Battery enclosures have become one of the most demanding “metal box” applications in modern manufacturing. They must protect high-energy cells, survive vibration and corrosion, manage heat, and still be cost-effective at volume. A well-designed deep drawn box is often the simplest way to hit those goals—because it replaces complex welded fabrications with a single, repeatable, high-integrity formed shell.

At JUMAI TECH (deepdrawtech.com), we build custom deep-drawn components, precision stamping dies, and high-precision copper parts for global OEMs. In this guide, we’ll explain how to choose the right deep drawn box solution for battery enclosures—using clear language, practical design rules, and a “what matters on the factory floor” mindset.

Table of Contents

What “deep drawn box” really means in battery enclosure projects

Deep drawing in one sentence

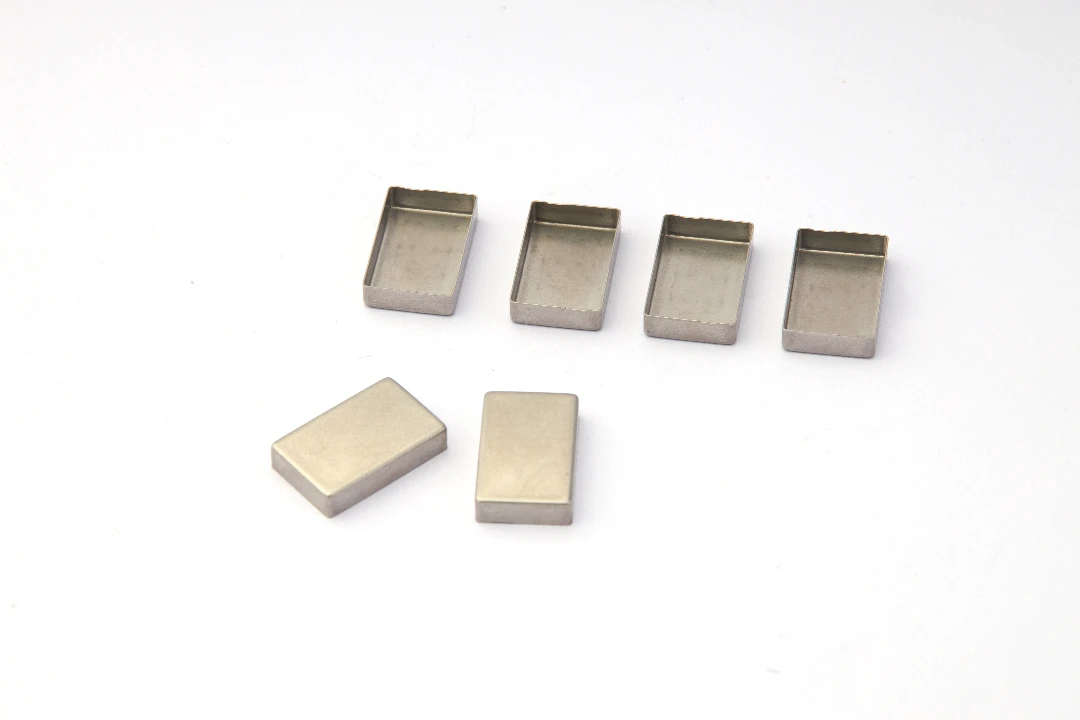

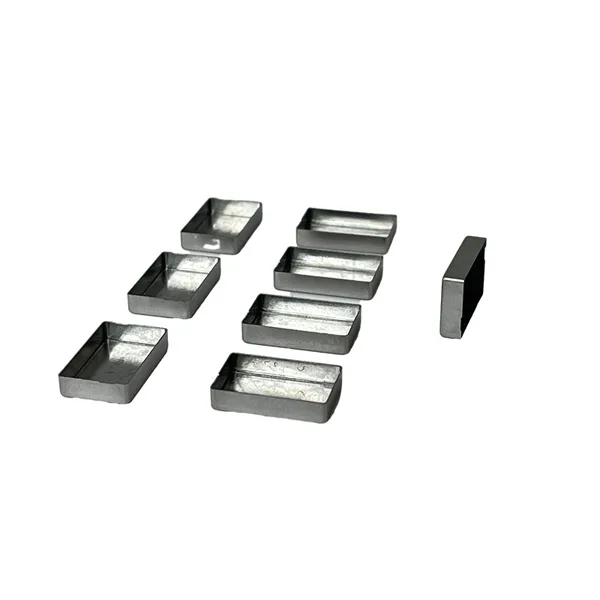

Deep drawing is a forming process that pulls a flat blank into a die cavity to create a cup- or box-like shape with controlled wall thickness and consistent geometry. For battery projects, the result is a deep drawn box that can act as a housing, cover, shield, or structural shell with fewer joints and fewer leak paths.

