When customers choose a deep-drawn metal component or a precision copper busbar, they are not just buying a part—they are buying confidence. At JUMAI TECH, we like to describe that confidence as every deep drawn breath: a steady, repeatable rhythm of engineering discipline, controlled forming, and measurable quality at every step. That mindset matters whether you are building EV power distribution, EMI-shielded electronics housings, medical hardware, or rugged industrial assemblies.

This article explains what “every deep drawn breath” means in real manufacturing terms, and how it translates into dependable deep-drawn components, precision stamping dies, and custom copper busbars for global OEM projects.

Table of Contents

What “Every Deep Drawn Breath” Really Means in Manufacturing

Breath as a Process, Not a Slogan

In metal forming, quality is never a single event. It is the outcome of hundreds of small decisions—material selection, blank prep, lubrication, draw-bead strategy, punch radii, press stability, die alignment, inspection discipline, and packaging consistency. When we say every deep drawn breath, we mean quality is designed into the process so it can be repeated, verified, and scaled.

That repetition is the difference between a sample that “looks good” and a production part that keeps working after vibration, heat cycling, torque load, and long service life. In other words, “breath” is stability—each press stroke producing the same reliable result.

Why This Matters to OEM Buyers

OEM teams don’t just need parts; they need predictable outcomes. Stable forming reduces rework, scrap, line stoppages, and downstream assembly issues, especially when deep-drawn shells must fit with gaskets, weld rings, insulating films, or shielding features.

The best suppliers speak the language of risk control: tolerances, Cp/Cpk, inspection plans, traceability, and design verification. That is the heart of every deep drawn breath—turning complexity into controllable manufacturing.

Deep Drawing 101—From Flat Sheet to Precision Geometry

The Step-by-Step Reality of Deep Drawing

Deep drawing transforms a flat blank into a hollow or semi-hollow part by forcing material to flow into a die cavity under controlled restraint. If you want a clear overview of how blank sizing, draw steps, and redraw planning work, this “deep drawing step by step” explanation is a practical reference for engineers and buyers alike: Die Science: Deep drawing step by step (The Fabricator). The Fabricator

In real production, most “simple looking” drawn parts are the result of careful balancing between material flow and restraint. Too much restraint leads to tearing; too little creates wrinkling or unstable walls.

Common Failure Modes—and How We Prevent Them

Most deep drawing issues fall into a few categories: wrinkles, tears, thinning, earing, and dimensional springback. These are not random defects—they are symptoms of controllable variables such as lubrication, blankholder pressure, draw bead layout, punch/die radii, and material anisotropy.

A strong supplier doesn’t treat defects as “bad luck.” We treat them as engineering signals, then adjust the forming window until the process breathes steadily—stroke after stroke.

Designing Deep-Drawn Parts That Manufacture Cleanly

Geometry Rules That Keep Parts Stable

Deep drawing rewards “flow-friendly” geometry. Generous radii, consistent wall transitions, and realistic height-to-diameter expectations reduce risk and cost. When early geometry ignores forming physics, you end up paying for extra draw stages, tighter lubrication control, and more intensive inspection.

If you want a compact set of design principles—material effects, thickness considerations, and practical tips—this overview is helpful: Deep drawing: Key design principles & tips (The Fabricator). The Fabricator

DFM Collaboration: Where Cost and Quality Are Won

The cheapest part is rarely the one with the lowest quote; it’s the one that runs smoothly at scale. Early DFM reviews let us align tolerance targets to real forming capability, choose the right draw sequence, and avoid cosmetic requirements that create unnecessary scrap.

This is where every deep drawn breath becomes a measurable advantage: fewer tool revisions, fewer surprises during ramp-up, and a faster path from prototype to stable mass production.

Material Selection—Why the Right Alloy Is Half the Job

Copper and Copper Alloys for Conductivity-Driven Parts

For power distribution and high-current designs, copper is often selected for its conductivity and reliability. The Copper Development Association explains conductivity in terms of %IACS (International Annealed Copper Standard) and provides background engineers use for connectors and electrical applications: Copper.org—Electrical Conductivity (IACS). Copper Development Association

Material choice is never only about conductivity, though. Formability, grain direction, thickness, temper, and surface condition all influence deep draw performance and final dimensional stability.

