When your project needs millions of identical, tight-tolerance parts—delivered on schedule, at a predictable cost—few processes compete with progressive die stamping. It combines speed, repeatability, and automation in a way that fits modern supply chains, especially for electrical, automotive, industrial, and electronics applications where consistency is non-negotiable. At JUMAI TECH, we build production around robust tooling, disciplined process control, and practical design-for-manufacturability, so your precision parts stay stable from first articles to the last box in the last run.

What Progressive Die Stamping Is and Why It Works

Progressive die stamping, explained simply

Progressive die stamping is a metal forming process where a coil strip feeds through a multi-station die set. At each station, the strip is progressively shaped—pierced, notched, embossed, formed, coined, or cut—until the finished part is separated at the final station. Because the strip advances with every press stroke, the process is naturally suited for high volume with very consistent cycle time.

In practical terms, it means you get one part per stroke (after the die is up to speed), with minimal handling and excellent repeatability. The die itself becomes the “factory inside the press,” combining multiple operations into one controlled, synchronized sequence.

How it differs from single-hit stamping and transfer stamping

Single-hit stamping uses one operation per press cycle, often requiring multiple dies or multiple machines to complete a part. That approach can work for lower volume or simple features, but it increases handling, WIP, and opportunities for variation. Transfer stamping can be great for larger formed parts, but it typically involves more part movement and more complex automation.

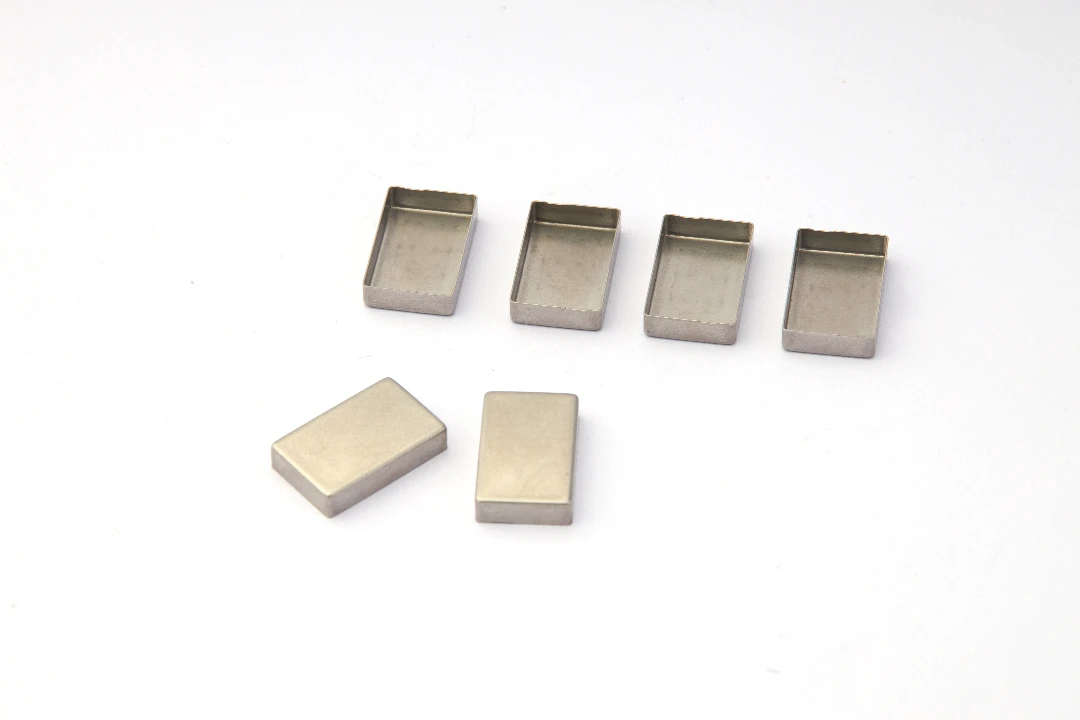

Progressive die stamping shines when your part geometry can be built from a strip layout and you want high output, stable quality, and lower piece price at scale. For many precision connectors, clips, terminals, shields, brackets, and copper current-carrying components, it becomes the most reliable path to mass production.

