Sourcing busbar copper looks simple until an OEM program hits real-world pressure: heat rise limits, tight assembly tolerances, plating reliability, and supplier traceability audits. High-current busbars are unforgiving, and small differences in copper grade, temper, or surface condition can turn into big problems at commissioning or in the field. This guide breaks down a practical, OEM-friendly way to specify, qualify, and buy high-purity busbar copper—while keeping cost, lead time, and quality risk under control.

Table of Contents

Why “High-Purity” Matters in busbar copper

Electrical efficiency and heat rise start with the alloy

In switchgear, busway, battery packs, and power distribution cabinets, electrical loss becomes heat, and heat becomes derating or failure risk. “High-purity” busbar copper usually means commercially pure copper grades with very high conductivity, which reduces I²R losses and helps you pass temperature-rise verification more comfortably. Copper conductivity is commonly referenced using %IACS (International Annealed Copper Standard), where “100% IACS” is the historical benchmark for annealed copper. copper.org

Joining and forming reliability depend on oxygen content and cleanliness

OEMs often care about brazing, ultrasonic welding, diffusion bonding, or high-quality bolted joints with low contact resistance. Some copper grades (especially oxygen-bearing grades) can be more sensitive in certain joining processes, and surface contamination can destroy plating adhesion or raise contact resistance. When your assembly line needs stable torque-to-resistance results, purity alone is not enough—you also need consistent temper, flatness, and surface condition.

Plating and corrosion performance are “hidden” purity requirements

Many busbars are tin-plated or silver-plated for corrosion resistance, joint performance, or compatibility with aluminum lugs. Plating success depends on surface preparation, base-metal condition, and process discipline, not just the plating thickness on a drawing. If your busbar copper supply chain cannot control oxide films, handling marks, or embedded debris, you may see blistering, peeling, or inconsistent solderability even when copper chemistry is “correct.”

The most common copper grades used for busbar copper (and when to choose them)

C11000 (ETP) — the workhorse for general-purpose busbars

For many OEM projects, Electrolytic Tough Pitch copper (UNS C11000) is the default because it combines high conductivity, broad availability, and mature fabrication supply chains. Industry references commonly list C11000 as ~99.90% minimum copper content (chemistry varies by spec) and ~100% IACS minimum conductivity in annealed condition, which makes it a strong baseline for busbar copper programs. You can reference C11000 properties through the Copper Development Association alloy database here: C11000 alloy data. Copper Alloys

Oxygen-free grades (e.g., C10100/C10200) — when joining quality and purity margins matter

When an OEM program requires the cleanest copper for specific joining processes, high-vacuum applications, or very conservative impurity limits, oxygen-free grades are often evaluated. “Oxygen-free” can reduce risks related to hydrogen embrittlement in certain thermal/joining conditions, and it may offer tighter control on oxygen-related behavior. However, it can cost more and may have longer lead times, so it should be driven by real process needs rather than a vague “higher purity must be better” mindset.

“Pure copper” is not one thing—avoid vague RFQs

If an RFQ simply says “pure copper busbar,” suppliers may quote different grades, different tempers, and different standard baselines. That makes comparisons meaningless and increases the chance of late-stage engineering changes. A better approach is to specify the copper grade (UNS), the governing standard (ASTM/EN), the temper, and the required conductivity range—then treat plating and surface requirements as separate, controlled characteristics.

Standards and specifications you should reference in your busbar copper RFQ

ASTM B187/B187M is a common baseline for copper bus bars

If your OEM project is North America–centric (or your supply chain is), ASTM B187/B187M is widely used for copper bus bar, rod, and shapes. It defines requirements for copper conductor bars/rods/shapes and lists acceptable copper grades and tempers for bus applications. You can reference the standard overview here: ASTM B187/B187M. ASTM International | ASTM

EN/IEC references often show up in switchgear and busway ecosystems

If your project aligns with IEC-type assemblies, your overall system standard might reference verification methods, temperature-rise limits, and assembly expectations tied to IEC 61439 series. Even if you don’t buy IEC documents directly during sourcing, your customer may require compliance evidence in the PPAP/FAI package. UL also provides an accessible overview of how IEC 61439-1/61439-6 are used in LV busway contexts here: UL resource on IEC 61439-1/61439-6. UL Solutions

Use standards as a “contract language,” not as marketing words

The purpose of referencing ASTM/EN/IEC is to remove ambiguity from busbar copper sourcing. Standards turn “high purity” into testable requirements: chemistry windows, acceptable product forms, mechanical properties by temper, and basic quality expectations. Once your RFQ language is objective, you can qualify suppliers faster and reduce disputes when inspection results don’t match expectations.