Using Standards to Avoid Material Ambiguity

For copper sheet, strip, and plate, many buyers reference ASTM requirements to reduce ambiguity in ordering and inspection. One widely used standard is ASTM B152/B152M for copper sheet/strip/plate and rolled bar: ASTM B152/B152M standard page. ASTM International | ASTM

Standards don’t magically guarantee a perfect part, but they help align chemistry, temper expectations, and documentation across a global supply chain. That alignment makes engineering communication faster and reduces misunderstandings during quoting and PPAP-style submissions.

Precision Copper Busbars—Power Distribution That Stays Cool and Stable

Why Conductivity Data Matters in Busbar Design

In busbar engineering, the details are not optional. Electrical resistivity changes with temperature, purity, and processing history, which is why many engineers reference published measurement work when modeling losses or validating designs. NIST has published technical work on copper resistivity values across temperatures that engineers use as a credible reference point: NIST PDF—Electrical resistivity of copper (JPCRD reprint). NIST

A good busbar supplier translates those principles into practical manufacturing: stable flatness, consistent thickness, reliable hole-to-hole position, controlled burr direction, and plating choices that match your joint strategy. This is exactly where “every deep drawn breath” shows up—because joint reliability is often decided by small dimensional and surface details.

Where Busbars and Assemblies Meet Global Standards

If your copper busbars integrate into low-voltage assemblies or busbar trunking systems, compliance discussions often reference IEC 61439 series requirements. UL provides an overview of IEC 61439-1 and IEC 61439-6 and how verification requirements relate to LV busway systems: UL overview of IEC 61439-1 and IEC 61439-6. UL Solutions

We support customers with manufacturable designs and documentation discipline so the mechanical part supports the electrical system goals. That includes thickness control, plating specifications, joint surface finish expectations, and packaging methods that protect contact areas.

Deep-Drawn Components for Real-World Assemblies

When Deep Drawing Wins Over Machining or Welding

Deep drawing can deliver excellent strength-to-weight performance, clean surfaces, and high repeatability—especially for cups, shells, covers, EMI housings, sensor bodies, and enclosure components. In many designs, deep drawing reduces weld seams and machining time while improving cosmetic consistency.

The key is choosing deep drawing for the right geometry and production volume. When it fits, the process produces parts that feel “inevitable”—as if the metal always wanted to become that shape.

Consistency Is Built on Controlled Variables

A deep-drawn part that fits perfectly in the lab but fails in production is a process-control problem, not a luck problem. We focus on stable blank prep, repeatable lubrication methods, controlled draw conditions, and die maintenance schedules that protect critical surfaces and radii.

This discipline is what we mean by every deep drawn breath—a process that behaves the same way today, next month, and next year.

Precision Stamping Dies—The Hidden Engine Behind Reliable Parts

Why Die Engineering Determines Part Quality

A precision stamping die is not just a tool; it is a system that must manage alignment, wear, stripping force, cutting clearance, and material flow behavior. Even when the press is strong, die design is what controls edge quality, burr direction, and dimensional repeatability.

For buyers, that means one simple truth: the cheapest die often becomes the most expensive program. Tool life, ease of maintenance, and stable capability matter more than a low initial number.

Tooling Strategy: Progressive, Transfer, or Hybrid Approaches

Progressive die stamping can be ideal for repeatable features, controlled feeding, and high-volume production. Transfer or multi-stage approaches may be better when draw depth, part handling, or geometry complexity exceeds what progressive stations can manage economically.

We help customers choose the approach that matches their long-term goals, not just the fastest prototype route. That protects your program from painful redesigns during scale-up.

Inspection and Process Control—How We Make Quality Measurable

Measuring the Features That Actually Matter

Not every dimension is equally important, and not every cosmetic detail is worth the same cost. We work with customers to identify CTQs (critical-to-quality characteristics) that affect sealing, assembly fit, conductivity contact, or functional alignment.

Then we build inspection routines around those CTQs using appropriate gauges, CMM checks when required, and in-process verification to catch drift before it becomes scrap. Quality becomes an engineered system, not a final-step hope.

Traceability and Documentation for Global OEMs

For many programs, traceability is a practical requirement—not a marketing claim. Lot control, material certificates, plating records, and revision control help customers manage audits, reduce field risk, and respond quickly if any question arises.