Why Progressive Die Stamping Is the Go-To for High-Volume Precision

Output and cost stability at scale

High-volume manufacturing is not just about speed—it’s about predictable cost per part and predictable quality. With progressive die stamping, cycle time is consistent, scrap can be engineered down through smart strip layout, and labor content is typically lower because the process is highly automated. Once the tooling is tuned, the process runs like a metronome, which is exactly what OEM and Tier suppliers want.

Tooling investment is real, but it buys you long-term stability. Over millions of strokes, progressive dies distribute cost efficiently, often beating multi-step methods on total cost of ownership.

Repeatability and process control

Progressive dies are designed with built-in alignment and repeatability, using features like pilots, lifters, guides, and precision ground components. Combined with consistent coil feed and press control, this enables tight dimensional repeatability across long runs. That repeatability becomes even more valuable when your downstream assembly is automated and sensitive to variation.

If your supply chain requires traceability and documented quality systems, progressive die stamping integrates well with production control methods aligned with recognized quality frameworks such as ISO 9001 (overview on ISO’s site: https://www.iso.org/iso-9001-quality-management.html).

Typical Parts Made with Progressive Die Stamping

Electrical and electronics components

Progressive die stamping is widely used for electrical and electronics because it handles thin gauges, precise features, and consistent geometry at speed. Common examples include terminals, contact springs, lead frames, EMI shielding parts, sensor housings, and structural brackets. When copper or copper alloys are involved, progressive stamping is often paired with deburring, plating, or selective finishing to support conductivity and corrosion resistance.

If you’re building precision copper busbars or related current-path components, progressive stamping can create consistent profiles, holes, slots, and formed features that support fast assembly and reliable electrical contact.

Automotive and industrial precision parts

Automotive programs demand scale, consistency, and documentation, which aligns with progressive die stamping. Clips, retainers, brackets, heat shields, and connector components are frequently made this way, especially where multi-feature geometry must remain consistent across long production schedules.

Many automotive supply chains reference structured quality requirements such as IATF 16949 (official information: https://www.iatfglobaloversight.org/). Even when a part is not automotive, those disciplined practices often improve consistency and supplier performance.

Medical, aerospace, and other high-reliability applications

For regulated or high-reliability products, process control and documentation matter as much as geometry. Aerospace supply chains often reference AS9100 (IAQG overview: https://iaqg.org/as9100-series/), and progressive die stamping can support those requirements through controlled inspection plans, traceability, and validated tooling.

Not every part is suitable for progressive stamping, but when it is, the process offers a powerful combination of precision and throughput.

The Progressive Die: Stations, Strip Layout, and “Hidden Engineering”

How strip layout drives cost and quality

The strip layout is the blueprint of your progressive process. It defines part orientation, station sequence, carrier design, web thickness, and scrap rate. A good layout reduces scrap, improves stability, and prevents distortion by balancing forces across stations. A poor layout can cause feed issues, part twist, burr direction problems, or premature tool wear.

Cost is often decided here. A few percentage points of material utilization can be the difference between a program that runs comfortably and a program that constantly fights margin pressure.

Station sequencing: building features without distortion

Smart station sequencing is about managing metal flow and preventing cumulative error. Typically, piercing and pilot features appear early to control strip position. Forming operations follow in a planned progression, and final cutoff is designed to avoid tearing or burr problems.

If your part includes formed tabs, bends, embosses, or coined surfaces, sequencing is critical. The die must create those features without over-stressing the strip or shifting critical datums.

Tool steels, coatings, and wear management

Progressive die stamping for high volume is a wear game. Punches, dies, and forming inserts must be selected for the material, thickness, and production rate. Tool steels, heat treatment, and surface coatings are chosen to resist galling, chipping, and abrasive wear.