How to define “high-purity” in busbar copper without overpaying

Start with chemistry that matches your joining and plating processes

For most OEM busbars, the key is to specify the correct UNS grade and require mill certification (MTR/CoA) tied to a heat/lot number. If your project truly needs a stronger purity margin, define it with measurable limits (e.g., oxygen content, total impurities, specific element caps) rather than simply demanding “99.99%.” The Copper Development Association’s technical materials discuss copper types and typical impurity/oxygen context in a way that helps frame these decisions. See: Copper types and properties background. copper.org

Specify conductivity using %IACS for apples-to-apples sourcing

If your electrical design needs predictable performance, put conductivity in your RFQ as a requirement (not just a “typical” value). CDA notes that conductivity is often expressed relative to IACS and that modern commercially pure copper can slightly exceed the historical 100% IACS baseline. You can reference the definition and context here: CDA conductivity / IACS explanation. copper.org

Don’t forget temper, because it changes forming and assembly behavior

Busbars are not only conductors—they are mechanical parts that must fit, hold shape, and survive vibration and thermal cycling. Temper affects bendability, springback, bolt joint stability, and flatness after processing. Make temper an explicit line item (and align it with your fabrication method), because “same copper grade” with different temper can behave like a different material on your factory floor.

Certificates, traceability, and compliance documents OEMs actually need

Mill Test Report (MTR) and lot traceability are your safety net

For OEM projects, you want every busbar copper shipment tied to a lot/heat with documented chemistry and key properties. This is how you avoid program-wide field risk when something goes wrong and you need to isolate affected builds. Traceability is also a supplier qualification signal: if a vendor cannot maintain lot discipline, they will struggle with consistent quality as you scale.

RoHS and REACH: handle them early, not after PO release

Many customers require declarations that materials comply with restricted substances rules, especially when busbars ship as part of an electrical assembly. For RoHS context, you can reference the European Commission overview page here: RoHS Directive overview. Environment

For REACH, ECHA provides official legislative background and responsibilities here: ECHA REACH legislation. European Chemicals Agency

Use a document matrix so suppliers can’t “forget” key items

Instead of chasing paperwork by email, define a simple document list inside the RFQ and PO: MTR/CoA, RoHS/REACH declarations (as applicable), dimensional inspection report, plating thickness report (if plated), and packaging/labeling requirements. This makes supplier performance measurable and reduces late shipments caused by missing approval documents.

Choosing the right sourcing model for busbar copper in OEM programs

Buy directly from a mill when volumes are stable and specs are tight

Direct mill sourcing can be cost-effective at scale and can improve traceability and consistency. It also typically increases MOQ, adds schedule constraints, and pushes you to forecast demand earlier. If you have long-term contracts and predictable build plans, direct mill is often the most stable route for high-volume busbar copper.

Use service centers for flexibility and faster turnaround

Service centers can cut plate, slit coil, or provide standard bar sizes with shorter lead times. The tradeoff is that traceability and property guarantees may depend on how well the service center manages lot separation and documentation. If your program is in prototype-to-ramp mode, service centers can keep you moving while your final spec stabilizes.

