from a client that works in simulation but is difficult or expensive to manufacture. This is why we encourage early engagement.

optimizing for Stamping and Bending

Our engineering team reviews client designs to identify “pain points.” For example, if a bend radius is too tight for the material thickness, it will cause cracking. If a hole is placed too close to an edge, it will deform during stamping.

By applying our DFM principles, we can often suggest slight geometry changes that maintain the electrical performance while significantly reducing tooling costs and lead times. We treat our clients as partners, leveraging our knowledge of Precision Copper Busbars to improve their product.

Rapid Prototyping

Before committing to hard tooling (expensive stamping dies), we utilize CNC wire cutting and soft tooling methods to produce prototype batches. This allows our clients to physically install the busbars in their prototype battery packs, verifying fit and function before mass production begins.

Future Trends: High Voltage and Fast Charging

The EV industry is currently shifting from 400V architectures to 800V architectures. This shift allows for faster charging times (adding 200 miles of range in 15 minutes) but places new demands on busbars.

Thermal Shock Management

Fast charging dumps massive amounts of energy into the battery in a short time, causing rapid thermal spikes. Rigid busbars must be designed with enough thermal mass to absorb this spike without overheating the insulation.

Partial Discharge (Corona)

At higher voltages, the risk of partial discharge (micro-arcs within the insulation) increases. This can slowly erode the insulation over time. JUMAI TECH is actively researching and implementing advanced insulation materials with higher PDIV (Partial Discharge Inception Voltage) ratings to future-proof our components for the next generation of hyper-cars and heavy-duty electric trucks.

Conclusion: The Backbone of the Electric Future

The rigid busbar is more than just a piece of copper; it is the backbone of the modern EV battery pack. It solves the complex challenges of thermal management, spatial constraints, vibration resistance, and electrical efficiency that wire harnesses simply cannot address.

At JUMAI TECH (www.deepdrawtech.com), we are not just manufacturers; we are innovators in the field of Precision Copper Busbars, Deep-Drawn Components, and Precision Stamping Dies. We understand that as the world moves toward a greener future, the quality of the components we produce directly impacts the efficiency and reliability of that future.

Whether you are designing a compact urban commuter EV or a high-performance electric truck, our team is ready to provide the custom rigid busbar solutions you need. We invite you to contact our engineering team today to discuss how we can help you maximize the efficiency of your battery pack designs. Let us turn your complex electrical challenges into streamlined, precision-engineered realities.