If you’re designing a sensor that must survive moisture, pressure cycling, oils, fuels, salt spray, washdown chemicals, or even vacuum environments, the housing is not “just a shell.” A truly reliable package often starts with deep drawn metal stamping—because leak paths usually come from seams, stacked tolerances, and inconsistent forming, not from the sensor element itself. In this guide, you’ll learn how deep drawn metal stamping helps create leak-tight sensor housings that scale cleanly from prototypes to high-volume production.

Table of Contents

Why Leak-Tight Sensor Housings Demand Better Metal Forming

What “leak-tight” really means in sensor packaging

“Leak-tight” can mean different things depending on the industry and the medium you are sealing against. For some applications it means preventing liquid ingress during washdown, while others require hermeticity verified by tracer-gas methods and strict acceptance limits. Standards and test methods such as MIL-STD-883 (Method 1014: Seal) are widely referenced in high-reliability electronics packaging, and they illustrate how seriously the industry treats leak performance and verification (MIL-STD-883 PDF).

Where leaks come from in conventional housings

Many leaks are not caused by “bad seals,” but by geometry that makes sealing inconsistent. Machined parts with sharp transitions, welded tubes with imperfect fit-up, and assemblies with multiple joints all increase the number of possible leak paths. Deep drawn metal stamping reduces those risk points by forming a near-seamless body, which often means fewer joints to qualify and fewer interfaces to control.

What Makes Deep Drawn Metal Stamping Different

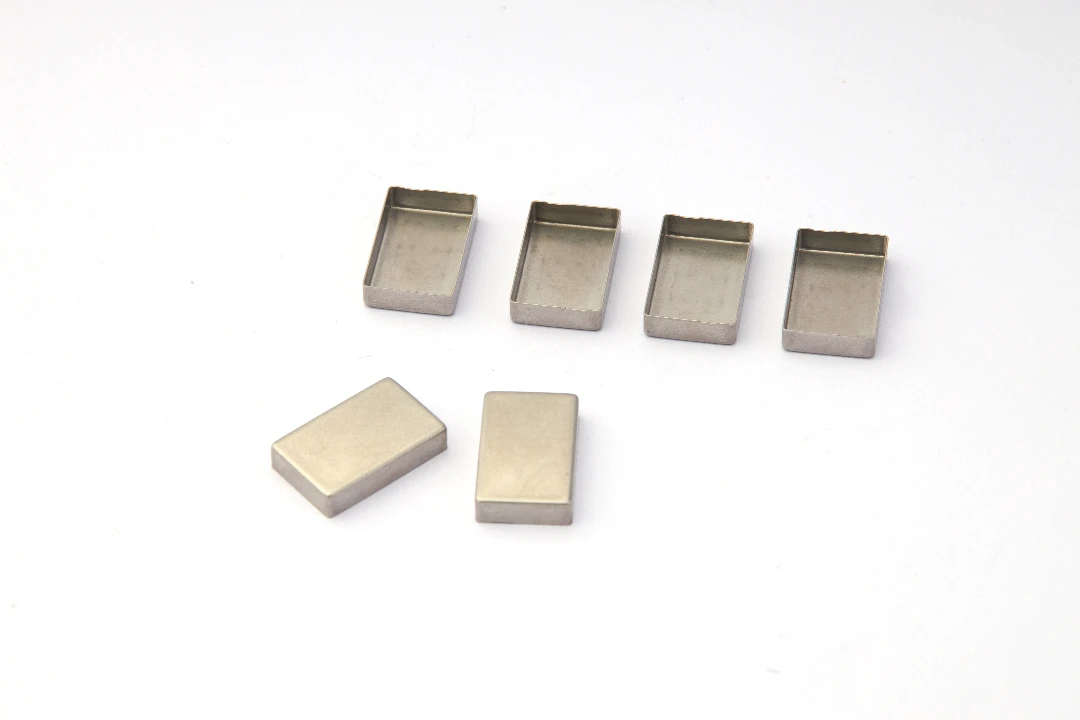

Seamless geometry: fewer joints, fewer leak paths

Deep drawn metal stamping forms cups, cans, and shells from sheet metal with a punch-and-die action, producing a continuous wall without a longitudinal seam. When the housing body is seamless, your sealing strategy becomes simpler—because you’re no longer compensating for a seam line, weld mismatch, or tube ovality. This is especially valuable for compact sensor packages where you have limited sealing land and minimal tolerance budget.