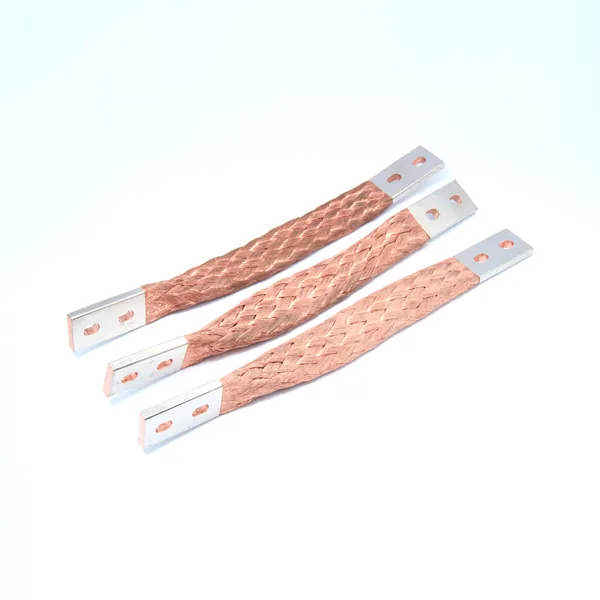

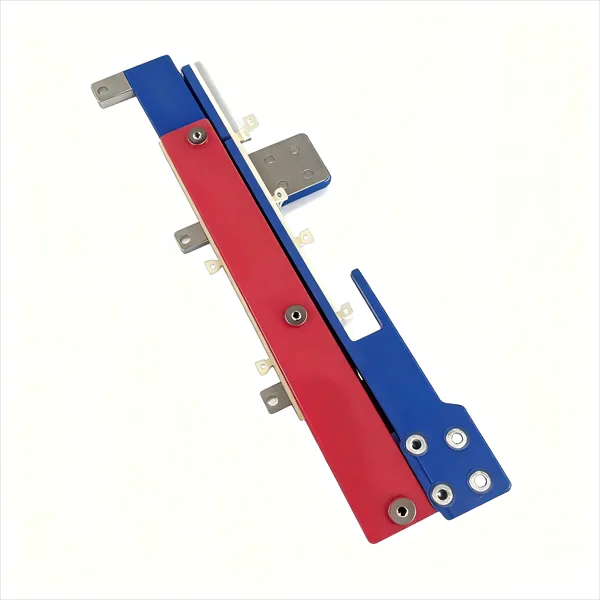

Partner with a fabricator when you need “ready-to-assemble” busbars

Many OEMs don’t really want to “buy copper”; they want busbars that fit, assemble quickly, and pass test the first time. A qualified fabricator can integrate busbar copper sourcing, cutting, stamping, bending, deburring, plating, and inspection into one controlled flow. This reduces supplier count, reduces tolerance stack-ups, and improves accountability when the final assembly is what matters.

Fabrication factors that can make or break busbar copper performance

Cutting and edge quality affect both safety and electrical contact

Poor cutting methods can create burrs, edge cracks, or heat-affected zones that later become corrosion sites or assembly hazards. High-quality busbar copper fabrication emphasizes controlled burr direction, consistent edge radius (when specified), and repeatable dimensional stability. If your busbar interfaces with insulation barriers or tight-clearance busway housings, edge discipline becomes a functional requirement, not a cosmetic preference.

Forming and bending require correct temper and process control

Busbars often need precise offsets, Z-bends, or multi-step forming to route around components. If temper is too hard, you get cracking or uncontrolled springback; if too soft, you may get distortion and tolerance drift after handling. A good supplier will talk about bend radius, grain direction, and tooling approach in practical terms—not just say “we can bend copper.”

Surface preparation is the foundation of plating reliability

Tin and silver plating are common for busbar copper to improve corrosion resistance and contact performance. But plating only performs as well as the base surface preparation: cleaning, activation, and handling. If you’ve ever seen blistering or peeling, it usually traces back to surface condition control, not just the plating chemistry.

Annealing and heat effects can change flatness and mechanical behavior

Thermal processes (including stress relief, brazing, or plating-related heating) can change grain structure and hardness, which can affect bolt torque retention or dimensional stability. For critical OEM projects, it’s smart to require first-off samples made with production-equivalent processes, not “prototype shortcuts.” That is how you prevent “it worked in samples” problems during ramp.

Incoming inspection and quality tests for OEM busbar copper programs

Verify conductivity when performance margins are tight

If your design is near thermal limits or current density is aggressive, conductivity verification becomes valuable. Some OEMs use eddy current conductivity meters or defined test coupons for 4-point measurements, especially when switching copper grades or suppliers. Even a simple “minimum %IACS” requirement helps drive consistency and prevents silent substitution in the busbar copper supply chain.

Check thickness, hole location, and flatness like an assembly engineer

Busbars fail in assembly more often than they fail electrically. Hole position, slot width, offset angles, and overall flatness directly affect fit-up time and rework rate. A strong supplier will provide dimensional reports for critical-to-assembly features and will understand where your tolerance stack-up is most sensitive.

For plated busbars, measure thickness and adhesion—not just appearance

Plating thickness is measurable, and you can specify the test method or sampling plan. If your application is sensitive (high humidity, marine, outdoor cabinets), adhesion and porosity considerations matter too. Build your acceptance criteria around function and testability, not around “looks good.”

