A stamping die is the “engine” behind consistent, high-volume sheet metal parts—whether you’re making precision copper busbars, deep-drawn housings, terminals, shields, brackets, or complex progressive components. When the die is designed with the end in mind (material behavior, press realities, inspection strategy, and maintainability), you get first-off samples that match prints—and a production tool that stays stable for the long run. This guide explains the stamping die journey from idea to first-off samples in a practical, easy-to-follow way, based on real tooling and tryout workflows.

Table of Contents

What Is a Stamping Die and Why It Matters

A simple definition (without the jargon)

A stamping die is a precision tool installed in a press to cut and/or form metal into a repeatable shape. It controls the part’s geometry through guided motion, controlled clearances, and carefully designed forming surfaces.

Unlike “general fixtures,” a stamping die must survive thousands—or millions—of hits while holding tolerances, so its design always balances accuracy, wear life, and press efficiency.

Where stamping dies show up in real products

Stamping dies are used across automotive, electronics, energy, and industrial supply chains because stamping scales well and produces stable parts. Copper busbars, for example, are often blanked and pierced with controlled burr direction, then formed to fit assemblies with minimal resistance and heat rise.

If you’re working with copper, understanding conductivity and alloy selection is also part of tool planning, and the Copper Development Association has a solid overview of copper’s electrical/physical properties (including conductivity context) on copper.org.

Why “first-off samples” are a die milestone

First-off samples are the first verified parts produced from the die under controlled conditions. They demonstrate that the die can meet print requirements and that inspection methods are aligned to the drawing.

A good first-off is not “luck”—it is the result of good die concept choices, correct assumptions, disciplined tryout, and measurable acceptance criteria.

Inputs That Shape the Die Concept

Start with function, not only geometry

A stamping die concept begins with what the part must do in the product. Electrical contact areas, sealing zones, weld features, and assembly datums should be identified early because they drive where you can place pilots, carriers, and trim lines.

When the functional zones are clear, the die designer can protect critical surfaces, choose safer forming directions, and reduce risk during tryout.

Material selection changes everything

The same geometry behaves differently in different materials, and that directly impacts die clearance, radii, springback control, and tonnage. Copper and copper alloys, for example, can be highly conductive and formable, but they also require burr control, surface protection, and careful handling to avoid dents or scratches.

If your drawing calls out specific copper strip or plate requirements, standards such as ASTM B152 are commonly referenced in purchasing and quality language, and you can find the standard’s scope/details on ASTM’s site here: ASTM B152/B152M.

Tolerances, datums, and inspection strategy

A die does not “make tolerances” by itself—tolerances come from how the strip is piloted, how the die is guided, where the part is supported during forming, and how trim is controlled. Those decisions must be made together with an inspection approach (CMM strategy, go/no-go gauges, optical measurement, or specialized checks).

If the print is tight, the fastest path is usually to define which features are “tooling-controlled” vs. “process-controlled,” then build the concept around protecting the tooling-controlled datums.

DFM That Prevents Pain in Tryout

Strip layout and process direction

Strip layout is the backbone of most stamping die designs, especially in progressive tooling. It determines material utilization, station count, carrier strength, and whether critical cuts happen before or after forming.

A strong layout also considers grain direction, burr direction requirements, and how the part will exit the die without distortion.

Tonnage, energy, and press reality

Press tonnage isn’t only about “can it cut.” You must consider forming loads, dynamic effects, shut height window, bed size, and how rigid the press is under load. A die concept that ignores press behavior often creates first-off problems like inconsistent burr, out-of-flat conditions, or station-to-station shift.

If you’re aligning tooling to customer production lines, basic press selection concepts are widely discussed in manufacturing references such as The Fabricator (for practical shop-floor guidance), for example here: The Fabricator – Stamping fundamentals.

Simulation and forming limits (when it’s worth it)

For deeper forms, thin-wall housings, or complex draw features, simulation can reduce iterations by predicting thinning, wrinkling risk, and strain concentration. Even when simulation is not used, experienced designers still apply “forming limit thinking” in radii selection, draw bead intent, and restrike planning.

For deep-drawn parts, it’s often cheaper to validate early with a draw-focused concept than to “force it” into a cutting-first approach that later cracks or wrinkles in production.

Choosing the Right Die Type

Single-station dies (blanking, piercing, forming)

A single-station stamping die is ideal when volumes are moderate, part geometry is simple, or multiple operations are not cost-effective to combine. It can also be the right choice for early-stage programs where engineering changes are still likely.