Consistent wall thickness for predictable sealing

A well-controlled deep drawing process can produce a wall thickness profile that is stable and repeatable, making it easier to design weld joints, crimp features, and O-ring glands. For many sensor housings, predictable wall behavior matters as much as absolute thickness, because sealing depends on uniform contact pressure and consistent deformation. Technical overviews of deep drawing often emphasize that the process forms a recessed part with thickness largely related to the original blank (with exceptions like ironing), which is a key advantage for repeatability (Deep drawing overview).

Repeatability at scale (the real cost saver)

Leak-tight performance is not only about passing one test—it’s about passing every time, across shifts, lots, and production ramps. Deep drawn metal stamping is inherently suited for repeatable high-volume manufacturing when tooling, lubrication, and press controls are stable. That repeatability reduces your total cost of quality by preventing rework loops like “weld tweak → retest → rework” that often appear when the base geometry is inconsistent.

How the Deep Drawn Metal Stamping Process Works

Blanking, first draw, redraw, and ironing

Most deep drawn housings begin with blanking a flat disc, followed by a first draw into a cup shape. For deeper housings, redraw operations progressively increase depth and refine wall geometry, while ironing can be used to control wall thickness and improve surface uniformity. These stages help designers achieve the length-to-diameter ratios that are hard to reach with “simple stamping” alone.

Controlling friction, lubrication, and draw beads

Leak-tight parts require smooth, stable metal flow to avoid micro-cracks, thinning, or surface damage that can later become leak-related defects. Process details like lubricant selection, blank-holder force, and draw-bead geometry heavily influence wrinkling and tearing risk. When deep drawn metal stamping is done correctly, it produces surfaces and transitions that support consistent joining and sealing operations downstream.

Heat treatment and annealing between draws

Some materials work harden quickly and may require intermediate annealing to maintain ductility through multiple draws. This matters for leak-tight housings because the worst failures are often subtle: tiny cracks, grain-boundary issues, or high residual stress that shows up only after pressure cycling. A disciplined draw + anneal strategy supports both formability and long-term stability in the finished sensor package.

Material Choices for Leak-Tight Housings

Stainless steels: 304L/316L and corrosion resistance

For many industrial and automotive sensors, stainless steel is the default because it balances corrosion resistance, weldability, and cost. Low-carbon variants (like “L” grades) are often selected to reduce sensitization risk in welded zones, which can matter when the sealing joint is near a corrosive environment. Deep drawn metal stamping in stainless is a proven approach for rugged shells that need both mechanical integrity and stable sealing interfaces.

Nickel alloys, titanium, and specialty materials

Harsh environments—high temperature, aggressive chemicals, or extreme corrosion—often push designs toward nickel-based alloys or titanium. These materials can be more demanding to form and join, which makes process control even more important. If your application involves vacuum compatibility, outgassing, or space-grade material selection, NASA’s materials engineering resources and outgassing references can be helpful for early screening and documentation (NASA GSFC Outgassing Database).

Copper and copper alloys when conductivity matters

While sensor housings are often stainless or nickel alloy, some designs integrate copper-based features for thermal or electrical reasons, especially where the housing also acts as a conductor or heat spreader. Copper’s electrical properties are extensively characterized in the literature, including NIST publications that document resistivity behavior across temperature ranges (NIST copper resistivity reference). When copper alloys appear in your sensor packaging stack, deep drawn metal stamping can still be viable—with proper tooling, lubrication, and surface protection planning.

Design Rules That Improve Leak-Tight Performance

Radii, draw ratio, and wall transitions

Deep drawn housings like gentle transitions because sharp radii concentrate strain and can thin the wall locally. When wall thinning becomes inconsistent, sealing features (like weld lands or crimp grooves) lose predictability. A design that respects draw-friendly radii typically improves both yield and long-term leak performance.

Flanges, sealing lands, and weld-fit geometry

Many leak-tight sensor housings rely on a flange for laser welding, resistance welding, brazing, or crimp sealing. The best flange designs don’t just “exist”—they provide enough width for stable fixturing, enough thickness for energy input consistency, and enough flatness to avoid micro-gaps. Deep drawn metal stamping helps here by forming the body as one piece, so your flange-to-wall transition is controlled rather than assembled.

Tolerances, surface finish, and plating considerations

Leak-tight designs should treat tolerance as a system, not a number on a print. Surface finish, waviness, and micro-scratches can affect sealing performance as much as diameter tolerance, especially for elastomer seals and crimp joints. If plating or coating is required, it must be selected with the joining method in mind, because some coatings influence weld stability and long-term corrosion behavior.