Stable wear behavior improves dimensional consistency, reduces unplanned downtime, and keeps your “good parts per hour” steady across the entire program.

Materials: Choosing the Right Metal for Precision and Performance

Copper, copper alloys, and conductivity-driven design

Copper and copper alloys are common in busbars, connectors, and thermal or electrical components. Each alloy balances conductivity, strength, spring properties, and formability. If conductivity is a key driver, selecting the right grade—and then designing the stamping process to preserve flatness and contact quality—can significantly impact performance.

For general copper information, properties, and application guidance, industry resources like the Copper Development Association are useful references: https://copperalliance.org/.

Stainless steel, carbon steel, and plated materials

Stainless steels are popular for corrosion resistance and strength, while carbon steels can deliver cost-effective strength when properly protected by coating or plating. Many stamped parts use plated coil stock or post-stamp plating to meet corrosion and solderability requirements.

Material choice affects not just part performance, but also tooling wear, burr behavior, and achievable tolerances. That is why material selection should be handled together with DFM and die design.

Thickness, temper, and coil quality

Even with the best die design, inconsistent coil thickness or temper can cause variation. High-volume progressive stamping depends on stable inputs: consistent thickness, flatness, and surface quality. When a program is sensitive to variation, we recommend aligning on incoming inspection criteria and working with qualified mills and service centers.

Design for Manufacturability in Progressive Die Stamping

Tolerances: where to be strict and where to be practical

Not every feature needs microns of control, but the features that locate, mate, or carry current often do. The most effective approach is to identify critical-to-function dimensions and control them tightly, while keeping non-critical dimensions realistic for the process and material. This strategy improves yield and reduces cost without compromising performance.

If your project requires statistical control, modern quality systems commonly rely on methods like SPC and measurement system analysis. NIST provides foundational measurement and calibration resources that many industries reference: https://www.nist.gov/.

Burr direction and edge quality

Burrs are a reality in stamping, but burr direction and size can be engineered. Progressive die design, punch/die clearance, and station sequencing influence burr formation. For parts that must be assembled automatically or make electrical contact, burr control and deburring strategy should be decided early.

Edge quality can also influence plating performance, corrosion behavior, and mating reliability. Planning for post-stamp finishing is often part of a cost-effective solution, not an afterthought.

Part symmetry, forming limits, and “strip-friendly” geometry

Progressive dies prefer strip-friendly parts: features that can be built progressively without extreme deformation or unstable carriers. Tight inside radii, deep forms, or highly asymmetrical shapes can still be possible, but they usually require more stations and more die complexity.

If the part is better suited for deep drawing or hybrid forming, we will recommend that. At JUMAI TECH, we support both deep-drawn components and stamping solutions, which allows us to choose the most stable manufacturing path instead of forcing one process.

Process Flow: From Coil to Finished Precision Parts

Coil handling, feeding, and press control

A stable progressive stamping line starts with coil handling. Decoilers, straighteners, and feeders must be sized and tuned for the material and thickness. Consistent feed length, minimal camber, and reliable pilot engagement keep the strip positioned correctly at every station.

Press selection matters too. Stroke rate, tonnage, shut height stability, and dynamic behavior all affect quality at scale. When high speed is required, the entire system—press, feed, die—must be engineered as one.

In-die operations and part ejection

Within the die, parts may be formed, coined, shaved, or embossed. Some programs add in-die tapping, in-die sensing, or in-die part separation strategies to improve throughput. Part ejection and collection must protect the part from damage and keep counts accurate.

For safety and compliance, machine guarding and safe operation are essential. OSHA provides clear baseline guidance on machine guarding principles and requirements: https://www.osha.gov/machine-guarding.

Secondary operations: when they add value

Not all parts are “done” when they exit the die. Secondary operations may include deburring, cleaning, heat treatment, plating, passivation, or assembly. The best programs plan these steps early so that throughput and cost remain predictable.

