When your program depends on millions of copper components—busbar elements, caps, cups, terminals, shields, housings, or battery current-path parts—you need a forming process that is fast, repeatable, and design-friendly. Deep drawn stamping is one of the most efficient ways to turn copper sheet/strip into robust 3D geometries with consistent wall thickness and excellent material utilization. At JUMAI TECH, we combine high-volume stamping expertise with deep-draw know-how to help OEMs and Tier suppliers scale copper parts without sacrificing electrical performance or dimensional stability.

Copper is an outstanding conductor, but it also introduces challenges in forming: work hardening, surface sensitivity, and tight tolerance expectations. With the right die design, press strategy, lubrication, and in-process controls, deep drawn stamping can deliver leak-tight, burr-controlled, cosmetically clean copper parts at production rates that match modern electrification and electronics demand.

Table of Contents

Why Deep Drawn Stamping Works So Well for Copper in High Volume

High throughput with coil-fed efficiency

For high-volume programs, coil-fed stamping is a proven manufacturing backbone. By running copper strip through progressive or transfer tooling, deep drawn stamping can create multiple formed features, trim profiles, and piercings in one continuous workflow. That means fewer touches, less handling damage, and predictable cycle times that scale.

Stronger parts through grain flow and formed geometry

Deep drawing reshapes copper while keeping the material continuous—often improving robustness compared to assemblies made from multiple pieces. When the draw direction and radii are engineered correctly, the formed geometry can enhance stiffness and vibration resistance while maintaining a stable current path. This is especially valuable for EV/ESS power distribution and high-current electronics where mechanical integrity and conductivity matter together.

Material utilization and cost control

Copper is not a “cheap” metal, so yield matters. Deep drawn stamping can reduce scrap versus machining-from-solid for many cup-like or shell-like shapes, and it can eliminate secondary joining steps that add labor and quality risk. When your annual volume is high, small gains in blank nesting, strip layout, and rework reduction can translate into big savings.

Copper Material Choices That Matter in Deep Drawn Stamping

Common copper grades and what they mean for forming

Material selection is the first lever for consistent deep drawn stamping. Many high-volume copper parts start with widely used grades such as C11000 (ETP copper) or oxygen-free variants when conductivity and cleanliness are critical. Copper properties and recommended application guidance are well summarized by the Copper Development Association (CDA) resources at copper.org, which can help buyers align grade selection with electrical and mechanical needs.

Standards and specs buyers reference most

High-volume projects often need a clear standard baseline for sheet/strip or alloy strip. Depending on the grade and form, buyers may reference ASTM standards (for example, copper and copper-alloy sheet/strip specifications). You can review the official ASTM catalog and standard information at astm.org, which is helpful for confirming scope, terminology, and revision history before locking a purchase spec.

Conductivity targets and “good copper” reality

If your design is sensitive to voltage drop or heat rise, conductivity is non-negotiable. A practical reference point is the IACS conductivity convention used throughout electrical industries; background on conductivity measurement and related metrology topics can be found through authoritative institutions like NIST. In real production, it’s not only the base grade—forming strain, local thinning, and post-form heat treatment can also influence performance, so the manufacturing plan must reflect the electrical requirements.

Deep Drawn Stamping Process Flow for High-Volume Copper Parts

Blank development and draw ratio planning

Successful deep drawn stamping begins with the blank. We model the part’s draw depth, corner radii, flange behavior, and thinning risk to select a safe draw ratio and determine whether redraw steps or ironing are required. For copper, conservative planning reduces the chance of splits at the punch radius and minimizes wrinkling at the flange.

Progressive die vs. transfer tooling decision

Not every copper geometry belongs in a progressive die, and not every cup demands a transfer press. A progressive deep drawn stamping approach can be ideal when features can be sequenced efficiently and strip control is stable. Transfer tooling can be the better option when the draw depth, part diameter, or feature access requires more open forming stations and better part handling during redraws.

Redraw, restrike, ironing, trim, and pierce—done in a controlled sequence

High-volume copper parts often need multiple forming stages: initial draw, redraw, flange forming, restrike for accuracy, trimming to final height, and piercing for assembly interfaces. The sequence matters because copper work-hardens, and each step changes the material’s behavior. When geometry and volume justify it, we also integrate in-die operations that reduce secondary processing and help keep the part “press-ready” for plating or assembly.