Single-station tooling is often faster to modify, and it can produce clean first-off samples when the design protects key datums and controls part release.

Compound dies for precision cutting

Compound dies perform multiple cutting actions in one stroke, which can improve positional accuracy between related cut features. They are commonly used when concentricity or relative position is critical and forming is limited.

However, compound tooling can be less flexible than progressive solutions when you later add features, and it can increase press demands due to the combined cutting load.

Progressive dies for high-volume consistency

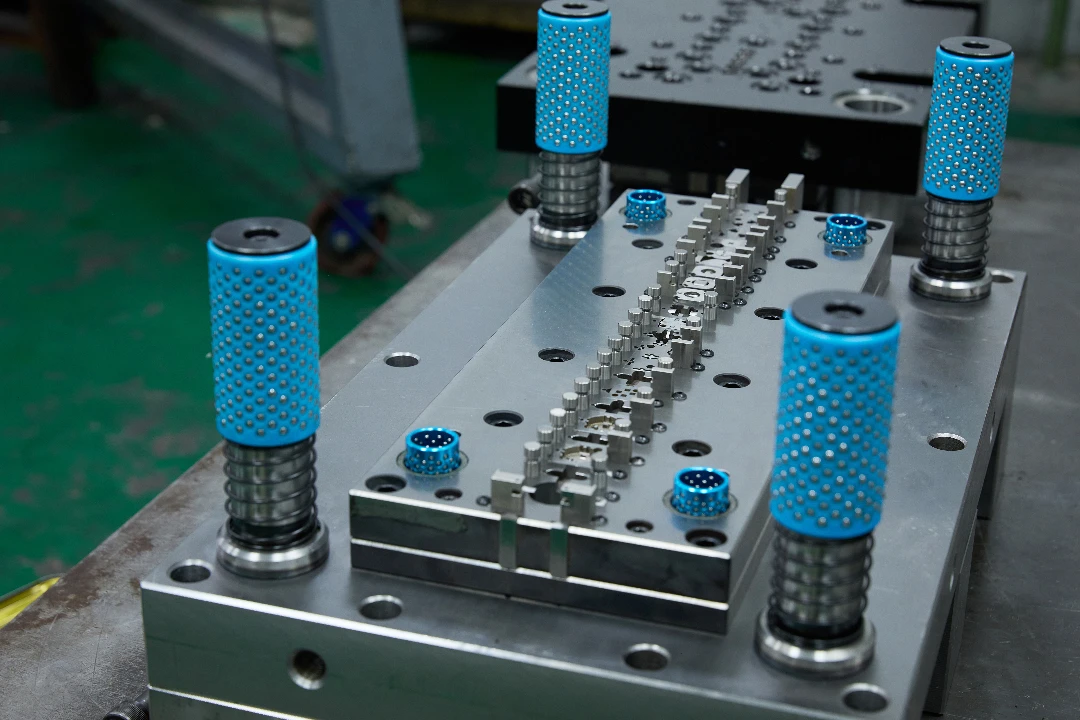

Progressive stamping dies move the strip through stations, with each hit completing a set of operations until a finished part is produced. They are often the best route for high-volume precision parts because they reduce handling and stabilize feature-to-feature relationships through piloting.

A good progressive die concept also anticipates maintenance by using replaceable wear components and by designing stations that can be accessed and serviced without excessive downtime.

Transfer tooling and deep-draw dies

Transfer dies move a part between stations (often with mechanical fingers or automation) and are common for larger parts or complex forming sequences. Deep-draw tooling specifically manages material flow into a cavity, typically using draw rings, blank holders, and sometimes beads to control wrinkling and thinning.

If your part resembles a cup, shell, or leak-sensitive housing, deep draw experience matters because controlling material flow is the difference between stable first-off samples and endless tryout loops.