Tooling and Process Control: Where Quality Is Actually Made

Die design for stable material flow

Tooling is not only about shape—it’s about controlling how the metal flows under load. Draw beads, entry radii, and punch/die clearances determine whether the part forms smoothly or accumulates hidden strain. For leak-tight housings, that “invisible” strain can later show up as distortion, springback drift, or micro-cracking after assembly operations.

Measurement, SPC, and traceability

If the housing must pass leak tests repeatedly, you need consistent geometry that holds across lots. That means measuring critical features (seal lands, port diameters, flange flatness, wall thickness zones) and monitoring them with SPC where appropriate. A disciplined quality plan makes deep drawn metal stamping a platform for stable production, rather than a “trial-and-error” forming task.

Cleanliness and controlled environments

Particles and residues can create sealing failures even when dimensions are perfect. If your assembly requires controlled cleanliness—especially for medical, optics, or sensitive MEMS packaging—cleanroom classification standards like ISO 14644-1 provide a common language for environment requirements and documentation (ISO 14644-1 standard page). Designing the manufacturing flow to protect seal surfaces is often as important as the forming step itself.

Secondary Operations That Complete the Housing

Trimming, piercing, and forming ports

Most sensor housings need secondary operations: trimming to final length, piercing for vent holes or ports, and reforming flanges for joining. These steps must be planned so they don’t distort sealing features or introduce burrs that interfere with assembly. When deep drawn metal stamping is paired with the right secondary process plan, the final housing stays stable and seal-ready.

Laser welding, brazing, and joining strategies

Leak-tight housings often combine deep drawn shells with end caps, feedthroughs, diaphragms, or threaded bosses. Joining choices should match the performance target, and verification requirements should be defined early so you don’t “discover” leak testing constraints after the design is frozen. Many hermetic verification approaches reference helium tracer methods and acceptance frameworks used across aerospace and military supply chains.

Outgassing and vacuum considerations (when applicable)

If your sensor housing will operate in vacuum or space-adjacent environments, material selection and process residues matter. NASA’s guidance references outgassing testing aligned with ASTM E595, which helps teams screen materials and document suitability (NASA outgassing notes; ASTM E595 standard page). Even if you’re not building spacecraft hardware, these references can strengthen your material and cleanliness rationale.

Verification: Proving the Housing Is Leak-Tight

Helium mass spectrometer leak detection

Helium leak testing is a common method for high-sensitivity leak detection because helium is inert and easy to detect at very low leak rates. Standards like ASTM E498 describe procedures for leak testing using a mass spectrometer leak detector or residual gas analyzer, and they help unify terminology and method expectations across suppliers and OEMs (ASTM E498 overview). Using a recognized method also makes supplier qualification and customer audits smoother.

Hermetic seal standards and acceptance limits

For hermetic packages with internal cavities, MIL-STD-883 Method 1014 is frequently referenced for seal testing concepts and procedures in microelectronics-style packages (MIL-STD-883 PDF). In many industries, acceptance limits and test setups are tailored to package volume, application risk, and service environment, so it’s important to align requirements early. Practical industry notes on hermetic connector leak-rate limits also highlight how test methods map to real qualification expectations (Hermetic leak-rate testing note (PDF)).

Functional testing: pressure cycling, burst, and real-world abuse

Leak tests are vital, but functional reliability often requires more—pressure cycle testing, thermal shock, vibration, and corrosion exposure. Deep drawn metal stamping supports these tests because the seamless shell typically handles stress more uniformly than multi-piece constructions. When the housing is structurally stable, seals are less likely to “walk” under cycling, which is a common failure mode in compact sensor assemblies.

Typical Applications for Deep Drawn Leak-Tight Sensor Housings

Automotive and EV sensors

Under-hood sensors face temperature swings, oils, fuels, brake fluid, road salts, and vibration. Deep drawn metal stamping supports compact, durable shells for pressure, temperature, and fluid sensors where consistent sealing is critical over long service life. A seamless housing body also simplifies joining strategies that must hold up to mass production and aggressive validation cycles.

Industrial and process instrumentation

Industrial sensors often live in environments that punish weak seals: washdown, chemical exposure, and pressure transients. Deep drawn metal stamping can produce housings that are both mechanically robust and cost-effective at scale, making it easier to standardize designs across product families. For OEMs, the combination of repeatability and fewer leak paths often translates to fewer field failures and less warranty risk.

Medical, aerospace, and high-reliability devices

Medical and aerospace-style designs often require stronger documentation, cleanliness discipline, and conservative verification plans. Deep drawn metal stamping provides a strong foundation because it reduces assembly complexity at the housing level. When requirements extend to vacuum compatibility, material screening resources like NASA’s outgassing database can also support qualification documentation (NASA GSFC Outgassing Database).