Tooling Engineering: The Real Secret to Repeatable Copper Deep Draws

Radii, clearances, and surface finish that protect copper

Copper is softer than many steels and will faithfully record tool marks. That means punch/die surface finish, draw radius design, and die clearances must be managed to prevent galling and cosmetic defects. In high-volume deep drawn stamping, tooling consistency is a quality strategy—not just a manufacturing detail—because tool wear shows up as scratches, dimensional drift, and burr changes.

Blank holder force, draw beads, and wrinkling control

Wrinkling and earing are common deep draw risks. With the correct blank holder force and bead strategy, we can stabilize material flow and reduce flange buckling. Copper’s anisotropy can also affect earing patterns, so we align coil direction, lubrication, and tooling geometry to keep the process stable across lots.

In-die sensing and automation for volume assurance

High-volume stamping lives and dies by uptime and fast detection of drift. In-die sensors, load monitoring, and camera inspection can catch misfeeds, slug issues, or draw anomalies early—before thousands of parts are affected. This kind of process control supports consistent output for demanding supply chains such as automotive and power electronics.

Quality Expectations: Tolerances, Surface, Burr, and Functional Performance

Dimensional control for assembly-ready copper components

A well-designed deep drawn stamping process can hold tight critical dimensions—diameters, heights, flange flatness, and pierce locations—when the forming sequence and restrike strategy are correct. We build control plans around CTQs (critical-to-quality characteristics) and use SPC where it provides real value. High volume is unforgiving, so stability is more important than chasing an unrealistic tolerance stack.

Burr strategy: minimize, orient, or eliminate

Burrs affect electrical contact, sealing, and safety in handling. We design trim and pierce operations with burr direction in mind and apply secondary deburring only when it’s truly necessary. When deburring is required, we select methods that preserve copper surface integrity and do not contaminate parts before plating or welding.

Compliance considerations for global markets

If your copper parts ship globally, regulatory compliance becomes part of quality. Many customers require RoHS conformity for electronics supply chains; official EU policy information is available at the European Commission RoHS page: environment.ec.europa.eu. Chemical compliance and candidate substance tracking may also tie into REACH requirements, which are detailed by ECHA at echa.europa.eu.

Finishing Options That Pair Well with Deep Drawn Copper Parts

Plating for contact performance and corrosion resistance

Copper parts frequently receive tin, nickel, or silver plating to improve contact behavior, corrosion resistance, or solderability. The deep drawn stamping plan should anticipate plating thickness, edge conditions, and rack/barrel constraints to prevent surprises late in validation. A great production shortcut is designing geometry and trim edges so that finishing is consistent and doesn’t require excessive post-processing.

Heat treatment and stress relief for stability

Because copper work-hardens, stress relief or annealing can be important for dimensional stability or downstream forming. The choice depends on your performance goals: sometimes you want strength and spring behavior, and other times you want ductility for crimping or joining. A controlled thermal plan reduces warpage risk and helps keep high-volume variation under control.

Design for Manufacturability Tips for High-Volume Deep Drawn Stamping

Use generous radii where it matters most

Sharp corners are the enemy of stable deep drawn stamping, especially with copper. Increasing punch and die radii in high-strain zones can dramatically improve yield and reduce cracking. Even small radius changes can pay back quickly when volumes are high and scrap costs are real.

Avoid “unnecessary depth” and over-constrained features

If a feature doesn’t add electrical or mechanical value, it may be adding risk. Very deep draws or extreme aspect ratios can force additional redraw stages, increase tool complexity, and slow production. A design review that focuses on function-first geometry can often reduce stations, stabilize quality, and shorten lead time.

Standardize holes, slots, and datums for better measurement and assembly

High-volume supply chains rely on fast measurement and predictable assembly interfaces. When datum strategy is clear and hole/slot families are standardized, quality control becomes simpler and your downstream partners see fewer surprises. In many cases, we can integrate locating features directly in the die set to improve repeatability.

Validation and Production Launch for High-Volume Programs

From prototype intent to production reality

Prototyping in deep drawn stamping should validate both geometry and manufacturability. Soft tooling or bridge tooling can confirm draw behavior and help lock key dimensions before investing in full-scale production tooling. This approach reduces late-stage rework and keeps the launch plan realistic.