Why this process fits battery enclosures so well

Battery enclosures are unforgiving to weak seams and inconsistent geometry. A deep drawn box starts with continuity of material, so it naturally resists crack initiation at weld toes and reduces the number of places where water, electrolyte vapor, or road salt can penetrate. It also gives you a stable foundation for adding flanges, sealing grooves, bosses, and stiffening features in downstream operations.

Where deep drawn boxes show up in battery systems

A deep drawn box can be used for module cans, electronics housings, junction boxes, sensor housings, shielding covers, vent assemblies, and protective sub-enclosures inside the pack. In many architectures, multiple deep-drawn shells combine with stamped brackets and busbar systems to create a complete, assembly-friendly enclosure strategy.

What battery enclosures must survive in the real world

Mechanical loads: vibration, shock, and crash transfer

Battery packs see constant vibration, occasional impact, and high transient loads during harsh events. Even when the pack is “inside” the vehicle or ESS cabinet, energy travels through mounts and fasteners into the enclosure. A deep drawn box with well-planned ribs, bead features, and flange geometry can keep stiffness high without excessive weight.

Environmental exposure: salt, humidity, chemicals, and dust

Road vehicles face salt spray, water jets, pressure washing, and chemical exposure from cleaners and coolants. Stationary systems face humidity, temperature swings, and airborne contamination. Enclosure design typically targets defined protection levels (often discussed using IP ratings), which are standardized under IEC guidance for enclosure ingress protection. iec.ch

Thermal behavior: heat in normal use and heat in abnormal events

Normal operation creates heat from cell internal resistance and power electronics. Abnormal events can include localized overheating and, in worst cases, thermal runaway propagation. Your enclosure strategy has to support thermal pathways, insulation, venting logic, and safe containment—without forcing the entire pack to become heavy, overbuilt, or impossible to assemble.

Why choose a deep drawn box over a welded fabrication

Fewer seams, fewer leak paths, fewer surprises

Every seam is a potential failure mode: distortion, porosity, micro-cracking, and inconsistent flatness that fights your gasket. A deep drawn box reduces the seam count dramatically, which usually improves sealing repeatability and reduces inspection burden. When a design team is chasing IP performance and consistent torque retention, this advantage is hard to ignore.

Better dimensional consistency at volume

Deep drawing is tool-driven, so once the die is stable, the part-to-part repeatability is excellent. That consistency matters when your enclosure interfaces with automated dispense, robotic handling, gasket placement, or lid welding. It also simplifies downstream stamping or trimming operations because the part datum scheme stays stable.

Weight and material efficiency

Welded assemblies often need extra flanges, overlap regions, and reinforcement plates. A deep drawn box can integrate stiffness features into the shell itself, reducing part count and allowing thinner gauge in non-critical regions. In EV and mobility applications, “grams saved” is not marketing—those grams convert into range, payload, or cost.

Material selection for deep drawn box battery enclosures

Aluminum alloys: lightweight and corrosion-friendly

Aluminum is popular where weight matters and corrosion exposure is high. The right alloy choice and temper control help you balance formability, strength, and springback. For a deep drawn box, we typically guide customers toward alloys known for drawability, then tune the geometry and draw sequence to reduce wrinkling and tearing.

Stainless steel: strength, heat tolerance, and robust durability

Stainless can be a strong choice for harsh environments and high temperature tolerance. It also performs well where puncture resistance and durability dominate the design priorities. The trade-off is forming load, tool wear, and cost—so design-for-drawing becomes even more important.

Low-carbon steel with coatings: cost-effective with the right protection

Coated steels can deliver cost advantages and solid mechanical behavior. If your enclosure will be coated, plated, or e-coated after forming, you can achieve strong corrosion performance while keeping tooling and part cost competitive. The key is aligning coating choices with sealing surfaces, electrical grounding points, and assembly processes.

Copper and copper alloys: special cases inside the enclosure

Copper is typically not the main enclosure shell material due to cost and density, but it appears frequently as integrated shielding elements, thermal spreaders, and high-current interconnect components. When a project includes both enclosure parts and current-carrying hardware, JUMAI TECH can support the mechanical shell (deep drawn box) and the electrical system (precision copper busbars) as a coordinated solution.

Design rules that make a deep drawn box manufacturable

Start with draw depth, corner radii, and wall transitions

Deep drawing rewards smooth geometry. Generous corner radii reduce tearing risk and help material flow uniformly, while controlled transitions prevent thinning spikes. If you need sharp internal corners for packaging reasons, we usually recommend a staged approach (draw + re-draw + calibration) rather than forcing sharpness in one hit.