Anatomy of a Stamping Die

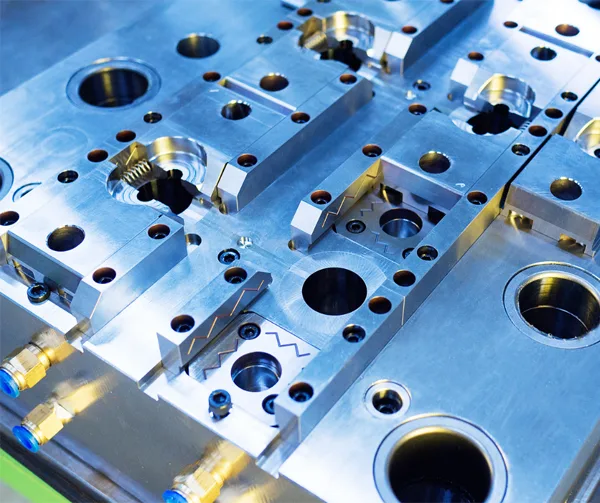

Die set, alignment, and guiding

The die set (upper and lower shoes) provides structure and alignment, while guide posts/bushings maintain repeatability stroke after stroke. If guiding is weak, everything else suffers—clearances drift, punch-to-die alignment changes, and wear accelerates.

Stable guiding reduces burr variation and helps maintain part geometry, especially when dealing with tight copper busbar positional tolerances.

Punches, inserts, and wear parts

Punches do the cutting and forming work, and they take the highest local stress. In most production dies, critical edges are built as inserts so they can be replaced or reground without rebuilding the entire tool.

Designing a die for maintainability is not “nice to have”—it directly affects cost per part and long-term stability.

Tool steels, heat treatment, and coatings

Tool steel choice depends on what is happening at the edge: abrasive wear, chipping risk, galling, or impact fatigue. Heat treatment and surface finish are just as important as the steel grade, and coatings may help in specific conditions such as high-volume stainless or adhesive materials.

If you want a general overview of tool steels and metallurgical considerations, ASM International provides educational material and references here: ASM International.

Springs, nitrogen, and control of stripping/pressure

Many dies rely on springs or nitrogen cylinders to control stripping force, blank holding, and return motion. Consistent force is essential for stable part release and for controlling deformation during forming.

When pressure systems are under-designed, first-off samples may look acceptable but production will show variability as components heat up, wear, or drift.

How a Stamping Die Is Built

Machining routes: CNC, EDM, grinding, and fitting

A typical build uses CNC machining for pockets and forms, wire EDM for precise cut profiles, sinker EDM for sharp internal forms, and grinding for critical flatness and parallelism. Hand fitting (spotting) still matters because a die is a precision mechanical system, not just a set of CAD surfaces.

The goal is not only to “match CAD,” but to achieve correct contact patterns, stable guidance, and predictable part release.

Tolerance control inside the tool (not just on the part)

Die makers control internal tolerances such as punch-to-die clearance, guide alignment, shut height stack-up, and station timing. These internal controls determine whether the die repeats or slowly drifts.

When customers ask why a stamping die costs what it costs, this hidden precision work is usually the answer.

Tryout Workflow: From First Hit to First-Off Samples

Spotting and contact pattern control

Spotting uses transfer media (like spotting blue) to verify where surfaces contact and where gaps exist. The die is adjusted so load is supported where intended, preventing local overload that causes chipping or dimensional instability.

This step looks old-school, but it is one of the fastest ways to move from “it hits” to “it repeats.”

Cutting clearance, burr control, and edge quality

Clearance influences burr height, edge rollover, and tool life. For copper busbar and electrical parts, edge condition can affect assembly, contact resistance, plating quality, and even safety if sharp edges remain.

Edge quality is also a measurable acceptance item, and many teams align on burr direction and allowable burr limits during first-off approval.

Forming stability and springback tuning

Forming rarely behaves perfectly on the first run, especially with bend-dominant parts. Tryout may include adjusting radii, adding restrike operations, modifying draw surfaces, or tuning blank holding to stabilize shape.

A disciplined approach focuses on controlling the key datums first, then tuning secondary features once the foundation is stable.

First-off inspection and feedback loop

First-off samples should be checked against the drawing using agreed measurement methods. The most efficient workflow links inspection results directly to die adjustments, so the die team can correct root causes rather than “chasing numbers.”

If you operate under a quality system, aligning inspection and corrective actions to recognized frameworks like ISO 9001 helps keep approvals clear and auditable.

What “Good” First-Off Samples Actually Mean

Dimensional compliance with a process window

A single perfect part is not enough; a good first-off result shows repeatability across a small run, under controlled press settings. That means you verify not only dimensions, but also the stability of the process window (feed accuracy, lubrication condition, and press parameters).

This is especially important for progressive dies, where tiny station shifts can compound into larger errors at the final station.

Surface, flatness, and functional checks

For busbars and electrical parts, surface condition and flatness can matter as much as hole position. Deep-drawn housings may require checks related to leak paths, flange flatness, or sealing interfaces depending on the application.