Partnering with JUMAI TECH: From DFM to Mass Production

Fast iteration without surprises

Leak-tight performance should be designed in, not “tested in.” At JUMAI TECH, we treat deep drawn metal stamping as an engineering process—linking part geometry, material behavior, tooling design, and verification planning from the start. That approach helps you reach stable prototypes faster and reduces redesign cycles caused by late-stage leak failures.

Documentation that works for global OEM supply chains

Modern OEM programs expect clear drawings, controlled revisions, measurable CTQs, and consistent inspection methods. When you align deep drawing process controls with leak verification methods like helium testing frameworks, you get fewer supplier disputes and faster approvals. The result is a housing you can scale confidently, not a part that only works in small batches.

What to send for a fast, accurate quote

To move quickly, prepare a drawing (or 3D model), target material, annual volume, and the leak-tight requirement (washdown level, pressure rating, or hermetic test method). If you already have a preferred test approach, referencing standards like ASTM E498 and/or MIL-STD-883 Method 1014 helps everyone align on expectations early (ASTM E498 overview; MIL-STD-883 PDF). With that clarity, deep drawn metal stamping becomes a predictable path to a leak-tight sensor housing—rather than a trial-and-error effort.

Conclusion: Every Leak-Tight Housing Starts with the Right Form

When your sensor must survive real-world abuse, the housing must be more than “metal around electronics.” Deep drawn metal stamping reduces leak paths, improves geometry consistency, and supports repeatable joining and verification methods—making it one of the most practical foundations for leak-tight sensor housings. If you want a housing design that scales cleanly from prototype validation to stable production, JUMAI TECH is ready to help you engineer the deep drawn solution that fits your performance target, your cost target, and your qualification plan.

FAQ

What is deep drawn metal stamping?

Deep drawn metal stamping is a manufacturing process that shapes flat metal sheets into hollow shapes, like cups and cans, using a punch and die. This method creates seamless parts with consistent wall thickness, making them strong and reducing the chances of leaks, which is essential for items like sensor housings that need to keep out moisture and other elements.

Why are leak-tight sensor housings important?

Leak-tight sensor housings are crucial because they protect sensitive electronic components from moisture, chemicals, and pressure. If a housing is not leak-tight, the internal parts can get damaged, leading to failures. This is why making them right from the start with processes like deep drawn metal stamping is so important.

How does deep drawn metal stamping help prevent leaks?

Deep drawn metal stamping produces parts with fewer joints and seams, which are common sources of leaks. By creating a seamless body, the process reduces potential leak paths, making the housings more reliable and easier to seal effectively against harmful factors like water or dust.

What materials can be used for leak-tight housings?

Common materials for leak-tight housings include stainless steel, which offers good corrosion resistance, and sometimes nickel alloys or titanium for harsher environments. The choice of material depends on the conditions the sensor will face, such as exposure to chemicals, high pressure, or temperature variations.

How is the performance of a leak-tight housing tested?

Leak-tight housings are often tested using methods like helium leak detection, where helium is introduced into the housing and then measured to see if any escapes. This test is sensitive and can detect very small leaks, ensuring the housing is safe for use in demanding environments.

What design considerations improve leak-tight performance?

To enhance leak-tight performance, designers should use gentle radii for transitions and ensure that flanges are appropriately wide and flat. Attention to tolerances and surface finishes is also critical since imperfections can lead to weak sealing points.

Can deep drawn metal stamping work for high-volume production?

Yes, deep drawn metal stamping is ideally suited for high-volume production due to its repeatable nature. This means that once the process is set up correctly, manufacturers can produce thousands of identical parts with consistent quality, reducing costs and improving efficiency.

What are secondary operations in the context of sensor housings?

Secondary operations are additional processes needed after the deep drawn metal stamping. These may include trimming the parts to size, creating openings (like vents), and welding or joining various components together, all of which are important for achieving the final product.

What should I provide to get a quote for deep drawn metal stamping?

To obtain a quote, you should provide a drawing or 3D model of the part you need, the target material, the expected production volume, and any specific requirements for leak-tightness or testing methods. This information helps manufacturers give you an accurate and prompt response.

Why choose JUMAI TECH for manufacturing sensor housings?

JUMAI TECH specializes in deep drawn metal stamping and focuses on engineering processes that ensure quality and performance. They are equipped to handle everything from design to mass production, aiming to produce reliable and leak-tight sensor housings tailored to your needs.