Documentation, traceability, and automotive-style expectations

Many high-volume customers expect structured validation, traceability, and disciplined change control. If your supply chain uses PPAP-style thinking, your manufacturing partner should be ready to support it with clear process documentation and measurement evidence. For broader quality system context, ISO 9001 principles and requirements are described by ISO at iso.org, which can help align internal expectations between buyer and supplier.

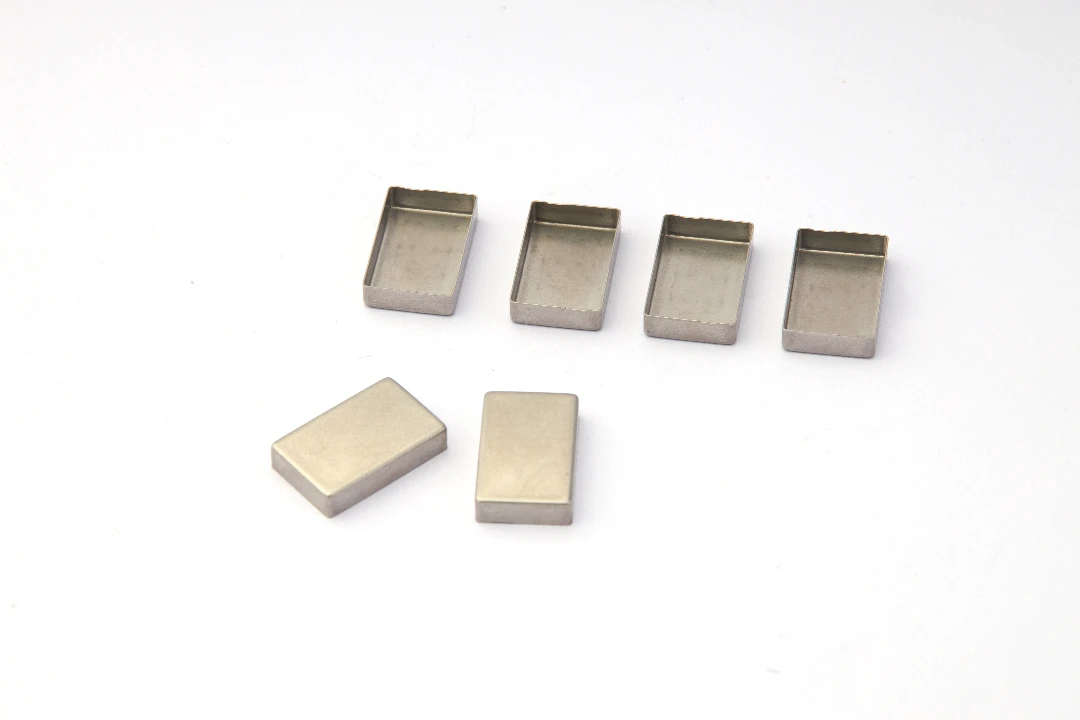

Typical High-Volume Copper Parts Made with Deep Drawn Stamping

Power and electrification components

Deep drawn stamping is well suited for copper parts used in EV and energy storage systems—protective caps, terminals, formed busbar elements, battery interconnect shells, and shielding components. These programs often demand consistent geometry for automated assembly, plus reliable conductivity under thermal cycling. When designed correctly, deep drawn copper parts provide a strong balance of performance and manufacturability.

Electronics housings, shields, and formed shells

For electronics, deep drawn copper shells can support EMI control, grounding strategies, and compact packaging. Copper’s conductivity and formability make it attractive, but quality requirements are strict—surface finish, cleanliness, and dimensional repeatability all matter. A stable deep drawn stamping process helps meet those needs at scale without turning the part into a “hand-finished” product.

Industrial connectors and high-current contact hardware

Copper contact hardware benefits from precise geometry and predictable edge conditions. When mating surfaces and fastener interfaces are involved, the die must deliver repeatable pierce position and minimal distortion. This is where experienced deep draw die engineering becomes a competitive advantage.