First-off acceptance should reflect functional reality, not only “what is easy to measure.”

Documentation customers often expect

Depending on the industry, customers may request first article documentation, capability planning, control plans, or PPAP-style packages. Even when not formally required, providing clear measurement reports and process notes accelerates approvals.

If your customers use automotive-style workflows, AIAG provides general information about PPAP and core tools here: AIAG.

Keeping the Die Healthy After Approval

Preventive maintenance is part of die design

A stamping die should be designed so wear parts can be serviced quickly, with clear access and consistent reassembly. The best production outcomes come from a die that is easy to maintain, not from a die that is “clever but fragile.”

Good maintenance planning protects quality and uptime, especially when volumes ramp.

Spare parts and predictable tool life

Punches, inserts, springs, and guides are common spare items, and planning spares early prevents costly downtime later. When spares are standardized and documented, your factory can keep the die stable without re-qualifying the whole tool.

For high-volume copper work, spare strategy is often the difference between stable delivery and unexpected line stops.

Why JUMAI TECH for Stamping Dies and First-Off Samples

One team for stamping dies, deep draw, and copper precision work

JUMAI TECH supports global customers with precision stamping dies, die components/spare parts, and production for precision copper busbars and deep-drawn components. That combination matters because the best stamping die decisions come from understanding downstream production realities—material handling, burr and surface risks, forming stability, and inspection practicality.

When your tooling team and production team speak the same language, first-off samples come faster and approvals become smoother.

Faster iteration without losing control

Speed is important, but uncontrolled speed creates rework. Our approach focuses on clear concept selection, disciplined DFM, measurable tryout steps, and a structured first-off inspection loop so changes are made for root-cause reasons.

That keeps the project moving while protecting the long-term stability of the stamping die.

Ready to start? What to send for a quick die review

If you want a fast, practical review, prepare your 2D drawing (PDF/DWG), 3D model (STEP/IGES), material spec, expected annual volume, and any special requirements such as burr direction, surface protection, plating, or assembly datums. Include your target press details if known, because press constraints shape the stamping die concept from day one.

With those basics, we can recommend an efficient die type, outline the tryout plan, and align on what “first-off samples” should prove—before anyone cuts steel.

FAQ

What is a stamping die?

A stamping die is a special tool that helps shape and cut metal into specific designs in a machine called a press. Think of it like a cookie cutter for metal! It ensures that the pieces are made accurately over and over again, making it really important for producing high-quality metal parts.

Why are “first-off samples” important?

“First-off samples” are the first pieces made by the stamping die. They are important because they show if the die can create parts that meet exact specifications. It’s like a test run to make sure everything works as it should before producing many parts.

What does the term “tolerance” mean in stamping?

Tolerance refers to how much difference is allowed in measurements of the metal parts made by the die. Just like how sometimes your shoelaces might not be tied exactly the same way but still work fine, tolerances ensure parts can still function well even if they’re not perfect.

How do you choose the right type of stamping die?

Choosing the right die depends on how many parts you need and how complicated they are. For simple shapes, a single-station die works well, while complex shapes or high volumes might need progressive dies that operate through several steps. It’s about matching the tool to the job!

What materials are used for stamping dies?

Stamping dies are made from strong materials called tool steels. These materials need to handle a lot of stress since the die is hit many times. Choosing the right type of steel helps the die last longer and work better.

What happens during a tryout workflow?

A tryout workflow is like a practice run for the stamping die. The die is tested to see how well it creates the parts. Any bumps in the process are fixed, and adjustments are made to ensure everything works perfectly before starting full production.

How do you maintain a stamping die after it’s approved?

After a stamping die is approved, it’s vital to keep it in good shape! Regular maintenance, like checking and replacing worn-out parts, helps make sure the die continues to work effectively and makes quality parts over time.

Can I see sample parts before ordering a die?

Yes! Before ordering, you can usually request to see sample parts. This gives you an idea of what types of parts the die can produce, ensuring it meets your needs.

How can I prepare for a quick die review?

To prepare for a quick review of your die needs, gather your 2D drawings, 3D models, and any special requirements you have, like material type or production volume. This information helps the team understand your requirements better and suggest the right solution.

Why choose JUMAI TECH for stamping dies?

JUMAI TECH is a great choice because we combine our knowledge of stamping dies with actual production experience. This means we understand both how to design the die and how to make high-quality parts, which helps speed up the process!