This is another place “every deep drawn breath” becomes real: documentation that matches the physical product, and process data that proves consistency.

Surface Finishing—Coatings, Cleanliness, and Contact Reliability

Finishes That Support Function, Not Just Appearance

Surface finishing decisions should match real functional needs: corrosion resistance, solderability, contact stability, or cosmetic branding. For copper busbars, plating such as tin or nickel is often selected to support joining and long-term stability, while deep-drawn shells may need passivation, polishing, or controlled surface texture.

We treat finishing as a continuation of precision manufacturing, not a separate afterthought. That means controlled handling, clean packaging, and process settings that avoid scratches or contamination.

Why Cleanliness Is a Performance Variable

For electrical and sealed components, cleanliness affects assembly yield and long-term reliability. Oils, particles, or inconsistent film residues can change contact resistance, interfere with adhesives, or compromise sealing surfaces.

Stable cleaning and packaging are part of the same rhythm as forming and stamping. Quality is a chain, and every link must breathe the same standard.

Compliance and Quality Systems for Global Markets

Quality Systems That Customers Recognize

Many global buyers align suppliers with recognized quality management systems. ISO describes ISO 9001 as a globally recognized quality management standard that helps organizations meet customer expectations and improve performance: ISO 9001:2015 (ISO.org). ISO

For automotive supply chains, some programs also reference IATF 16949 expectations depending on the customer and product scope. The IATF Global Oversight site provides background on IATF 16949 and its role in harmonizing automotive QMS requirements: IATF 16949 overview (IATF Global Oversight). IATF Global Oversight

Environmental Compliance for Electronics and EEE Products

If your deep-drawn housings or copper busbars go into electrical/electronic equipment, RoHS is often part of compliance planning for EU markets. The European Commission provides an official overview of the RoHS Directive and its purpose in restricting hazardous substances: European Commission—RoHS Directive. Environment

Compliance is not only paperwork; it influences material selection, plating chemistry choices, and supplier documentation discipline. That is why we treat compliance as a design and sourcing strategy, not a late-stage scramble.

Applications—Where Deep-Drawn Parts and Copper Busbars Create Real Value

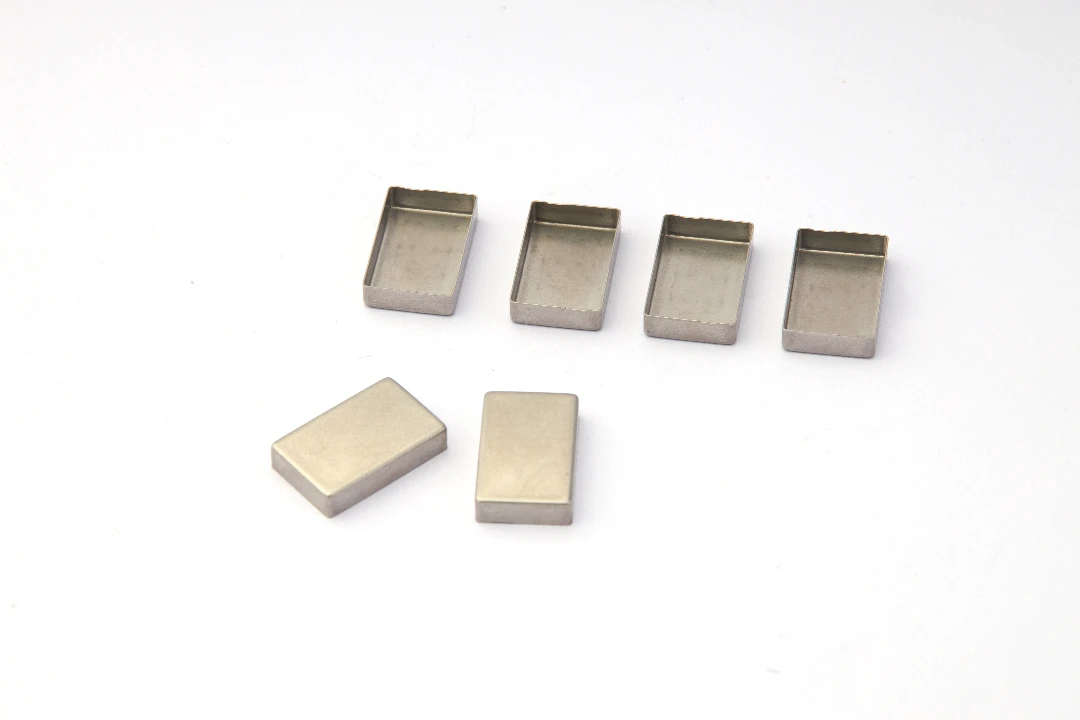

Electronics, EMI Shielding, and Precision Housings

Deep-drawn shells and covers are widely used when you need consistent walls, clean surfaces, and repeatable fit. With the right geometry and tooling, deep drawing supports high-volume production while maintaining a premium look and tight assembly control.