Why JUMAI TECH for Deep Drawn Stamping in Copper

Engineering-led quoting and DFM support

High-volume success starts before the press ever runs. We review part function, tolerance intent, joining method, and finishing requirements to build a manufacturable plan around deep drawn stamping. That helps prevent “quote-now, fix-later” cycles that waste time and budget.

Integrated capability: components plus stamping dies

JUMAI TECH supports both production and tooling needs—custom copper parts, deep-drawn components, and precision stamping dies and accessories. This integration speeds up iterations, reduces communication gaps, and keeps responsibility clear. When your delivery target is aggressive, eliminating handoffs can be the difference between a smooth launch and a delayed one.

Process stability designed for volume

High-volume production is not just “more parts.” It requires stable lubrication control, tool maintenance discipline, in-process detection, and repeatable measurement practices. Our deep drawn stamping approach is built around consistency—so your copper components arrive ready for assembly, plating, or joining with minimal variability lot to lot.

Request a Quote for Your High-Volume Copper Deep Drawn Stamping Project

If you’re evaluating deep drawn stamping for copper components—whether you need millions of parts per year or you’re preparing to scale—we can help you validate feasibility and optimize cost. Share your drawing, annual volume forecast, material preference, and critical requirements (conductivity, plating, sealing, burr limits, or cosmetic standards). We’ll respond with a practical manufacturing plan that focuses on stable production, predictable quality, and a clear path to high-volume success.

FAQ

What is deep drawn stamping?

Deep drawn stamping is a manufacturing process used to shape flat sheets of copper into three-dimensional parts. It involves stretching and forming the copper without cutting it, allowing for stronger and more efficient designs. This method is ideal for making parts like caps, housings, and terminals used in electronics and power systems.

Why is copper used in deep drawn stamping?

Copper is chosen for deep drawn stamping because it is an excellent conductor of electricity. This makes it perfect for parts that require high electrical performance. However, copper can be challenging to work with due to its softness and tendency to harden during shaping. Proper techniques and designs are used to ensure high-quality parts.

What are the benefits of deep drawn stamping for high-volume production?

Deep drawn stamping is efficient for producing large quantities of parts. It reduces waste material compared to other methods and makes assembling parts easier since they are often made as one piece. This process also ensures consistent quality, which is crucial for parts used in electric vehicles and electronic devices.

How does tooling impact the quality of deep drawn copper parts?

Tooling refers to the tools and dies used in the stamping process. Good tooling design can prevent defects like burrs and scratches on the copper parts. It ensures precise shaping and consistent quality in every piece produced. Attention to tooling is essential to avoid issues during mass production.

What should I consider when choosing copper materials for stamping?

When selecting copper materials for deep drawn stamping, consider factors like electrical conductivity and surface quality. Common grades such as C11000 are often used because they balance performance and cost. The chosen material will impact the part’s overall functionality and longevity in use.

What types of parts can be made with deep drawn stamping?

Deep drawn stamping can create a wide range of copper parts. Typical examples include electrical connectors, battery cases, protective covers, and components for electric vehicles. The ability to produce complex shapes makes it an ideal solution for many industries that require reliable and sturdy parts.

What is the importance of quality control in deep drawn stamping?

Quality control is vital in deep drawn stamping because small defects can affect the performance of the final part. It involves checking dimensions, surface finish, and ensuring that parts meet predefined standards. Effective quality measures help maintain consistency and prevent costly mistakes in production.

How can I ensure the best design for deep drawn stamping?

To ensure the best design for deep drawn stamping, focus on simplicity and function. Avoid sharp corners and overly complex geometries, as they can lead to issues in production. It’s also beneficial to standardize hole and slot sizes. Collaborating with an experienced manufacturer can help optimize your design for manufacturability.

Why choose JUMAI TECH for my deep drawn stamping projects?

Selecting JUMAI TECH means working with experts in deep drawn stamping who prioritize efficiency and quality. We specialize in both production and tooling, which helps streamline your project from design to manufacturing. Our commitment to process stability ensures that your copper parts arrive with consistent quality and performance.

How can I request a quote for a stamping project?

To request a quote for your deep drawn stamping project, you can visit our website and submit your details. Include your designs, yearly volume estimates, and any specific requirements like material choices or quality standards. We will review your project and provide you with a tailored manufacturing plan.