For example, if a copper contact requires a specific plating to improve corrosion resistance or solderability, the stamping design should accommodate the plating process and any racking or reel-to-reel constraints.

Quality Assurance: How We Keep High-Speed Production Precise

First article, capability, and ongoing inspection

A high-volume program typically begins with first article inspection and continues into capability studies once the line is stable. We build inspection plans that match your drawing requirements and your functional risks, including dimensional checks, visual checks, and performance-related verification where needed.

Inspection frequency should be set based on risk and stability, not guesswork. The goal is to catch variation early without slowing production unnecessarily.

Metrology that matches your tolerances

Precision parts require appropriate metrology. Depending on the geometry, this may include optical comparators, CMM, vision systems, and custom gauges. Stable measurement is critical, because you cannot control what you cannot measure reliably.

If the application is safety-critical or regulated, we can support additional documentation such as control plans, gauge R&R summaries, and traceability records.

In-process monitoring and mistake-proofing

Progressive die stamping can incorporate sensors to detect misfeeds, strip end, slug pull, or part ejection issues. These controls protect the tooling and reduce the risk of mixed lots. The result is fewer interruptions, fewer quality incidents, and better on-time delivery performance.

Cost Drivers in Progressive Die Stamping

Tooling complexity vs. piece price

Progressive dies can be simple or highly complex. More stations often mean more capability and more stable forming, but also higher tooling cost. The right balance depends on volume, tolerance, material, and feature complexity.

A strong supplier will explain the trade-offs clearly. We typically recommend a tooling approach that protects long-term stability, because the cheapest die on day one often becomes the most expensive die over the life of the program.

Material utilization and scrap rate

For many stamped parts, material is the largest recurring cost. Improving strip utilization is one of the fastest ways to reduce piece price. That is why layout optimization—part orientation, nesting, carrier design, and web control—is a core part of our quoting and engineering process.

Tool maintenance and uptime

High-volume stamping is a marathon. Preventive maintenance, spare inserts, and defined sharpening intervals keep output stable and reduce unplanned stops. We design tooling for maintainability so that wear items can be serviced efficiently without compromising alignment and part quality.

Progressive Die Stamping + JUMAI TECH Capabilities

A single partner for stamping, deep drawing, and copper-focused components

Many customers need more than one forming method across a product family. Some parts are ideal for progressive die stamping, while others require deep drawing for seamless shapes or leak-tight enclosures. By supporting both, we help customers reduce supplier complexity and align manufacturing strategy across the entire program.

If your project includes Precision Copper Busbars, stamped connectors, or deep-drawn housings in the same assembly, having a unified engineering approach improves compatibility and reduces iteration.

Engineering support from DFM to production launch

We support customers from early DFM through tool build, sampling, validation, and mass production. Clear communication, documented revisions, and practical feedback help avoid late-stage surprises that delay schedules.

When required, we also support quality documentation aligned with your supplier requirements and industry expectations. Whether your reference point is ISO-based systems or automotive-style discipline, the goal remains the same: consistent parts, delivered on time.

A Practical DFM Checklist for Your RFQ

What to include to speed up quoting and improve accuracy

To quote progressive die stamping accurately, we recommend sharing your 2D drawing, 3D model when available, material specification, thickness, temper, and target volume. It also helps to clarify critical features, functional surfaces, and any downstream requirements such as plating, heat treatment, or assembly constraints.

If you already have packaging requirements, labeling formats, or traceability expectations, share them early. Those “details” often influence process flow and total cost more than buyers expect.

Common issues that delay programs

Unclear tolerances, missing material callouts, and late changes to critical features are common sources of delay. Another frequent issue is underestimating the effect of burr direction, flatness requirements, or contact surface condition in electrical parts.

We reduce these risks by addressing them upfront in DFM discussions and aligning expectations before tooling is cut.