For EMI-related housings, stable form and consistent seams often matter more than people realize. When parts distort, you don’t just lose cosmetics—you can lose shielding effectiveness and sealing performance.

Energy, EV, and High-Current Power Distribution

Copper busbars support compact power distribution, inverter systems, battery packs, charging systems, and industrial power cabinets. In these applications, small dimensional errors can become big thermal or assembly problems, especially at scale.

This is why we focus on repeatability, surface control, and engineering collaboration. High current systems demand parts that behave predictably, not parts that merely pass a quick visual check.

Partnering With JUMAI TECH—From RFQ to Delivery

A Simple, Practical RFQ Path

A fast and accurate quote depends on clear inputs: drawings (2D/3D), material and temper, thickness, tolerances, surface requirements, annual volume, and packaging expectations. When those details are defined early, we can recommend the right forming route, tooling plan, and inspection approach without guesswork.

If something is unclear, we don’t hide it inside assumptions. We flag it early—because stable production is built on clear communication.

The Promise Behind “Every Deep Drawn Breath”

Every deep drawn breath is our commitment to repeatability: engineered tooling, controlled process windows, measurable inspection, and documentation that stands up to global OEM expectations. Whether you need custom precision copper busbars, deep-drawn components, or precision stamping dies and spare parts, our goal is to help your program launch smoothly and run reliably.

If you want a supplier who treats quality as a process—not a slogan—JUMAI TECH is ready to support your next design with the discipline it deserves.

FAQ

What does ‘Every Deep Drawn Breath’ mean?

‘Every Deep Drawn Breath’ refers to the process of ensuring quality in metal forming. It means every step in creating a part—from selecting materials to making the finished product—is carefully controlled and repeated. This attention to detail helps ensure that parts are reliable and work as intended.

How does deep drawing work?

Deep drawing is a method used to shape metal into hollow parts. It starts with a flat piece of metal, which is pressed into a mold to create the desired shape. The process requires careful control to avoid problems like wrinkles or tears in the metal.

Why is selecting the right material important?

Choosing the right material is crucial because it affects how well the part can be made. For example, materials like copper are great for conductivity, but things like thickness and surface quality also matter. The right choices lead to better performance and durability.

What are precision copper busbars?

Precision copper busbars are metal strips made from copper used in electrical systems to distribute power. They are designed to reduce heat and ensure stable electrical connections, making them essential in devices like electric vehicles and electronic equipment.

How do you ensure quality in production?

Quality is ensured through strict inspection processes and control methods during production. We focus on identifying the important features that affect how parts fit and function, using checks throughout the process to catch any issues before they become problems.

What are the benefits of deep-drawn parts?

Deep-drawn parts are strong, repeatable, and have clean surfaces. This process can be more efficient than welding or machining because it produces parts with less waste and often fewer seams, leading to a consistent look and performance.

Why is documentation important for global markets?

Good documentation helps ensure quality and compliance with international standards. It shows how materials were sourced and ensures that every step of the production process can be traced, which is vitally important for audits and safety.

How do you handle defects during production?

Instead of treating defects as bad luck, we view them as signals that something needs to be adjusted. By carefully analyzing the production process, we can make corrections to improve quality and ensure that future parts are made correctly.

What is the relationship between design and manufacturing?

The design of a part greatly affects how easily it can be manufactured. Good design considers how the metal will flow and fit together, reducing costs and ensuring that parts are made efficiently while maintaining quality.

What support does JUMAI TECH offer to its partners?

JUMAI TECH offers comprehensive support from the initial request for a quote to the final delivery. This includes clear communication, expert recommendations for material and tooling, and a commitment to producing reliable parts that meet the customer’s needs.