Plan flanges and sealing surfaces like an assembly engineer

A sealing flange must be flat enough for gasket compression and robust enough to hold torque without “oil canning.” That means you should design flange width, bead features, and fastener pitch together, not separately. A deep drawn box can support excellent sealing performance, but only if the flange is treated as a functional surface—not just an outline.

Add stiffness with beads and ribs instead of thickness

If you increase thickness to fix stiffness, you pay for it forever (material cost, forming tonnage, weight, and sometimes cooling penalties). Beads, ribs, and local emboss features are often a better stiffness strategy. They can also improve noise and vibration behavior by raising panel natural frequencies.

Decide early: one-piece shell, two shells, or shell + lid

Some enclosure architectures want a deep drawn box plus a stamped or machined lid. Others want two deep-drawn halves joined by laser welding, clinching, or fasteners. The “right” choice depends on serviceability targets, sealing method, and how you plan to route cables, vents, and thermal interfaces.

Sealing strategy and IP protection: designing for leak-tight performance

What IP discussions mean for enclosure designers

In many programs, “IP level” becomes shorthand for dust and water resistance. The IEC explains how IP ratings relate to enclosure resistance against dust and liquid intrusion, and this is often the language used across global supply chains. iec.ch

How deep drawn boxes help sealing

A deep drawn box gives you a continuous wall that naturally reduces leak paths. It also improves the repeatability of gasket compression because fewer welded distortions exist near the seal. When your sealing is consistent, your validation testing becomes more predictable, and you can reduce rework loops late in the program.

Practical sealing details that matter

Sealing success often comes down to mundane details: surface finish, flange flatness, gasket groove design, and fastener torque consistency. It also depends on how the enclosure will be assembled at line speed, with real operators and real tolerances. We recommend designing a sealing “stack-up” that still works when every dimension is at its tolerance edge.

Thermal and electrical considerations that influence deep drawn box design

Heat flow: don’t treat the enclosure as “just a box”

Enclosures can be part of your thermal system. A deep drawn box can provide controlled contact surfaces for thermal pads, heat spreaders, and conduction paths to cooling plates. If you design those interfaces early, you can avoid late-stage add-ons that increase cost and complicate assembly.

Isolation, grounding, and EMI control

Battery systems mix high voltage, sensitive sensing, and noisy switching electronics. Enclosure design often needs well-defined grounding points, reliable electrical bonds, and shielding continuity. Deep drawn metal shells are helpful here, especially when you maintain consistent surface contact zones and avoid coatings that block conductivity in critical areas.

Venting and abnormal event behavior

Venting design is a system-level decision, but the enclosure geometry must support it. A deep drawn box can integrate vent ports, reinforcement around vent regions, and protective features that guide gas flow. The goal is controlled behavior, not simply “making a hole,” and it should be validated with the full pack architecture.

Tooling and process choices that shape quality and cost

Die design is where repeatability is born

Deep drawing success depends on blank holding, draw beads, lubrication strategy, and stage planning. When these are engineered correctly, you get stable wall thickness, minimized wrinkling, and predictable springback. The best programs treat the stamping die as a precision asset, not an expense to minimize.

Prototype path vs. mass production path

For early prototypes, you may accept simplified tooling to get parts quickly. For scale, you want robust dies, stable trimming, and measured tool wear behavior. A good supplier will design the prototype path so it doesn’t force a full redesign when you move to higher volumes.

Secondary operations: trimming, piercing, forming, joining

Battery enclosures rarely end at “the draw.” Most deep drawn box parts need trimming, windows, cable pass-throughs, bracket features, and joining interfaces. We plan these steps as a coherent process route so you avoid distortion from late-stage piercing or excessive handling.

Surface protection and finishing options for battery enclosure shells

Coatings and treatments must match your sealing and grounding needs

Corrosion protection is essential, but coatings can interfere with grounding continuity or gasket friction behavior. The right choice depends on where you need conductivity, where you need low friction for assembly, and where you need maximum corrosion resistance. We often recommend masking or local surface preparation in bond zones to keep both corrosion and electrical performance under control.

Appearance and branding considerations

Not every battery enclosure needs to look pretty, but many customer-facing ESS products do. Texture, gloss, laser marking, and consistent surface tone can be important for brand perception. Deep drawn shells can deliver a clean, uniform appearance because they avoid heavy weld scars and grinding marks.

Durability in service and serviceability in the field

A finish is only “good” if it survives real-world handling, thermal cycling, and service interventions. If your program requires maintenance access, fastener re-torque, or lid removal, the surface system should be chosen to avoid galling, flaking, or corrosion creep at the edges.