Frequently Asked Questions About Progressive Die Stamping

What volumes justify progressive die stamping?

There is no single number, but progressive die stamping is usually most attractive when volume is high enough to amortize tooling over the life of the program. For some simple parts, that threshold can be lower; for complex parts, higher. What matters is the relationship between tooling cost, material utilization, cycle time, and your required quality level.

If your forecast includes long-term repeat orders, progressive stamping often provides the best stability and piece price.

How tight can tolerances be?

Achievable tolerances depend on material, thickness, geometry, station design, and press stability. Many precision stamped parts hold tight tolerances reliably, but the best approach is to identify critical dimensions and engineer the die and inspection plan around them.

When tolerances are extremely tight, secondary sizing, coining, or controlled forming strategies may be used to improve repeatability.

Can progressive stamping handle copper busbar features?

Yes, many busbar-related features—holes, slots, tabs, profiles, and formed bends—are well suited to progressive die stamping. The key is selecting the right alloy/temper and engineering the process to protect flatness and contact integrity.

For thicker or more complex current-path parts, we may recommend a hybrid approach, depending on performance requirements.

Build High-Volume Precision with a Process Designed to Repeat

If your product needs high-volume precision parts with consistent quality and predictable cost, progressive die stamping is one of the most proven manufacturing methods available. When it’s engineered correctly—strip layout, station sequencing, tooling materials, press selection, and quality control—it delivers the combination every buyer wants: throughput, stability, and confidence.

If you’re sourcing progressive die stamped components, precision copper busbars, or deep-drawn parts, JUMAI TECH can support you from DFM through mass production. Share your drawing and target volume, and we’ll help you choose the most stable, cost-effective path to production.

FAQ

What is progressive die stamping?

Progressive die stamping is a metal forming process where a long strip of metal is fed through a series of stations in a die. At each station, the metal is shaped a little more until it becomes the final part. This method allows for the speedy production of many identical parts with high precision.

What types of parts can be made with progressive die stamping?

This method is great for making parts used in electronics, automotive, and medical devices. Common examples include connectors, clips, brackets, and other components that need to be made in large quantities while maintaining high quality.

Why is progressive die stamping preferred for high-volume production?

Progressive die stamping is preferred for high-volume production because it combines speed, automation, and consistent quality. It allows manufacturers to produce millions of parts quickly and economically, making it ideal for industries that require reliable and repeatable outputs.

How does progressive die stamping save money?

It can save money by reducing scrap material and minimizing labor costs thanks to its automated processes. The tooling used can also produce parts relatively quickly, allowing for lower costs per piece, especially when producing large quantities.

What are typical tolerances in progressive die stamping?

Tolerances in progressive die stamping can be very tight, depending on the part’s design and material. Most parts can achieve high precision, but the best method is to identify which dimensions are essential for the part’s function and focus on controlling those tightly.

Can progressive die stamping work with copper?

Yes, progressive die stamping can effectively handle copper and its alloys. It is excellent for creating parts like busbars and electrical connectors, ensuring that these critical components maintain their shape and conductive properties.

What is the role of tooling in progressive die stamping?

Tooling in progressive die stamping refers to the specialized dies that shape the metal into the desired parts. Properly designed tooling is crucial for producing parts consistently and efficiently. Quality tooling can reduce downtime and improve overall production stability.

How is quality assurance maintained during production?

Quality assurance is maintained through various methods such as regular inspections, precise measurement techniques, and monitoring systems. These ensure that any variations in parts are detected early, which helps maintain high standards and prevent defects.

What should I provide for a quote on progressive die stamping?

To get an accurate quote, you should provide a 2D drawing or 3D model of the part, material specifications, thickness, and target volume. Sharing details about critical features and any specific requirements can also help expedite the quoting process.

What issues can delay the progressive die stamping process?

Common issues that can cause delays include unclear tolerances, missing material specifications, or last-minute changes to part design. Addressing these concerns early in the design phase can help keep the project on schedule.