Packaging, storage, and logistics: the overlooked part of busbar copper sourcing

Copper surfaces are easy to damage and hard to “un-damage”

Handling scratches, fingerprints, and oxide films can turn into higher contact resistance or plating defects later. Packaging should protect surfaces, prevent rubbing, and keep parts clean enough for the next process step. For OEM lines, consistent packaging orientation also saves time because operators don’t have to “figure out” how parts are nested.

Moisture control and labeling prevent field failures and line stoppages

If copper sits in humid environments, oxidation can accelerate, especially on freshly processed edges. Add moisture barriers when needed and make labeling unambiguous: part number, revision, lot/heat, quantity, and traceability references. A simple, disciplined label format is often the difference between a smooth kitting operation and a quality hold.

Think global: customs, pallet standards, and damage risk

For international OEM supply chains, packaging must survive long transit, multiple handling points, and variable climates. This is where a supplier’s export experience matters as much as their ability to cut copper. If the supplier is used to OEM documentation and global shipments, your busbar copper program will have fewer surprises.

Cost, lead time, and risk management in high-purity busbar copper

Copper price volatility is real—manage it like a program risk

Copper markets fluctuate, which can swing raw material cost and affect quoting validity windows. A mature sourcing approach uses pricing validity periods, optional price adjustment clauses, or scheduled price reviews. This keeps relationships stable and prevents “surprise” re-quotes mid-program.

Lead time is often driven by product form and temper, not just “availability”

If you need a specific thickness, width, temper, or surface finish, lead time can expand quickly, especially when mills require rolling schedules. The earlier you lock your true requirements, the less you pay in expedite fees and engineering churn. This is another reason to avoid vague “high purity busbar copper” language in early RFQs.

Dual-source strategy should focus on spec discipline, not supplier count

Dual sourcing works only when both suppliers build to the same objective specification and process expectations. If Supplier A interprets “high purity” differently than Supplier B, you don’t have a dual source—you have two different products. Use standards, MTR requirements, and first-article validation to make dual sourcing real.

A practical RFQ checklist for busbar copper (OEM-ready)

Material and standard callouts to include

- Copper grade / UNS number and standard reference (e.g., ASTM B187/B187M). ASTM International | ASTM

- Required conductivity (e.g., minimum %IACS) with measurement expectations, aligned with CDA guidance on IACS usage. copper.org

- Temper (soft/annealed vs hard) and any stress-relief/heat-treatment expectations that affect forming.

Drawing and fabrication details that reduce assembly pain

Define burr direction or maximum burr height, edge radius requirements (if any), and critical flatness zones near bolted joints. Include bend radii, angle tolerances, and any “no tool marks” zones for plated or contact areas. If you want plated busbars, specify base copper grade first and treat plating as a controlled secondary spec.

Quality and documentation expectations

Require MTR/CoA per lot, dimensional inspection reports for critical features, and plating thickness reports where applicable. Include RoHS and REACH declarations if your customer requires them, referencing official context pages like RoHS and ECHA REACH. Environment

First-off / sample plan (so ramp-up is smooth)

Ask for a small first-off batch made with production-equivalent tooling and processes. Define what “approval” means: fit check, torque test, contact resistance, plating verification, and visual standards. This prevents the common OEM trap where prototypes are handmade but production is tooled differently.

Why OEMs work with JUMAI TECH for precision busbar copper programs

Integrated sourcing + fabrication = fewer failure points

At JUMAI TECH (DeepDrawTech), we don’t treat busbar copper as a commodity box to tick. We treat it as the foundation of the finished part and the OEM assembly outcome, so the sourcing spec, fabrication method, surface prep, and inspection plan are aligned from day one. This reduces supplier handoffs, reduces tolerance drift, and improves accountability when your deadline is non-negotiable.

Precision stamping dies and deep-drawn expertise support scalable production

When an OEM program moves from prototype to volume, repeatability becomes the priority. Our experience in precision manufacturing—including Precision Stamping Dies and Deep-Drawn Components—supports consistent geometry control, stable process windows, and production-ready quality documentation. That means your busbar copper parts can scale without quality “surprises” hidden behind early samples.

OEM-friendly deliverables: samples, traceability, and global shipment readiness

We support structured RFQ communication, first-article workflows, and lot traceability expectations that OEM programs rely on. If your project needs ready-to-assemble busbars (cut/stamped/bent/plated/inspected), we can package the deliverables so your factory receives parts that go straight to kitting and assembly. When you’re ready, share your drawings and performance targets, and we’ll help you turn “high-purity busbar copper” into a clear, auditable, production-ready sourcing and manufacturing plan.