Validation and compliance: what standards influence enclosure choices

Transport and shipping: UN 38.3 is part of the compliance landscape

If you ship lithium cells or batteries, your program often references UN testing guidance for classification and transport readiness. UN Manual of Tests and Criteria subsection 38.3 is widely recognized in global logistics discussions for lithium batteries. UNECE

Vehicle-level or system-level regulations: UNECE R100 is often referenced

For many EV programs, safety requirements can reference UNECE regulations around the electric powertrain and rechargeable energy storage systems. UNECE Regulation No. 100 is one of the key references seen in international compliance conversations. UNECE

Safety testing standards: UL 2580 and abuse evaluation discussions

In North America-facing programs, UL standards are frequently part of the testing and certification plan. UL 2580 is specifically framed around evaluating safety of batteries for use in electric vehicles under simulated abuse conditions, which can influence enclosure integrity targets and venting strategies. Shop UL Standards

Environmental validation: ISO 16750 is common language for stresses and tests

Many OEMs speak ISO 16750 when they talk about environmental stresses and recommended tests for vehicle electrical/electronic equipment. Even when your deep drawn box is a “mechanical” part, it must survive the environment that ISO 16750 describes, especially if it interacts with electrical systems. ISO

Industrial and stationary systems: IEC 62619 is frequently used in safety planning

For industrial and stationary lithium battery applications, IEC 62619 is often referenced as it specifies requirements and tests for safe operation of secondary lithium cells and batteries in industrial contexts. Your enclosure decisions can either simplify or complicate how the full system meets those safety expectations. IEC Webstore

To explore these references directly, you can review: UN 38.3 guidance, UNECE R100, UL 2580 overview, ISO 16750, IEC 62619, and IEC IP ratings. These links help teams align terminology, but your final compliance plan should always be confirmed with your certification and regulatory stakeholders.

A practical checklist for choosing the right deep drawn box solution

1) Define the function before the geometry

Start by stating what the enclosure must do: protect, seal, stiffen, shield, conduct heat, or support mounting. Then translate those functions into measurable targets like stiffness, flatness, leak rate targets, mass, and assembly time. This prevents “pretty CAD” that becomes costly or unstable in production.

2) Choose the process route, not just the part shape

A deep drawn box may be a single draw, a multi-stage draw, a draw plus ironing, or a deep-drawn shell with secondary forming. Each path has different tooling cost, cycle time, and risk profile. When you pick the route early, you avoid late engineering changes that disrupt validation schedules.

3) Align tolerances with what deep drawing can do best

Deep drawing excels at repeatable overall shape and consistent walls, especially at volume. It is less ideal for ultra-tight positional tolerances on complex hole patterns unless you plan the trimming and piercing strategy carefully. The best programs define realistic tolerances, then use datums that match the forming process.

4) Validate sealing and joining with realistic samples

Sealing rarely fails because of one giant mistake; it fails because of several small stack-ups. Build samples that include real finishes, real fasteners, and real gasket materials, and test them under thermal cycling and vibration. When you do this early, deep drawn box solutions become a predictable choice instead of a risky one.

Why JUMAI TECH for deep drawn box battery enclosure components

Engineering-first support: DFM that saves time and money

We treat DFM as a shared engineering task, not a quote attachment. Our team reviews draw depth, radii, flange strategy, trimming approach, and joining interfaces so the part is stable in production and friendly to assembly. That approach typically reduces tooling iterations and helps customers hit SOP targets with fewer surprises.

Tooling capability: precision stamping dies built for repeatable forming

Deep drawn box quality depends on die quality. We design and build precision tooling with a focus on repeatability, wear management, and process stability across long production runs. If your program needs controlled dimensional behavior over time, robust tooling strategy is non-negotiable.

One supplier, coordinated parts: deep-drawn shells + stamping + copper solutions

Battery systems often combine enclosure parts with brackets, shields, and high-current interconnects. JUMAI TECH’s scope—deep-drawn components, precision stamping, and precision copper busbar capability—helps you reduce supplier complexity and align mechanical and electrical integration earlier.

Quality mindset: built for OEM expectations

Battery enclosure programs typically demand structured inspection plans, consistent material traceability, and validation support. We build those expectations into our project workflows because we’ve lived the realities of OEM launches. When the schedule tightens, disciplined manufacturing becomes the difference between “almost ready” and “shipping parts.”

Choose a deep drawn box that supports the whole battery system

A battery enclosure is not only a protective shell—it is part of the safety, thermal, electrical, and assembly system. The right deep drawn box solution reduces seams, increases repeatability, improves sealing behavior, and supports scalable manufacturing. When you combine strong DFM, the right materials, and a stable forming process, deep drawing becomes one of the most reliable routes to high-performance battery enclosure components.

If you’re evaluating a deep drawn box for a battery enclosure—EV, ESS, or industrial—JUMAI TECH can support you from concept review and prototype tooling through mass production. Share your target dimensions, material preference, sealing strategy, and volume forecast, and we’ll recommend a manufacturable process route that fits both performance and cost.